PUT THE BRAKES ON FAILURE

Page 124

If you've noticed an error in this article please click here to report it so we can fix it.

Fcry time a vehicle fails the annual F.; test it is recorded on the Vehicle

Inspectorate's (VI) computer against the operator's record. Gone are the days when vehicles were presented for test in order to find out what needed doing. Now this could pick up a string of black marks and prompt an investigation by the VI.

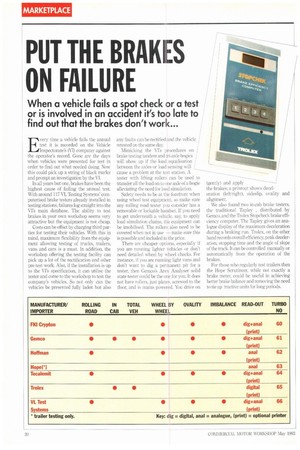

In all years but one, brakes have been the highest cause of failing the annual test. With around 117 VL Testing Systems' computerised brake testers already installed in testing stations, failures log straight into the VI's main database. The ability to test brakes in your own workshop seems very attractive but the equipment is not cheap.

Costs can be offset by charging third parties for testing their vehicles. With this in mind, maximum flexibility from the equipment allowing testing of trucks, trailers, vans and cars is a must. In addition, the workshop offering the testing facility can pick up a lot of the rectification and other pre-test work. Also, if the installation is up to the VI's specification, it can utilise the tester and come to the workshop to test the company's vehicles. So i at only can the vehicles be presented hilly laden but also any faults can be rectified and the vehicle retested on the same clay.

Mimicking the VI's procedures on brake testing tandem and n--axle bogies will show up if the load equalisation between the axles or load sensing will cause a problem at the test station. A Lester with lifting rollers can be used to transfer all the load on to one axle of a bogie alleviating the need for load simulation.

Safety needs to be at the forefront when using wheel test equipment, so make sure any rolling mad tester you consider has a removable or lockable handset. If you need to get underneath a vehicle, say, to apply load simulation chains, the equipment can be imobilised. The rollers also need to be covered when not in use — make sure this is possible and included in the price.

There are cheaper options, especially if you are running lighter vehicles or don't need detailed wheel by wheel checks. For instance, if you are running light vans and don't want to dig a permanent pit for a tester, then Gemco's Arex Analyser solid state tester could be the one for you. It does not have rollers, just plates, screwed to the floor, and is mains powered. You drive on (gently) and apply the brakes; a printout shows decel eration (left/right). sideslip, ovality and alignment.

We also found two in-cab brake testers, the traditional Tapley , distributed by Gemco, and the Trolex Stopcheck brake efficiency computer. The Tapley gives an analogue display of the maximum deceleration during a braking run. Trolex, on the other hand records overall efficiency, peak deceleration, stopping time and the angle of slope of the track. It can be controlled manually or automatically from the operation of the brakes.

For those who regularly test trailers then the Hope Scrutineer, while not exactly a brake meter, could be useful in achieving better brake balance and removing the need to tie up tract i ye units for long periods.