Watsons (Carriers Limited

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

"WE LIKE to keep things simple," Mr. J. H. Wade, joint managing director of Watsons (Carriers) Ltd., parcels carriers, told me: "This is the easiest way of ensuring that everybody knows what he is to do."

The company was founded in 1922 by the father of Mr. K. C. Watson, the present joint managing director with Mr. Wade. It was formed into a limited company in 1958 and was taken over by the Tayforth group of companies in 1963. In 1965 the Tayforth group became part of the Transport Holding Company. Following the Transport Act 1968, the National Freight Corporation grouped its parcels and sundries companies into British Express Carriers Ltd. Watsons (Carriers) Ltd. is one of several companies controlled by the Parcels Division of BEC.

On my recent visit to Watsons I learned that management of the company is still very much in the hands of the original partners (except Mr. Watson, snr) who are now directors—Mr. Wade, Mr. Watson and Mr. J. G. Cornall—there being very little interference from the top management of BEC; a sign that things are going well, I was told. The directors share an office and so, they added, live in a world of full-time management meetings. This triumvirate set-up seems to be good for both the company (turnover has been boosted from £.100,000 in 1963 to a 1969 figure which just broke half a million pounds) and for the staff—just over 200—with whom I was assured relations are very good.

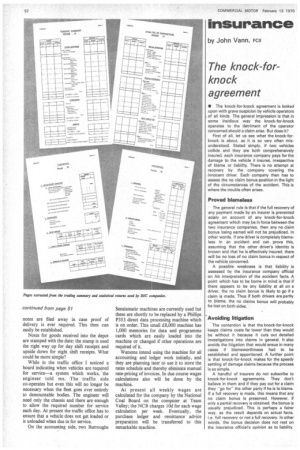

The management work to a set budget and prepare four-weekly trading summaries and statistical returns for the senior management. Although these returns could hardly be called simple the remainder of the operation appeared to be, so logical and straightforward system is used and nowhere did I find any built-in complications; something which Mr. Wade felt was too prevalent in many organizations. The new British Express Carriers management is reviewing its requirements and this will lead to a greater simplification in the preparation of the control information.

Dernountables

The company operates 92 vehicles; all except one—an AEC—are Bedfords. Five of the fleet are tractive units used with large-capacity-van trailers to deliver big stock orders out of the warehouse. The remainder are 8+-ton g.v.w. box vans of approximately 900 Cu. ft. capacity. A 4/5-ton payload can be carried on these vehicles. Vehicles are being used with demountable bodies as part of a plan to speed the turnround of vehicles and to provide a more even distribution of loading operations; it also helps considerably on the maintenance side. At the time of my visit 23 of the Bedfords operated on this system and 10 new chassis delivered while I was there are also to be fitted similarly. In fact, all future vehicles will follow this pattern. The demountable system used is a new one manufactured by Northern Transport Engineering Ltd.

The 11-acre Spennymoor depot has only been occupied for four years, the company having moved there from Bishop Auckland, four miles away. With a prime position at the entrance to a large industrial estate, near a motorway, and in a de-restricted speed area the company feels it is ideally situated; 80 per cent of traffic is delivered within a 25-mile radius and this almost completely covers the built-up industrial area of the North East.

The area covered also corresponds very closely with the Tyne-Tees television area, so Watsons benefit from increased traffic in the area following manufacturers' TV advertising and product-testing campaigns.

Besides daily deliveries in the area mentioned, a container is loaded and despatched daily to Scottish Parcel Carriers Ltd. in Glasgow on the Freightliner network, a vehicle runs daily to Bridges Transport Ltd., Preston, and a trunk vehicle arrives daily froin Hansons of Leeds. This is an important linking together of four BEC companies. Every other day a vehicle delivers farther north in the Berwickon-Tweed area.

Nine vehicles operate exclusively on contract to Boots the chemists, delivering on a timetable schedule—to within 10 minutes—to Boots shops in the area. Packages between the shops and the Nottingham head office, including urgent prescription orders, are also carried on these vehicles.

The company also has a warehousing operation. Many household names feature among the traffics stored Which vary from foodstuffs, which constitute a large part of the stocks, chemicals, carpets, and paint--stored in a special heated section--and even refrigerators. The warehouse covers an area of 88,000 sq. ft.

The parcels loading bank covers approximately 30,000 sq. ft. Loading or unloading can take place from either side and the area is divided into sections corresponding with delivery routes. A new innovation to speed movement of orders within the loading bank area is an Acrow sunken-rail truck guidance system. A truck can circuit the loading bay in eight minutes and this will, when it is fully operational, save a great deal of walking by staff.

All consignments handled by Wat sons 600,000 in 1969—are turned round,

in and out, within 24 hours. Any traffic which a driver has not managed to deliver one day is given priority for delivery the next. When he hands his documents in at night, those for the undelivered items are stamped "priority" and put in the rack for the next day. In this way no consignment can become lost.

Great care is taken to ensure that a track is kept of all consignments; in fact I was told that any item which the company is currently handling can be pinpointed to its exact location at any time, because all loads inwards and outwards are double-checked off and on vehicles. Items do not go astray, because once received the checking system prevents them going out again except on the correct vehicle. When inwards bulk loads are received for redistribution a discrepancy sheet is prepared with details of any differences between the consignment note arid what is received. If no discrepancies are found a sheet is still sent to the customer showing a nil return.

Summary sheets

Load summary sheets are prepared daily in the traffic office on which details of all consignments on a particular load are entered. A driver's record summary is also used which is cross referenced to the load summary sheet. On this, against the driver's

name, is enterer.F his vehicle number, the number of consignment notes he has for his load, the number of deliveries and collections he has to make and the number of discrepancies.

Discrepancies which appear on this summary are transferred to a daily discrepancy sheet in the traffic office ready for investigation. I was surprised to see how few entries appeared on these daily sheets considering the number of consignments handled, and I noticed that entries were quickly cancelled indicating that very little investigation was needed to find the answer.

A special load summary sheet for Freightliner loads is prepared and an independent summary sheet is also used so that an absolute check is kept on these loads. When the daily Freightliner container number is known this is chalked on a board so that all traffic office staff know its number.

When drivers make a delivery, they obtain a signature and also mark their own name and the date on the delivery note so that a check can always be made to see who delivered any consignment. On return to the depot drivers hand in all their notes and documents, These are pinned together and all are carefully checked the next day by office staff. After checking all the delivery

notes are filed away in case proof of delivery is ever required. This then can easily be established.

Notes for goods received into the depot are stamped with the date: the stamp is used the right way up for day shift receipts and upside down for night shift receipts. What could be more simple?

While in the traffic office I noticed a board indicating when vehicles are required for service—a system which works, the engineer told me. The traffic side co-operates but even this will no longer be necessary when the fleet goes over entirely to demountable bodies. The engineer will need only the chassis and there are enough to allow the required number for service each day. At present the traffic office has to ensure that a vehicle does not get loaded or is unloaded when due in for service.

On the accounting side, two Burroughs Sensismatic machines are currently used but these are shortly to be replaced by a Phillips P353 direct data processing machine which is on order. This small £8,000 machine has 1,000 memories for data and programme cards which are easily loaded into the machine or changed if other operations are required of it.

Watsons intend using the machine for all accounting and ledger work initially, and they are planning later to use it to store the rates schedule and thereby eliminate manual rate-pricing of invoices. In due course wages calculations also will be done by the machine.

At present all weekly wages are calculated for the company by the National Coal Board on the computer at Team Valley; the NCB charges 10d for each wage calculation per week. Eventually, the purchase ledger and remittance advice preparation will be transferred to this remarkable machine.