BEDFORD KM

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

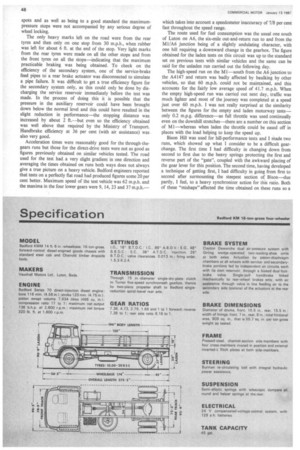

16-TON-GROSS FOUR-WHEELER

MANY operators have in the past considered it quite legitimate to buy medium-weight vehicles-8-tonners for example— and run them at the maximum legal gross weight of 14 tons even though the chassis were not necessarily designed for it. With the raising of the maximum gross to 16 tons for four-wheelers, only vehicles plated as being suitable for operation at the higher weight can take advantage of the extra 2 tons and when plating is extended at the end of this year it will not be possible to run new vehicles at even the old maximum of 14 tons unless they are designed for it and plated accordingly.

It is therefore logical that the trend for medium-weight vehicle makers to extend upwards into the maximum-gross field, started in 1964 by one manufacturer, should have been continued by Vauxhall Motors with the introduction of the Bedford KM at the 1966 Commercial Motor Show; a third maker is due to make the same move in a short time. As many operators will verify, mediumweight Bedfords have been operated satisfactorily at 14 tons gross in the past but to provide a model suitable for 16 tons the company has had to start virtually from scratch in going to 16 tons with the KM. Only the cab is retained from previous designs.

After carrying out a full road test of the KM I can say that Bedford engineers have done an excellent job. The test vehicle performed very well indeed, with good fuel consumption, acceleration and braking figures and handling was superb—thanks primarily to one of the best power-assisted steering layouts that I have ever come across. The only criticism I would make is of the gear change which, although an improvement over the TKs I have driven previously, proved hard to get used to, and I found difficulty in engaging the lower ratios.

The vehicle offered for test by Vauxhall had the shortest of the three wheelbases available for normal haulage work. In addition the KM range consists of tippers in three wheelbases, and two tractive units, both for 22 tons gross and in wheelbase lengths of 9 ft. 1 in.or 10ft.

The KM range was described in COMMERCIAL MOTOR on September 9 1966 and as already stated the design is new from front to back apart from the cab. The test chassis had the standard specification, which includes a direct-top gearbox and single-speed rear axle. On all the rigids an overdrive-top gearbox is available and a two-speed axle is obtainable on all KM models with two alternative sets of ratio.

The engine is the new Bedford Series 70 diesel which was developed for the KM and has a capacity of 466 cu. in. (7.634 litres). It produces a maximum net output of 136 b.h.p. at 2,800 r.p.m. and a maximum net torque of 320 lb. ft. at 1,600 r.p.m. The new Turner five-speed gearbox in the model has synchromesh on the upper four ratios and is mounted to the engine with the mainshaft and the layshaft on the same horizontal plane. Mounting the gearbox in this way enables a better line for the gearchange linkage to be obtained.

The gearbox in the test vehicle had a bottom ratio of 7.36 to 1 but the optional box with an overdrive of 0.86 to 1 has a 6.17 to 1 bottom ratio. It is probable that an operator specifying an overdrive box would specify also a two-speed axle to retain the hillclimbing ability with the standard unit; as against the 6.17 to 1 ratio in the standard axle, ratios of 6.50/8.87 and 5.57/7.68 can be obtained in the optional Eaton axle. The design of the Bedford axle is unusual in that the differential-casing face is at an angle to the vertical, with an angled input shaft to the driving head, The main reason for this is to give improved strength to the drive casing; the Eaton axle is of conventional design.

A feature of the KM design is the braking system. The front brakes are larger than is usual, being 7 in. wide by 15.5 in. diameter, compared with 8 in. by 15.5 in. at the rear and the secondary braking system provided is a complete duplication of the service brakes. The brakes themselves are Girling wedgeoperated two-leading-shoe units whilst the actuators at all wheels are Clayton Dewandre piston/diaphragm units with the diaphragms used for the service brakes and the pistons for the secondary system. Air assistance to the application of the handbrake is provided by the linkage being connected to the actuator pistons at the rear axle and, as the handbrake is applied, air is fed to the rear part of the secondary-brake system.

This is the fourth test of a 16-ton-gross four-wheeler that has been carried out by COMMERCIAL MOTOR and once again the need for manufacturers to change their thinking on plating of vehicles was illustrated. It is usual to plate a two-axle machine for 6 tons front axle and 10 tons rear axle (as with the KM). But whilst the latter figure has to be included because this is the maximum legal axle load, front axles should be designed and plated for a little higher figure to give some leeway in loading. It is absolutely unreasonable to expect a vehicle to be loaded so that 6 tons on the front axle and 10 tons on the driving axle are not exceeded while working to a 16-ton-gross figure and any extra over the plated figure is illegal. The Bedford KM has a front axle rated for 6.5 tons and this figure should be included in the plate. As with the previous 16-ton-gross machines tested, the front axle was carrying over 6 tons even with a well-placed load and even with no one in the cab the 6 tons was exceeded by 2 cwt. All the ladenperformance tests were carried out at the weights quoted in the specification panel and it will be seen that the total weight of concrete blocks carried was 10 tons 18 cwt.

Brake tests were the first to be carried out and the road was dry except for slightly damp patches where the early-morning frost had not cleared. The stopping-distance figures quoted in the tables were obtained on sections of the road where there were no damp spots and as well as being to a good standard the maximumpressure stops were not accompanied by any serious degree of wheel locking.

The only heavy marks left on the road were from the rear tyres and then only on one stop from 30 m.p.h., when rubber was left for about 6 ft. at the end of the stop. Very light marks from the rear tyres were made on all the other stops and from the front tyres on all the stops—indicating that the maximum practicable braking was being obtained. To check on the efficiency of the secondary system, one of the service-brake feed pipes to a rear brake actuator was disconnected to simulate a pipe failure. It was difficult to get a true efficiency figure for the secondary system only, as this could only be done by discharging the service reservoir immediately before the test was made. In the process of doing this it is possible that the pressure in the auxiliary reservoir could have been brought down below the normal level and this could have resulted in the slight reduction in performance—the stopping distance was increased by about 2 ft.—but even so the efficiency obtained was well above that required by the Ministry of Transport. Handbrake efficiency at 36 per cent (with air assistance) was also very good.

Acceleration times were reasonably good for the through-thegears runs but those for the direct-drive tests were not as good as figures previously obtained on similar vehicles tested. The road used for the test had a very slight gradient in one direction and averaging the times obtained on runs both ways does not always give a true picture on a heavy vehicle. Bedford engineers reported that tests on a perfectly flat road had produced figures some 20 per cent better. Maximum speed of the test vehicle was 62 m.p.h. and the maxima in the four lower gears were 9, 14, 23 and 37 m.p.h.— which takes into account a speedometer inaccuracy of 7/8 per cent fast throughout the speed range.

The route used for fuel consumption was the usual one south of Luton on A6, the six-mile out-and-return run to and from the Ml/A6 junction being of a slightly undulating character, with one hill requiring a downward change in the gearbox. The figure obtained for the laden tests on this circuit was up to the standard set on previous tests with similar vehicles and the same can be said for the unladen run carried out the following day.

The high-speed run on the Ml—south from the A6 junction to the A4147 and return was badly affected by baulking by other vehicles, so that 60 m.p.h. could not be maintained, and this accounts for the fairly low average speed of 41.7 m.p.h. When the empty high-speed run was carried out next day, traffic was much lighter and most of the journey was completed at a speed just over 60 m.p.h. I was not really surprised at the similarity between the figures for the empty and laden motorway tests— only 0.2 m.p.g. difference—as full throttle was used continually even on the downhill stretches—there are a number on this section of M1—whereas when laden the throttle could be eased off in places with the load helping to keep the speed up.

Bison Hill was used for hill-performance tests and I made two runs, which showed up what I consider to be a difficult gearchange. The first time I had difficulty in changing down from second to first due to the heavy springs protecting the first and reverse part of the "gate", coupled with the awkward placing of the gear lever for this position. The second time, having developed a technique of getting first, I had difficulty in going from first to second after surmounting the steepest section of Bison—due partly, I feel, to a heavy synchronizer action for this ratio. Both of these "mishaps" affected the time obtained on these runs so a further trip was made with Stan Rowe of Bedford driving. He completed the 0.75-mile run up Bison without any hold-up due to faulty gear changing, but I must say in my defence that the gear lever did not "fall in". The time taken for the run was 4 mm. 243 sec. with 1 mm. 26.8 sec. spent in first gear, the lowest used, and the minimum speed was 5 m.p.h. As the KM cooling system incorporates a header tank, no direct measurement of the rise in coolant temperature could be made, but the dash-mounted temperature gauge did not rise above the half way mark during the climb.

After my first attempt at climbing Bison I made a run down the hill—which has an average gradient of 1 in 10.5—to assess brake-fade characteristics. As usual, most of the run was made in neutral with the brakes applied to restrict the speed to 20 m.p.h., and near the bottom of the hill top gear was engaged and full throttle applied—with the brakes still in use---to keep the road speed at the same figure. After a run lasting 2 min. 57 sec., with 40.4 sec. spent driving against the brakes, a Tapley-meter reading of 51 per cent from 20 m.p.h. was obtained for a maximum-pressure stop. This compared with 76 per cent which was obtained from 20 m.p.h. and 30 m.p.h. on the cold-drum tests earlier and indicates that whilst this severe test had produced some fade it had not brought efficiency below an acceptable figure.

A final trip up Bison was made to assess handbrake-holding ability and to complete stop-and-restart tests. These were carried out with the vehicle both facing up and facing down the hill on the steepest section, which has a gradient of 1 in 6.5. In both positions the handbrake held the vehicle comfortably even with the air pressure discharged from the brake system by repeated applications of the brake pedal. Easy restarts were made in first gear when facing up the hill and in reverse when facing down.

I found the Bedford KM a most enjoyable vehicle to drive, with adequate power for the type of terrain met with in the Bedford area, responsive brakes, a high degree of driver comfort, light and wellplaced controls and, probably most of all, because of the excellent steering. The new Burman steering box developed for the KM has integral power assistance and is a very well designed unit. Steering the KM is no harder than driving a medium-sized car and yet there is no vagueness or tendency to over-correct in either the laden or unladen condition. Visibility and the general features of the cab on the KM—as users of the Bedford TK will know, since it is virtually the same unit—are very good. Differences on the KM are that a Bostrom-sprung driver's seat, a second mirror on the offside (giving a wide spread) and windscreen washers are standard. All of them are worthwhile improvements to the specification. The use of 10.00-20 tyres in conjunction with the standard TK cab design results in a slight increase in the first-step height, but access is still easy, as in the unladen condition this is only 2 ft. 4 in. and the floor of the cab is 3 ft. 6 in. from the ground.

Maintenance facilities provided on the KM arc similar to those on the TK except that the work of greasing is reduced and there are only five points requiring this attention. Some people would have liked to see the KM cab tilt to improve accessibility to the engine, but routine maintenance and attention to the power unit is not hampered by difficulty of access in the design. Panels at the rear of the cab hinge upwards as on the TK, and in addition the rear portions of the front wings hinge downwards to allow a fitter to get close to the engine. The only value that a change to a tilt cab would have is in engine replacement, which is not a frequent job.

The basic price of the Bedford KM chassis/cab as tested is £2,335, which represents very good value for a vehicle of this standard of design and performance. I would like to try the chassis fitted with the overdrive gearbox and two-speed axle options. There is no extra charge for the alternative gearbox but the axle option costs £160. I am sure that expenditure on this item would give an improvement in fuel consumption and represent a good investment, and I dO not think there would be any reduction in performance.