Planning the Ideal Garage Layout

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

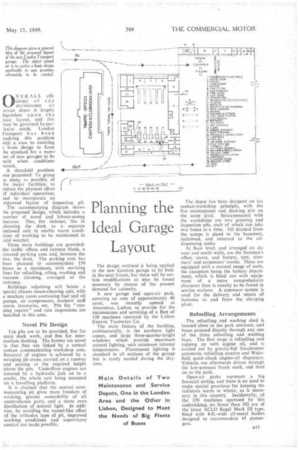

OVERALL efficiency of an y maintenance o r ervice depot is largely lependent upon the iasic layout. and this nust be governed by paricular needs. London Fransport h as b een itudying this problem with a view to evolving t basic design to form he standard for a numaer of new garages to be auilt when conditions )ermit.

A threefold problem was presented: To group is many as possible of he major facilities; to reduce the physical effort af individual operatives; Ind to incorporate an mproved layout of inspection pit.

The accompanying diagram shows :he proposed design, which includes a lumber of novel and labour-saving eatures. One, for instance, lies in planning the dock as a separate enclosed unit to enable warm conditions of working to be maintained in ;old weather.

Three main buildings are provided: the traffic offices and canteen block, a :ovcred parking area and, between the two, the dock. The parking area has been planned to accommodate 150 buses as a maximum, with servicing lines for refuelling, oiling, washing and vacuum cleaning, arranged at the entrance.

Buildings adjoining will house a special chassis steam-cleaning unit, with a machine room containing fuel and oil pumps, adr compressors, washers' staff room, lavatories, etc. Pits for "running repairs" and rota inspections are installed in this area.

Novel Pit Design

Ten pits are to be provided, five for main dock work, and five for intermediate docking. The former are novel in that they are linked by a central sunken communicating workshop area. Removal of • engines is achieved by a swinging jib crane, carried on a runway and passing at the required height above the pits. Underfloor engines are lowered by a hydraulic jack on to a cradle, the whole unit being mounted on a travelling platform.

It is claimed that the central communicating pit gives more freedom of working, greater accessibility of all under-chassis parts, and a more even distribution of natural light. In addition, by avoiding the tunnel-like effect of the orthodox type of pit, improved working conditions and supervisory control are made possible. The design outlined is being applied to the new Garston garage to be built in the near future, but there will be certain modifications as may be found necessary by reason of the present demand for austerity.

A new garage and open-air park, covering an area of approximately 40 acres, was recently opened at Amoreiras, Lisbon, to provide for the maintenance and servicing of a fleet of 150 machines operated by the Lisbon Electric Tramways Co.

The main feature of the building, architecturally, is the northern light aspect, and large three-quarter-height windows which provide maximum natural lighting, with minimum internal temperatures. Fluorescent lighting is standard in all sections of the garage but is rarely needed during the daytime. The depot has been designed on the sunken-workshop principle, with the five maintenance and docking pits on the same level. Interconnected with the workshops are two greasing and inspection pits, each of which can take two buSet at a' time. Oil drained from the sumps is piped to the basement, reclaimed, and returned to the oildispensing tanks.

At floor level, and arranged on the west and north walls, are the foreman's office, stores, and battery, tyre, trimmers' and carpenters' rooms. These are equipped with a normal range of tools, the exception being the battery department, which is fitted out with equipment of a more comprehensive character than is usually to be found in service stations. A conveyor system is used for the delivery and return of batteries to and from the charging plant.

Refuelling Arrangements

The refuelling and washing shed is located close to the park entrance, and buses proceed directly through any one of the three refuelling and washing bays. The first stage is refuelling and topping up with engine oil, and is carried out by gravity-fed Tecalemeter automatic refuelling nozzles and Wakefield quick-check engine-oil dispensers. Vehicles are afterwards driven through the low-pressure brush wash, and theri on to the park.

Open-air parks represent a big financial saving, and there is no need to make special provision for keeping the radiators warm in winter, as is necessary in this country. Incidentally, of the 150 machines operated by this undertaking,. no fewer than 102 are of the latest ACLO Regal Mark III type, fitted with 8-ft.-wide all-metal bodies designed to accommodate 45 passengers.