A SIX-WHEELER WITH CREEPER TRACKS.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

First Published Details of a New Morris Product for Transport in Rough and Undeveloped Country.

IN designing the remarkable rigidframe six-wheeler which they have just placed upon the market Morris 'Commercial Cars. Ltd., have had certain definite objects in view; perhaps the most important of these is the provision of a type of vehicle which will effectively meet the requirements of potential users abroad, and particularly in the Colonies, where there exists an urgent need for a means of transport far more flexible and far less expensive, both in first cost and maintenance, than the railway. Many districts winch are at present almost totally vidueless,from,the point of view of productivity could be opened up by a suitable type of vehicle operating from the nearest railheads.

The other chief desiderata which have been successfully met ari comparatively IOW first cost combined with an excellent degree of simplicity and accessibility, whilst adequate provision has been made in the arrangement of the semi-bogie to avoid any tendency for one pair of wheels to take an undue share of the work, either when climbing exceedinkly steep hills or when braking.

The maximum possible flexibility in the semi-bogie is attained by employing a pair of parallel semi-elliptic springs at each side, these being centrally fulcrumed on a rocker shaft which extends right across the frame and is mounted in large V-brackets bolted to the side members. Each a the two driving axles is provided with spring bearers , which are spherically mounted so that they can rock in any direction, and, in addition to this, they are permitted a certain degree of sideways movement, the spring ends are pinned to them in

• the usual manner.

One of the leading features of the new Morris is that the torque from each axle, whether this be due to the drive or braking, is conveyed to the chassis frame via adjustable and universally jointed connections and a cross-bearer. The points of attachment on the axles are on extension brackets bolted to the worm casings.

The axles of the semi-bogie are of practically standard construction—in fact, they are almost entirely based upon the rear axle of the Morris one-tonnerMid they are duplicates except that in the case of the first one the worm shaft is connected by a short shaft with Spicer joints to the driving worm of the second axle. Steel straps bolted to the frame side members limit the amount by which any bogie wheel can drop in relation to the frame, whilst thick rubber blocks mounted under the lower flanges of the side Members limit the upward travel and prevent hammer blows on the chassis.

It is notable that both the spring bearers on the axles and the universal joints on the torque members are equipped with loathes dust-excluding and oil-retaining bellows, thus enabling the vehicle to pass through dust and mud without detriment to these working parts.

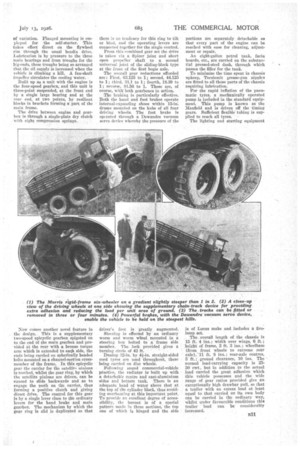

Before going fully into the details of the design, we must, however, refer particularly to another remarkable feature of the equipment. This consists of two sets of chain tracks of simple design and provided with adjustable connecting links by which each may be joined in a few moments. These tracks are mounted between the twin tyres of each rear wheel—au operation which occupies three to four minutes—thus forming a connection between the pair of driving wheels at each side. In this manner the vehicle is practically converted to a chain-track type giving a most effective grip upon the surface on which it is travelling; this grip being accentuated by the special form of the track plates, details of which can be seen in some of the illustrations.

When not in service, these tracks can easily be carried by brackets bolted to the rear portion of the body in such a manner that each track has One end supported at one side of the body, the track being earried right underneath the chassis frame and the other end secured to the corresponding bracket at the other side

• This six-wheeler has already proved its merits and has come through the most searching tests• With, flying colours. It has actually climbed a test hill of one in one—in other words—at an angle,of 45 degrees. As a result of this and other features, it is claimed that it Can meet the requirements of _road and cresS-conntry transport all over the world to the extent of .95 per cent., dud although

this Would appear' to -beextraordinary: claimi' yet the "tests' so far conducted would seem fully to justify it, and for this reason its 'sponsors refer to it as the " go anywhere" transport vehicle.

The semi-bogie is extremely flexitoEach wheel on each driving axle can be at least 6 ins, higher than the corre49po,nding wheel on that axle ; again, either of the rear axles can he more than 8 ins, above the other, and during such movements the frame remains in its normal position relative to the ground.

The power unit is a 15.9 h.p. type similar to that employed in the 25S0-cwt. chassis. It gives 18 b.h.p. at 1,000 r.p.m. and a torque of 95-ft.-lb.' The pistons are of aluminium alloy and the connecting rods are forged steel. A single casting is employed for the cylinder block and the upper half of the crankcase, whilst the camshaft operates against mushroom-headed tappets with fine %brew adjustment and is lubricated from the crankcase ; the cylinder-head casting is, of course, detachable. Spiral gears are employed for driving the camshaft, dynamo and magneto. The dynamo is a 12-volt machine, and this and the h.t. magneto are driven in tandem, being connected by a special coupling which gives an infinite range of variation. Flanged mounting is employed for the self-starter. This takes effect direct on the flywheel rim through the usual bendix drive. Lubrication is by pressure to the three main bearings and from troughs for the big-ends, these troughs being se arranged that the oil supply is increased when the vehicle is climbing a hill. A fan-shaft impeller circulates the cooling water.

Built up as a unit with the engine is the four-speed gearbox, and this unit is three-point suspended, at the front end by a single large bearing and at the rear end, at two points, by resilient blocks in brackets farming a part of the main frame.

The drive between engine and gearbox is through a single-plate dry clutch with eight compression springs., Now comes another novel feature in the design. This is a supplementary two-speed epicyclic gearbox spigoted on to the end of the main gearbox and provided at the rear with a bronze torque arm which is extended to each side, the ends being carried on spherically headed bolts mounted on a channel-section crossmember of the frame. In this epicyclic gear the carrier for the satellite ninions is toothed, whilst the gear ring, by which the satellite pinions are driven, can be caused to slide backwards and so to engage the teeth on the carrier, thus forming a positive clutch and giving direct drive. The control for this gear is by a single lever close to the ordinary levers for the hand. brake and main gearbox. The mechanism by which the gear ring is slid is duplicated so that there is no tendency for this ring to tilt or bind, and the operating levers are Connected together for the single control.

From this combined gear set the drive is taken via a Spicer joint and short open propeller shaft to a second universal joint of the sliding-block type at the front of the first bogie axle.

The overall gear reductions afforded are: First, 63.125 to 1; second, 44.125 to 1; third, 31.1 to 1; fourth, 18.39 to 1; reverse, 81.56 to 1. These are, of course, with both gearboxes in action.

The braking is particularly effective. Both the hand and foot brakes operate internal-expanding shoes within 154nT, drums mounted on the hubs of all four driving wheels. The foot brake is operated through a Dewandre vacuum servo device whereby the pressure of the driver's foot is greatly augmented.

Steering is effected by an Ordinary worm and worm* wheel mounted. in a steering box bolted to .a frame side member. The lockprovided gives a turning circle of 42 ft.

Dunlop :12-in, by e41-in. straight-sided cord tyres are used throughout, these being carried on disc wheels.

Following sound' commercial-vehicle practice, the radiator is built up with a detachable centre and east-aluminium sides and bottom tank. There is an adequate head of water above that at the top of the cylinder block,' thus avoiding overheating at this important, point. To:provide an excellent degree of accessibility, the bonnet is of a special pattern made in three sections, the top one of which is hinged and the side portions are separately detachable so that every part of the engine can be reached with ease for cleaning, adjustment or repair.

An eight-gallon petrol tank, facia boards, etc., are carried on the substantial pressed-steel dash, through which passes the filler for the tank.

To minimize the time spent in chassis upkeep, Teca!emit grease-gun nipples are fitted to all those parts of the chassis requiring lubrication.

For the rapid inflation of the pneumatic tyres, a mechanically operated pump is included in the standard equipment. This pump is known as the Maxfield and is driven off the timing gears. Sufficient flexible tubingis supplied to reach all tyres.

The lighting and starting equipment is of Lucas make and includes a fivelamp set.

The overall length of the chassis is 15 ft. 4 ins.; width over wings, 6 ft.; height oi frame, 2 ft. 3 ins.; wheelbase (from front wheels to extreme rear axle),'11 ft. 8 ins. ; rear-axle centres, 3 ft.; ground clearance, 10 ins. The normal load-carrying capacity is 2530 cwt., but in addition to the actual load carried the great adhesion which -this vehicle possesses and the wide range of gear ratios provided give an exceptionally high drawbar pull, so that a trailer with an excess load at least equal to that carried on its own body can be carried in the ordinary way, Avhilt under favourable conditions this trailer load can be considerably -increased.