Hydrostatics for low-built chassis

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

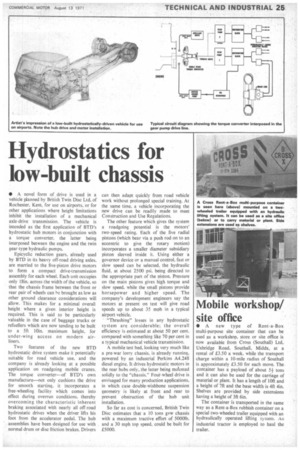

• A novel form of drive is used in a vehicle planned by British Twin Disc Ltd, of Rochester. Kent, for use on airports. or for other applications where height limitations inhibit the installation of a mechanical axle-drive transmission. The vehicle is intended as the first application of BTD's hydrostatic hub motors in conjunction with a torque converter, the latter being interposed between the engine and the twin gear-type hydraulic pumps.

Epicyclic reduction gears, already used by BTD in its heavy off-road driving axles, are married to the five-piston drive motors to form a compact drive-transmission assembly for each wheel. Each unit occupies only 18in. across the width of the vehicle, so that the chassis frame between the front or rear pair of wheels can he brought as low as other ground clearance considerations will allow. This makes for a minimal overall height where a given interior height is required. This is said to be particularly valuable in the case of baggage trucks or refuellers which are now tending to be built to a 5ft 10in, maximum height. for under-wing access on modern airliners.

Two features of the new BTD hydrostatic drive system make it potentially suitable for road vehicle use. and the company is already looking at a possible application on roadgoing mobile cranes. The torque converter—of BTD's own manufacture—not only cushions the drive for smooth starting. it incorporates a free-wheeling facility which comes into effect during overrun conditions. thereby overcoming the characteristic inherent braking associated with nearly all off-road hydrostatic drives when the driver lifts his foot from the accelerator pedal. The hub assemblies have been designed for use with normal drum or disc friction brakes. Drivers

can then adapt quickly from road vehicle work without prolonged special training. At the same time, a vehicle incorporating the new drive can be readily made to meet Construction and Use Regulations.

The other feature which gives the system a roadgoing potential is the motors' two-speed rating. Each of the five radial pistons (which bear via a push rod on to an eccentric to give the rotary motion) incorporates a smaller diameter subsidiary piston sleeved inside it. Using either a governor device or a manual control, fast or slow speed can be selected. the hydraulic fluid, at about 2500 psi, being directed to the appropriate part of the piston. Pressure on the main pistons gives high torque and slow speed. while the small pistons provide horsepower and higher speed. The company's development engineers say the motors at present on test will give road speeds up to about 35 mph in a typical airport vehicle.

"Thrashing" losses in any hydrostatic system are .con siderable; the overall efficiency is estimated at about 50 per cent. compared with something like 70 per cent in a typical mechanical vehicle transmission.

A mobile test bed, looking very much like a pre-war lorry chassis. is already running. powered by an industrial Perkins A4.248 diesel engine. It drives hydrostatic motors in the rear hubs only, the latter being molinted solidly to the "chassis." Four-wheel drive is envisaged for many production applications. in which case double-wishbone suspension geometry is likely at front and rear to prevent obstruction of the hub unit installation.

So far as cost is concerned, British Twin Disc estimates that a 10 tons gvw chassis with a maximum tractive effort of 50001b. and a 30 mph top speed, could be built for £5000.