Suspension 8

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

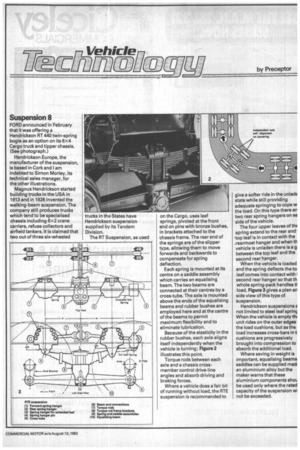

FORD announced in February that it was offering a Hendrickson RT 440 twin-spring bogie as an option on its 6x4 Cargo truck and tipper chassis. (See photograph.) Hendrickson Europe, the manufacturer of the suspension, is based in Cork and I am indebted to Simon Morley, its technical sales manager, for the other illustrations.

Magnus Hendrickson started building trucks in the USA in 1913 and in 1926 invented the walking-beam suspension. The company still produces trucks which tend to be specialised chassis including 6x2 crane carriers, refuse collectors and airfield tankers. It is claimed that two out of three six-wheeled

trucks in the States have Hendrickson suspension supplied by its Tandem Division.

The RT Suspension, as used on the Cargo, uses leaf springs, pivoted at the front end on pins with bronze bushes, in brackets attached to the chassis frame. The rear end of the springs are of the slipper type, allowing them to move forwards and backwards to compensate for spring deflection.

Each spring is mounted at its centre on a saddle assembly which carries an equalising beam. The two beams are connected at their centres by a cross-tube. The axle is mounted above the ends of the equalising beams and rubber bushes are employed here and at the centre of the beams to permit maximum flexibility and to eliminate lubrication.

Because of the elasticity in the rubber bushes, each axle aligns itself independently when the .vehicle is turning; Figure 2 illustrates this point.

Torque rods between each axle and a chassis crossmember control drive-line angles and absorb driving and braking forces.

Where a vehicle does a fair bit of running without load, the RTE suspension is recommended to give a softer ride in the unladc state while still providing adequate springing to cope w the load. On this type there an two rear spring hangers on ea side of the vehicle.

The four upper leaves of th( spring extend to the rear and 'top leaf is in contact with the ..rearmost hanger and when th vehicle is unladen there is a g between the top leaf and the second rear hanger.

When the vehicle is loaded and the spring deflects the to leaf comes into contact with second rear hanger so that th whole spring-pack handles ti load. Figure 3 gives a plan an side view of this type of suspension.

Hendrickson suspensions s not limited to steel leaf sprinc When the vehicle is empty thi unit rides on the outer edges the load cushions, but as the load increases cross-bars in t cushions are progressively brought into compression to absorb the additional load.

Where saving in weight is important, equalising beams saddles can be supplied mad, an aluminium alloy but the maker warns that these aluminium components shoi be used only where the rated capacity of the suspension wi not be exceeded.