ROADTEST MAN 30.262

Page 30

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

• It's a long time since Commercial Motor last had its hands on an MAN eight-legger. We only tested one such truck in the 1980s, and that was in a tipper group test at the very start of the decade (CM 19 April 1980). The last full roadtest was as long ago as 7 October1977 when we tested a 30.232 VFK which is the direct ancestor of the current MAN eight-leggers.

Since then sales of the big Bavarians have risen steadily: throughout the 1980s the 8x4 outsold many of its stablemates to peak at 182 vehicles in 1989 before the recession demolished the tipper market. MAN took 6.1% of the market that year, down from 9.8% in 1986, when it took fourth place behind Volvo, Leyland Daf and Foden. In the process its eight-leggers gained a reputation for ruggedness and durability.

Outwardly, little has changed since our 1977 test. The current cab, shared with the F90 tractive unit range, is clearly derived from the earlier vehicle. The biggest differences are under the floor, where there is a choice of five or six-cylinder diesels developing 191kW (256hp), 212kW (285hp) and 242kW (325hp) respectively. The current F90 four-axle chassis was introduced in October 1989 when the five-cylinder 30.262 replaced the previous 177kW 237hp) six-cylinder 30.240 engine.

Our test vehicle this week is a 191kW 30.262 VFN, kindly loaned to us by Sheffield Auto Hire. Its power output may be conservative by modern eight-legger standards (55% of sales in 1990 were over 205kW/275hp), but its 9.97-litre diesel five-cylinder motor does offer potential weight savings over the heavier six-cylinder 12-litre engine used in the more powerful 30.292 and 30.332 models. Moreover, as the 30.262's five-pot now produces up to 235kW (320hp) in the F90 tractive unit, it could also replace the six-cylinder engine in the 8x4.

• BODYWORK

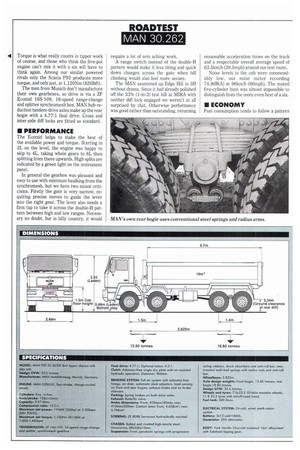

A quick glance at our payload figures shows the 30.262 is no featherweight. One reason for this is the MAN's substantial chassis, made from bolted and rivetted high-tensile steel.. Its deep sections (deeper than any of our listed rivals) provide off-road durability but with an inevitable weight penalty. Predictably, this results in a high unladen weight — 9,215kg with a full tank of fuel, leaving a comparatively low body/payload allowance of 21.275 tonnes.

Alloy wheels and body would increase the payload potential. Our test vehicle, destined for a hard life on a rental fleet, was equipped with a York Neville Charrold insulated 16m3 alloy-steel body and Telehoist SG152 tipping gear. The 5.825m wheelbase slots between 5.625 and 6.525m options.

The N-type day cab is finished as standard in white gloss. A hydraulic tilt lifts it through 60° to give access to the engine; all daily checks can be made behind the lifting front panel. This is made of plastic and the steel cab carries a five-year, unlimited distance warranty against rusting through.

• DRIVELINE The charge-cooled D2865LF engine produces 1,100Nm (8111bft) of torque between 1,000 and 1,480rpm (to DIN 70020).

Torque is what really counts in tipper work of course, and those who think the five-pot engine can't mix it with a six will have to think again. Among our similar powered rivals only the Scania P93 produces more torque, and only just, at 1,120Nm (8261bft).

The men from Munich don't manufacture their own gearboxes, so drive is via a ZF Ecornid 16S-109, 16-speed range-change and splitter synchromesh box. MAN hub-reduction tandem-drive axles make up the rear bogie with a 4.77:1 final drive. Cross and inter-axle cliff locks are fitted as standard.

• PERFORMANCE

The Ecomid helps to make the best of the available power and torque. Starting in 2L on the level, the engine was happy to skip to 4L, taking whole gears to 6L then splitting from there upwards. High splits are indicated by a green light on the instrument panel.

In general the gearbox was pleasant and easy to use with minimum baulking from the synchromesh, but we have two minor criticisms. Firstly the gate is very narrow, requiring precise moves to guide the lever into the right gear. The lever also needs a firm tap to take it across the double-H pattern between high and low ranges. Necessary no doubt, but in hilly country, it would require a lot of arm aching work.

A range switch instead of the double-H pattern would make it less tiring and quick down changes across the gate when hill climbing would also feel more secure.

The MAN sauntered up Edge Hill in 3H without drama. Since it had already polished off the 33% (1-in-3) test hill at MIRA with neither diff lock engaged we weren't at all surprised by that. Otherwise performance was good rather than outstanding, returning reasonable acceleration times on the track and a respectable overall average speed of 63.5km/h (39.5mph) around our test route.

Noise levels in the cab were commendably low, our noise meter recording 74.9dB(A) at 96km/h (60mph). The muted five-cylinder hum was almost impossible to distinguish from the more even beat of a six.

• ECONOMY

Fuel consumption tends to follow a pattern around our tipper test route, with the higher average speeds on the motorway section being offset by constant-speed running. Consequently most vehicles use less fuel on the motorways than on the A-roads.

Not so the MAN. On the motorway, cruising at 96km/h, the rev counter needle was just clear of the green sector and over this section we recorded 38.85k/100km (7.27mpg). On the A-road section, where the revs were mostly in the peak torque band, consumption dropped to 34.731it/100km (8.13mpg), giving an overall figure of 36.391it/100km (7.76mpg).

Curiously, we had a similar experience in our 1977 test of the 30.232. As then, this must be due to the gearing. Since most tipper work involves short distance A-road running MAN's choice of 4.77:1 rear axle ratios is probably better suited to its likely operating conditions than to our test route. Comparing A-road consumption with the rivals in our chart the MAN has one of the lowest figures, while overall it's a little higher than average.

• HANDLING

With a stout chassis to aid roll stiffness the MAN is off to a good start. The steel suspension is not particularly unusual, comprising springs at the front with multi-leaf inverted springs and radius rods for the rear bogie. Front and rear anti-roll bars certainly help its on-road behaviour without hampering suspension movement on rough ground.

Ride comfort is further improved by fourpoint cab suspension and an air suspended driver's seat which can be locked out over poor surfaces. Our test vehicle was shod with Bridgestone V Steels (MIX 757s on the steering axles and LUG 301s on the drive axles). They provided plenty of grip

..... -1 44 dusty quarry and .. ............. a?" 1997 out on the road. The 2F

power-assisted steering effec tively combines the right amount of assistance with adequate feedback from the front wheels.

Our experience with exhaust brakes has not always been too good. They all make the right noises but few of them appear to have any noticeable effect. Thumbs up to MAN then for producing one that provides some obvious retardation. The rest of the braking system gives no cause for complaint either.

On road and track the service brakes provided plenty of stopping power, while the parking brake showed it was equal to the 30.262's restart capability, holding it without fuss on the 33% (1-in-3) test hill.

• INTERIOR

The rear windows help make the N-type day cab feel light and airy, as well as helping with rear-three-quarter visibility. With a deep windscreen, triple wipers and heated door minors too, visibility is good.

Most drivers should be able to find a comfortable driving position. The seat is adjustable in all necessary directions and the steering column adjusts vertically. Crosscab access is not too good as the central hump extends forward to the dashboard, but the electric passenger side window has a dash mounted switch on the driver's side.

The interior is sensibly trimmed in grey with a cream headlining and check finish to door panels and seats. It's pleasing to the eye and should be easy to keep clean; rubber mats cover the floor.

Hoarders will love the MAN cab. Door pockets both sides have mouldings for a flask. The headlining contains a locker and map stowage. Between the seats a large box is big enough to hold several months supply of Commercial Motor useful for M25 travellers. Its lid provides a flat writing surface and there's a moulded tray behind it. Finally, there's yet another pocket across the back of the cab.

Instruments and controls are well

thought out too. The instruments are angled towards the driver, grouped around a large bank of warning lights and the tacho and rev counter are both large and easy to read.

• SUMMARY

This MAN is a hard vehicle to fault. Although it sets no new class standards it's a very good all-rounder. Where durability is an important factor, it scores highly. Rugged construction and a comparatively large, lightly stressed engine will appeal to many operators. Its gearing is well suited to most tipper work, striking a reasonable balance between performance and economy_

Its ruggedness is also its weakness weight-sensitive operators will not be attracted by the heavy chassis-cab. This is its only serious drawback, however, and it has not been a sales deterrent in the past.

Priced against its rivals in our comparison chart the MAN offers very good value. At £53,315 (ex-VAT) only the Volvo FL7 is cheaper, at £53,000 (ex-VAT). The ERF E8 is slightly more expensive at £53,750 (ex-VAT), closely behind the Leyland Dal FAD 80.260 at 254,150, making the Scania P93 look expensive at £56,706.

The MAN gets on with the job in a very businesslike fashion and anyone in the market for a moderately powered eight-legger might find it worth considering. Let's hope we get to test another before 2002.

CI by John Kendall