The Wheel Question.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

In a previous number of this paper, under the title of " Wheel Inventiveness," there appeared a history of the motor wagon wheel, from the experimental types of the pioneer vehicles up to the present day. The subject proved too large to be dealt with exhaustively in the space available, and was therefore confined to those wheels which have a metal tyre in contact with the road surface. But for the motor delivery van, and the public service vehicle, a resilient tyre is a necessity, and, even on the heaviest steam lorry, a tyre of some substance other than metal can be used with advantage.

So far as rubber-tyred wheels are concerned, early attempts to use them on commercial vehicles were more or less of a failure, chiefly because it was not realised that rubber had a safe working load proportional to the section of the tyre. In those days rubber tyres were often loaded to a point beyond the limit of structural cohesion between the particles. The rubber was then unable to " give " further to inequalities of the road surface and, in effect, whilst still deadening noise, acted as a non-resilient tyre. Also, more engine power was required from lack of spring in the rubber as each part of the tyre came round, whilst the wheels dragged very badly. To get satisfactory results from rubber tyres, the following will be found a good working rule to find the size of tyre to be employed :—Take threefifths of the axle load in cwts. and extract the square root. The result will be the proper size of tyre to be employed, on each wheel on that axle, in inches. For axle weights of two tons and over, it is better to use twin tyres; to calculate the proper size of twin tyres, three-tenths of the axle weight in cwts. gives the square of the tyre size in inches According to this rule, sin. tyres are not suitable for axle loads above tscwt. ; kin. tyres will suit up to axle loads of zscwt., and sin. tyres for axle loads up to two tons. For all but very light delivery vans it is better to use twin tyres, that is to say two tyres, side by side, on the same wheel. It must not be forgotten that the cross sectional area is the determining factor, not the width of the tyre, and therefore two kin. tyres would be necessary to replace one 6in. tyre. For motor buses, weighing over six tons when fully loaded, sin, twin tyres are none too large, and, therefore, much of the excessive cost of tyre upkeep on many buses can be traced to using twin kin. tyres instead of twin sin. tyres. Another advantage of twin tyres which will appeal forcibly to the commercial user is that, in the event of one tyre coming off, the vehicle can be run home on the other tyre without injury to the wheel or mechanism, and with but slight reduction in speed. The rubber tyres are secured in a metal rim, with section to suit the particular make of tyre, and the majority of the makers are using ordinary artillery wheels with these tyres. The Leyland buses are fitted with the firm's well-known composite wheel, having a cast-steel centre and wooden felloes.

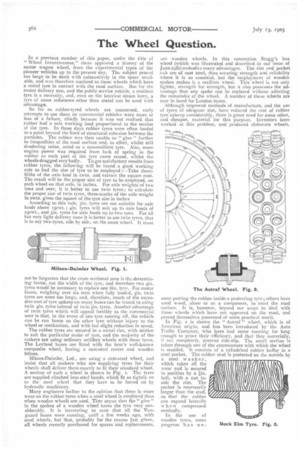

Milnes-Daimler, Ltd., are using a cast-steel wheel, and insist that all makers who are supplying tyres for their wheels shall deliver them exactly to fit their standard wheel. A section of such a wheel is shown in Fig. 1. The tyres are supplied clinched into steel bands, which fit so tightly on to the steel wheel that they have to be forced on by hydraulic machinery. Many engineers incline to the opinion that there is more wear on the rubber tyres when a steel wheel is employed than when wooden wheels are used. They argue that the " give" in the spokes of a wooden wheel saves the tyre very considerably. 'ft is interesting to note that all the Vanguard buses were running, until a few weeks ago, with steel wheels, but that, probably for the reason just given, all wheels recently purchased for spares and replacements,

are wooden wheels. In this connection Stagg's bus wheel (which was illustrated and described in our issue of June 29th) embodies many advantages. The rim and pocket mils are of cast steel, thus securing strength and reliability where it is so essential, but the employment of wooden spokes makes it a resilient wheel. This wheel is not only lighter, strength for strength, but it also possesses the advantage that any spoke can be replaced without affecting the remainder of the wheel. A number of these wheels are now in hand for London buses.

Although improved methods of manufacture, and the use of tyres of adequate size, have reduced the cost of rubber tyre upkeep considerably, there is great need for some other, and cheaper, material for this purpose. Inventors have worked at this problem, and produced elaborate wheels, some putting the rubber inside a protecting tyre; others have used wood, alone or as a component, to meet the road surface. It is, however, beyond our scope to deal with those wheels which have not appeared on the road, and proved themselves possessed of some practical merit.

In Fig_ 2 is shown the " Autraf " wheel, which is of American origin, and has been introduced by the Auto Traffic Company, who have had some running for long enough to prove their efficiency, and that they materially, if not completely, prevent side-slip. The small section is taken through one of the excrescences with which the wheel is studded. It consists of a cylindrical rubber buffer in a steel pocket. The rubber stud is protected on the outside by a steel washer, which takes all the wear and is secured in position by a

bolt, with a nut inside the rim. The pocket is necessarily larger than the stud, so that the rubber can expand laterally when compressed vertically.

In the use of wooden tyres, more progress has un the axle load, and therefore in the larger towns there will be found commercial motors with a six-ton tare weight, taking a paying load of eight tons, making a gross load of fourteen tons distributed equally over all four wheels. Naturally with such axle weights, rubber tyres did not last long, and wooden tyres have in most cases taken their place. The ‘yood that has proved most satisfactory is rock elm, grain on end, and it is held in the rim in the same manner as a rubber tyre. Fig. 3 shows a section through the tyre and rim, and the wheels are clearly shown on the Michigan Stove Company's wagon in our issue of May 4th. The tyres cost one-sixth of the price for rubber tyres, and last four times as long. Fig. 4 shows another type of wheel, designed by Prof. Hele-Shaw, so well known as an authority on motor construction, and it vill be noticed that the spokes are made of half-round spring steel, bent to U-shape. The ends are held between cast-steel plates, at the hub, and the centre part of each spoke beds in a groove in the cast-iron rim. There is thus a small amount of spring in the spokes, sufficient to take up the jar caused by inequalities in the road surface, and at the same time the design lends itself to the easy replacement of any faulty spoke. There is no doubt that the last word has not yet been said on the subject of motor bus wheels and tyres. All the motor bus companies are experimenting with various makes of tyres, but so far they do not seem to have tried the various forms of spring wheels that have been invented to meet their requirements, such as the " Empire," " Halle," " Starley," " Hele-Shaw," etc. Some of these wheels have been subjected to long and severe tests by the makers and are worthy of attention from those who have had trouble with present patterns.