From the by Graham MontgomeriE

Page 82

Page 83

If you've noticed an error in this article please click here to report it so we can fix it.

The new Maxwell gearbox (CM June 6) designed for buses is an excellent design. There is potential here for a lorry gearbox in the future

S ANNOUNCED in last week's 44, there is a new gearbox on e market aimed specifically at e bus operator. It is the proJet of Maxwell Bus Transmisons Ltd of Soarbank Way, shop Meadow Road, Loughbough, run by Peter Windsornith, as far as the design is )ncerned; his partner Ray iilby is in charge of the producm side.

The gearbox of a bus and its ,mparative lack of reliability ompared with the rest of the .hide has been a thorn in the :le of fleet engineers for a long ne now. The career of Peter indsor-Smith has covered a de area of engineering design )rn lightweight petrol engines r motor racing to heavy-duty ?sels. For many years he was charge of bus engineering at limier and it was here that the rm of the idea came about.

Peter wanted to improve the iability of the Wilson type arbox for the Fleetline but the ly way to do this was by going a larger diameter drum and by increasing the band width over the two inches then in use. At the same time Gardner introduced the 6LXB engine which emphasised the fact that the gearbox was just too small for the job.

Another problem with the old Wilson type of box was the fact that all lubricant development work for automatic transmissions had been done with the Borg Warner type of box with little thought being given to units which used asbestos based bands. All this added up to total dissatisfaction with the gearbox.

So Peter Windsor-Smith decided to develop his own, tailored specifically for passenger vehicle operation.

The first scheme was to use some form of disc brake caliper but this was quickly rejected as it put offset loads into the gear train.

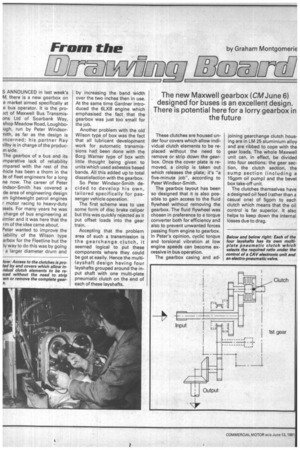

Accepting that the problem area of such a transmission is the gearchange clutch, it seemed logical to put these components where they could be got at easily. Hence the multilayshaft design having four layshafts grouped around the input shaft with one multi-plate pneumatic clutch on the end of each of these layshafts. These clutches are housed under four covers which allow individual clutch elements to be replaced without the need to remove or strip down the gearbox. Once the cover plate is removed, a circlip is taken out which releases the plate; it's "a five-minute job", according to Peter Windsor-Smith.

The gearbox layout has been so designed that it is also possible to gain access to the fluid flywheel without removing the gearbox. The fluid flywheel was chosen in preference to a torque converter both for efficiency and also to prevent unwanted forces passing from engine to gearbox. In Peter's opinion, cyclic torque and torsional vibration at low engine speeds can become excessive in bus operation.

The gearbox casing and ad

joining gearchange clutch housing are in LM 25 aluminium alloy and are ribbed to cope with the gear loads. The whole Maxwell unit can, in effect, be divided into four sections: the gear section, the clutch section, the sump section (including a 15gpm oil pump) and the bevel box take-off unit.

The clutches themselves have a designed oil feed (rather than a casual one) of 5gpm to each clutch which means that the oil control is far superior. it also helps to keep down the internal losses due to drag.

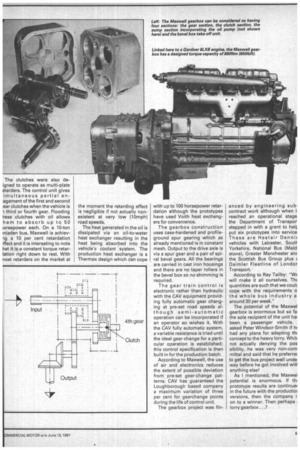

The clutches were also deigned to operate as multi-plate etarders. The control unit gives imultaneous partial enlagement of the first and second leafclutches when the vehicle is 'third or fourth gear. Flooding hese clutches with oil allows hem to absorb up to 50 iorsepower each. On a 10-ton inladen bus, Maxwell is achiev-ig a 10 per cent retardation :fleet and it is interesting to note hat it is a constant torque retarlation right down to rest. With nost retarders on the market at the moment the retarding effect is negligible if not actually nonexistent at very low (10mph) road speeds.

The heat generated in the oil is dissipated via an oil-to-water heat exchanger resulting in the heat being absorbed into the vehicle's coolant system. The production heat exchanger is a Thermax design which can cope with up to 100 horsepower retardation although the prototypes have used Voith heat exchangers for convenience.

The gearbox construction uses case-hardened and profileground spur gearing which as already mentioned is in constant mesh. Output to the drive axle is via a spur gear and a pair of spiral bevel gears. All the bearings are carried in cast iron housings and there are no taper rollers in the bevel box so no shimming is required.

The gear train control is electronic rather than hydraulic with the CAV equipment providing fully automatic gear changing at pre-set road speeds although semi-automatic operation can be incorporated if an operator so wishes it. With the CAV fully automatic system, a variable resistance is tried until the ideal gear change for a particular operation is established; this control specification is then built in for the production batch.

According to Maxwell, the use of air and electronics reduces the extent of possible deviation from pre-set gear-change patterns. CAV has guaranteed the Loughborough based company a maximum variation of three per cent for gearchange points during the life of control unit.

The gearbox project was fin anced by engineering sub• contract work although when reached an operational stage the Department of Transpor stepped in with a grant to heir put six prototypes into service These are Hestair Denni: vehicles with Leicester, SoutlYorkshire, National Bus (Maid stone), Greater Manchester anc the Scottish Bus Group plus Daimler Fleetline of Londor Transport.:

According to Ray Tailby: "W( will make it all ourselves. TM quantities are such that we coulc cope with the requirements o the whole bus industry a around 30 per week."

The potential of the Maxwel gearbox is enormous but so fa the sole recipient of the unit ha: been a passenger vehicle. asked Peter Windsor-Smith if ht had any plans for adapting th( concept to the heavy lorry. Whili not actually denying the pos sibility, he was very non-corn mittal and said that he preferre( to get the bus project well unde way before he got involved witl anything else!

As I mentioned, the Maxwel potential is enormous. If till prototype results are continue( in the future with the productioi versions, then the company i on to a winner, Then perhaps , lorry gearbox ...?