IN THE REPAIR SHOP.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Practices Followed by Our Driver and Mechanic Readers.

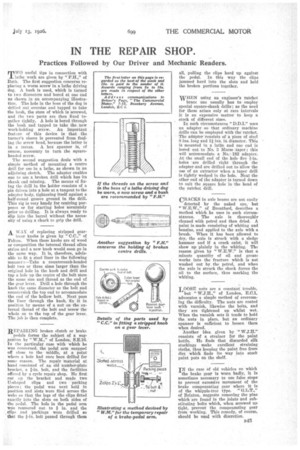

MAYO useful tips in connection with 1 lathe work are given by " F.H,," of Bath. The first suggestion concerns replacing a worm screw in a lathe driving dog. A bush is used, which is turned to two diameters and bored at one end as shown in an accompanying illustration. The hole in the boss of the dog is drilled out oversize and tapped to take the bush, the stem of which is screwed, and the two parts are then fixed together tightly. A hole is bored through the hush and tapped to take the new work-holding screw. An important feature of this device is that the turner's sleeve is prevented from fouling the screw head, because the latter is in a recess. A box spanner is, of course, necesSary to turn the squareheaded screw.

The second suggestion deals with a simple method of mounting a centre drill for use in a lathe, as shown in an adjoining sketch. The adapter enables one to use a broken drill which has its shank end missing. The means of fixing the drill in the holder consists of a pin driven into a hole at a tangent to the adapter body, tightening itself against a half-round groove ground in the drill. This rig is very handy for centring purposes or for starting holes accurately prior to drilling. It is always ready to slip into the barrel without the necessity of using a chuck to grip the drill.

-A WAY of replacing stripped gear lever knobs is given by " CC.," of Felton. When these knobs are of wood or composition the internal thread often strips and a new knob would soon go in the same way. It is, therefore, advisable to fit a steel liner in the following manner :—Take a countersunk-headed bolt two or three sizes larger than the original hole in the knob and drill and tap a hole up the centre of the bolt stem the same size and thread as the end of the gear lever. Drill a hole through the knob the same diameter as the bolt and couetersink the top end to accommodate the cad of the hollow bolt. Next pass the liner through the knob, fix it in position by means of a nut on the external thread of the bolt and screw the whole on to the top of the gear lever. The job is then complete.

REPAIRING broken clutch or brake

Pedals forms the subject of a suggestion by " W.1V1.," of London, SE.16. In the particular case with which he was concerned, the pedal arm snapped off close to the middle, at a point where a hole had once been drilled for some reason. The repair material at hand consisted of an old numberplate bracket, a 4-in, bolt, and the facilities offered by a cycle repair shop. He first cut up the bracket and made two 15-shaped clips and two packing pieces ; the pedal was next held in position and slots were filed across the webs so that the legs of the clips fitted exactly into the slots on both sides of the pedal. The hole in the pedal arm was reamered out to 4 in. and the .clips and 'packings were drilled so that the i-in. bolt passed through them

all, pulling the clips hard up against the pedal. In this way the clips jammed hard into the slots and held the broken portions together.

WHEN using an engineer's ratchet brace one usually has to employ special square-shank drills; as the need for these arises only at rare intervals it is an expensive matter to keep a stock of different sizes.

In such circumstances "D.D.I." uses an adapter so that ordinary machine drills can be employed with the ratchet. The adapter `consists of a piece of steel 8 ins, long and 1i ins, in diameter. This is mounted in a lathe and one end is bored out to No. 3 Morse-taper ; this will aceommodate a No: 182 adapter. At the small end of the hole •five fin holes are drilled right through the adapter and are drifted out to allow the use of an extractor when a taper drill is tightly wedged in the hole. Next the other end of the adapter is turned down to suit the square hole in the head of the ratchet drill.

CRACKS in axle beams are not easily

detected by the naked eye, but "W.E.W.," of 13rentford, describes a method which he uses in such circumstances. The axle is thoroughly cleaned with petrol and then dried. A paint is made consisting of whiting and benzine, and applied to the axle with a brush. 'When it has been allowed to dry; the axle is struck with a sledge hammer and if a crack exist, it will show up plainly in the whiting. The reason given by " VT.E.W." is that a minute quantity of oil and grease works into the fracture which is not washed out by the petrol, and when the axle is struck the shock forces the oil to the surface, thus marking the whiting.

LOOSE nnts are a constant trouble, but " W.J.H.," of London, E.C.1. advocates a simple method of overcoming the difficulty. The nuts are coated with varnish, likewise the bolts, and they are tightened up whilst wet. When the varnish sets it tends to hold the nuts in place, but an ordinary spanner is sufficient to loosen them when desired.

Another idea given by "W.J.H." consists of a strainer for the paint kettle. He finds that discarded silk stockings make excellent straining cloths, thus beeping the paint free from dirt which finds its way into stock paint pots on the shelf.

IN the case of old vehicles on which

the brake gear is Worn badly, it is sometimes necessary to use false stops to prevent excessive moVement of the brake compensating gear where it is of the whipple-tree type. " G.L.T.," of Brixton, suggests removing the pins which are found in the joints and substituting bolts which, when screwed up tight, prevent the compensating gear from working. This remedy, of course, should be used with discretion.