Coaling Valves Internally by Salt.

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

ONE of the difficulties eouf routing the designer of engines of high efficiency and of correspondingly high compression is the adequate cooling of the valves. There is not a great amount of metal in the ordinary valve stem, and the heat is usually concentrated at the head. Adequate water-jacketing of the valve seats helps considerably, chiefly in avoiding excessive distortion of the seat. It must he remembered, however, that the valve is off its scat for a considerable portion of the working cycle.

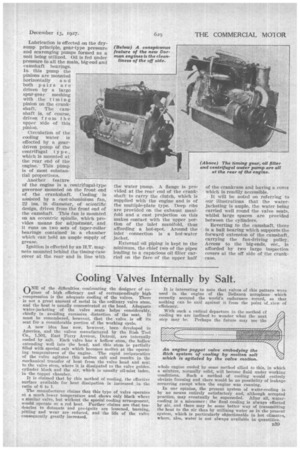

A new idea has now, however, been developed in America, and the valves manufactured by the Rich Tool Co., 1,501, East Ferry Avenue, Detroit, are internally cooled by salt. Each valve has a hollow stem, the hollow extending well into the head, and this stein is partially filled with special salt which becomes molten at the operating temperatures of the engine. The rapid reciprocation of the valve agitates this molten salt and results in the mechanical transfer of heat from the valve head and seat to the valve stem, where it is dissipated to the valve guides. cylinder block and the air, which is usually oil-mist laden, in the tappet chamber.

It is claimed that by this method of cooling, the effective surface available for heat dissipation is increased in the ratio of 6 to 1.

The manufacturer claims that this type of valve operates at a much lower temperature and shows only black where a similar valve, but without the special cooling arrangement, would operate at a red heat. Further claims are that tendencies to detonate and pre-ignite are lessened, burning, pitting and wear are reduced, and the life of the valve consequently greatly increased.

It is interesting to note that valves of this pattern were used in the engine of the Dellanca aeroplane which recently secured the world's endurance record, so that nothing can be said against it from the point of view of efficiency.

With such a radical departure in the method of cooling we are inclined to wonder what the next step may be. Perhaps the future may See the

whole engine cooled by some method allied to this, in which a mixture, normally solid, will become fluid under working conditions. Such a method of cooling would entirely obviate freezing and there would be no possibility of leakage occurring except when the engine was running.

In our opinion, the present system of water-cooling is by no means entirely satisfactory and, although accepted practice, may eventually be superseded. After all, watercooling is a misnomer; the final cooling is always -effected. by air, and there may be some better way of transmitting the heat to the air than by utilizing water as in the present system, which is particularly ohjecticinable in hot climates, where, also, water is not always available in quantities.