Trying thi hompson Trailmobile

Page 92

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

WHAT can one say about a semitrailer that has not been said before? That is a question which seems inescapable when evaluating this type of transport equipment, which has tended to settle into a fairly common pattern. Admittedly, the past three years or so have seen a spate of non-reactive running gears, while new and bigger designs were produced to meet the 1964 amendments to the C. and U. Regulations, but basically most generalpurpose trailers are very similar and it is only in the manufacturing methods that clear differences can be emphasized by the technical writer.

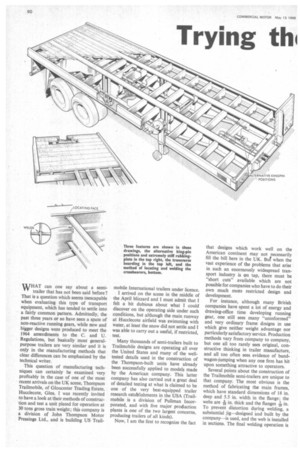

This question of manufacturing techniques can certainly be examined very profitably in the case of one of the most recent arrivals on the UK scene, Thompson Trailmobile, of Gloucester Trading Estate, Hucclecote, Glos. I was recently invited to have a look at their methods of construction and test a unit plated for operation at 30 tons gross train weight; this company is a division of John Thompson Motor Pressings Ltd., and is building US Trail mobile International trailers under licence.

I arrived on the scene in the middle of the April blizzard and I must admit that I felt a bit dubious about what I could discover on the operating side under such conditions, but although the main runway at Hucclecote airfield was swimming with water, at least the snow did not settle and I was able to carry out a useful, if restricted, test.

Many thousands of semi-trailers built to Trailmobile designs are operating all over the United States and many of the welltested details used in the construction of the Thompson-built units have already been successfully applied to models made by the American company. This latter company has also carried out a great deal of detailed testing at what is claimed to be one of the very best-equipped trailer research establishments in the USA (Trailmobile is a division of Pullman Incorporated, and with five major production plants is one of the two largest concerns, producing trailers of all kinds).

Now, I am the first to recognize the fact that designs which work well on the American continent may not necessarily fill the bill here in the UK. But when the vast experience of the problems that arise in such an enormously widespread transport industry is on tap, there must be "short cuts" available which are not possible for companies who have to do their own much more restricted design and development.

For instance, although many British companies have spent a lot of energy and drawing-office time developing running gear, one still sees many "uninformed" and very ordinary frame dr.signs in use which give neither weight advantage nor particularly satisfactory service. Production methods vary from company to company, but one all too rarely sees original, constructive thinking in trailer manufacture, and all too often sees evidence of bandwagon-jumping when any one firm has hit upon something attractive to operators.

Several points about the construction of the Trailmobile semi-trailers are unique to that company. The most obvious is the method of fabricating the main frames, which have standard dimensions of 18 in. deep and 5.5 in. width in the flange; the webs are 3 in. thick and the flanges lir in. To prevent distortion during welding, a substantial jig—designed 'and built by the company—is used, and the web is installed in sections. The final welding operation is

of making the butt-joints between the ons and 1 saw for myself that this tod produced an extremely straight ie without having to resort to straightg operations after welding.

ared from Stock rie panels that make up the web are luced in three standard sizes, all of :It can be sheared from stock-size sheet the least amount of wastage. After

g sheared to size, they are pierced for installation of cross-bearers, this zing being carried out by a punching s operation on a machine which can be to give various locations for flooring knesses from I to 1.5 in. The press tool esigned to give a positive location for top run of the cross-bearer, continuy accurate to plus or minus ala in, and viii be seen that this provides for emely accurate floor location. When frame is assembled, the main frames joined first by Z-section intermediate s-members. The cross-bearers are fed tugh the main frames and welded into ition. Here, a second important feature tat only the web of the cross-bearers is Jed to the main frame, and this only in corner on each side of the main-frame I. This allows for a high degree of zulation in the frame assembly, and is med to obviate much of the cracking of is between main members and crossnbers.

>ecking, when laid longitudinally is laid h with the tops of the main-frame ges and, because of the way in which

is done, does present some disadtages with regard to replacing of broken rds: several adjacent boards have to be loved to effect the removal of certain rds in the lay. I preferred the system d when the transverse flooring was plied, as this method provided extremely rt lengths of unsupported floor area. ers are placed longitudinally along the s of the cross-bearers, making up to the :1 of the main frame. The flooring is n laid across risers and main frame, I it will be seen that any one board can removed without the need to disturb immediate neighbour and that there is ubstantially increased measure of floor port.

lt.nother unusual feature of the Trailbile design is the method of installing king-pin. The usual practice of passing pin through the rubbing plate from we and bolting or welding it in position, mplaced by recessing the flange of the into the plate from the underside, ere it is then bolted up in the usual nner. A preference for a pin having a iare flange rather than the conventional :ular type stemmed from experience of Ling in the rubbing plate and insufficient ation of the flange via the bolts. The tare flange can be adequately and easily located, and by using the underside recess, two king-pin positiions can be supplied for use on TIR applications where the load space must remain sealed during a change of location.

The running gear is equipped with Rubery Owen 20,000 lb. axles, but the rest of the suspension is of Trailmobile design and manufacture. Silicon-manganese semielliptic leaf springs 40 in. long, with leaves 3.5 in. wide by 0.5 in. thick having a shotpeened surface, provide an extremely soft but roll-free ride. These are carried in slipper ends and instead of running on steel slipper plates the ends bear upon Delrin wearing pads.

Three-line System All spring brackets are forgings, and axles are located by rubber-bushed adjustable radius-rods. Three-line air-pressure braking with triple-diaphragm chambers is fitted on vehicles plated for operation at 22 tons (single axle) and 28, 30 and 32 tons (tandem axle). A Neate ratchet-and-drum parking brake is fitted, operating on both axles of the tandem units.

When carrying out the trailer test, a Guy Invincible tractive unit fitted with a Gardner 6LX engine was used. One of the first things that I noticed about the semi-trailer was the extremely short delay in the braking system, both application and release of the brakes being almost instantaneous. As I have already said, the conditions were very bad and I was aware of some degree of instability when doing short turns in the unladen condition. This was due to the tractive-unit rear axle trying to slide out of the turn in the form ola jack-knife which is, of course, to be expected under the conditions; when the vehicle was loaded the whole outfit could be put into an "eightwheel drift" without becoming unhandieable. Naturally, unladen stops from 20 and 30 m.p.h. using only the trailer brakes produced some pretty long stopping distances, with all the trailer wheels locking solid. The surprise came when the laden tests were done and the distances proved to be only a few feet longer than those recorded in the unladen tests, again with locked wheels.

Good Braking

Using only the trailer brakes, the unladen vehicle stopped from 30 m.p.h. in a total distance of 132.6 ft. and showed a Tapley meter reading of 27 per cent, whilst from 20 m.p.h. the recorded distance was 60 ft. with a Tapley reading of 29 per cent. Laden figures were, 135.3 ft. from 30 m.p.h., with 25 per cent on the Tapley, and 68.8 ft. from 20 m.p.h. with 24 per cent on the Tapley. Although the tractive unit (which had teen loaned for the test by R. W. Baker (Stonehouse) Ltd.), was not fitted with three-line braking it was a fair guess that a figure well in excess of the required 25 per cent for the secondary brakes would be obtained with the assistance of the steering-axle brakes. Fullpressure stops using all the brakes on the outfit recorded Tapley readings from 30 m.p.h. of 68 per cent when unladen and 53 per cent when loaded. I considered these to be very good under the conditions.

Carrying, as it was, a payload of 19 tons 5. cwts., the trailer showed no signs of sagging in the middle, and on the road performed in a docile and easily-handled manner. There was no tendency to lay in the gutter and no call for the constant correction which goes hand in glove with a distorted fifth-wheel plate. When the trailer was uncoupled, however, there was evidence that the plate was in fact distorted, and when I pointed this out to the Trailmobile engineers I was told that the particular unit incorporated a rubbing plate that was hand-smithed. Subsequent models are using machine-smithed plates but grinding is not ruled out as a future development.

Short-turning, carried out fully laden. showed the expected amount of wringing in the running gear and it was at this time that the extreme flexibility of the frame showed up. Watching the bogie twisting, the frame could be seen flexing quite considerably and I wondered what the effect might be on any superimposed bodywork that might be fitted.

Completing the short turns, I put the outfit through reversing and figure-eight routines—which very quickly show up any permanent distortion in running gear alignment. All these were successful, apart from a tendency for the outfit to run slightly to the right when reversing in a straight line and to tend to run out of a reverse left-hand circle. Both these occurrances pointed to slight misalignment of one or other of the trailer axles. As neither of these tendencies showed up when the same tests were carried out in the unladen condition, I came to the conclusion that some adjustment was needed on the radius rods for the laden condition.

Returning the semi-trailer to the factory, I carried out a droop test over the landing gear, which was positioned 11 ft. from the headboard; with exactly 7 tons evenly loaded forward of the legs, the neck of the trailer dropped 2.5 in. when the tractive unit was removed. I was not particularly happy with the fitting of the landing gear on the test trailer, and when I broached the subject with the engineers was told that this was a point that was receiving attention with some urgency, as they also were not happy with the present arrangement.

Flatbed, sided and frameless boxvan semi-trailers are included in the company's range of products and the model tested, No. TT.25/30, has a basic list price of £1,801 10s. fitted with 9.00-20, 14-ply tyres and standard 2.5 ft. headboard.