Mack Building 7-torm€ Britain

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon

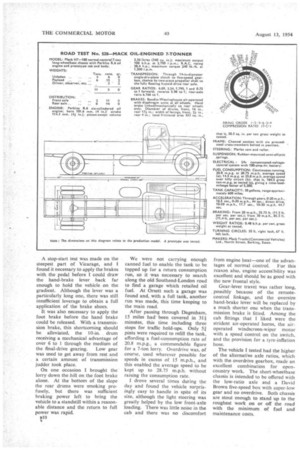

ALTHOUGH Mack Trucks (Britain?, Ltd., have been sole concessionnaires in this country for the Mack Motor Truck Corporation, of New York, for several years, no new vehicles of that make have been seen on British roads since the end of the var. The principal reason is that the import duty and freight charges on even a medium-weight lorry coming Into Great Britain from the U.S.A. exceed £3,000, or twice the value of the vehicle.

In addition, there is the difficulty of obtaining import licences owing to the restriction of dollar expenditure.

In order to make American-type trucks available to a far wider market at a reasonable price, Mr. Derek Mack has, through one of his companies, commenced production at Barking of a range of 7-ton trucks.

These vehiclesa.re British in design and manufacture, and where proprietary components have been used, all are standard units marketed by British manufacturers. A prototype oil-engined lorry has been running for many months, and I have tested it. It differs little from the production models and is tough and economical. It is built for fast, longdistance hauls, and is particularly suitable for use overseas, where the 20 m.p.h. speed limit does not apply.

Wheelbases of 16 ft. and 13 ft. 6 in. are available, the tatter being suitable for tippers. Leftor righthand drive may be specified, and there is a choice of two types of gearbox and two rear-axle ratios. The Hg power unit for all models is the Perkins R.6, which delivers 108 b.h.p. at its governed speed of 2,700 r.p.m. and develops 240 lb.-ft. torque at 1,700 r.p.m.

A David -Brown DB.0450D gearbox was fitted to the vehicle tested, this being a five-speed box with, a 0.75 to I overdrive top ratio. In order to take the gear lever well forward in the cab, an in-line remotecontrol mechanism is provided for gear changing.

The gearbox is bolted in unit construction with the engine and the whole assembly is mounted in the chassis frame at four points. The front sandwich rubbers are arranged in compression and shear, whilst the rear mounting consists of twin rubbers in shear attached to both sides of the clutch housing.

The two-piece propeller shaft has a Layrub coupling at the rear axle and Hardy-Spicer needle-roller bear ings at the other joints. On the production models a 10-in, diameter band type of transmission handbrake will be incorporated at the centre bearing, but on the prototype a conventional system of linkage I the rear brake drums was fitted.

Rear-axle ratios of 6.166 and 6.E to 1 are specified for the range, th final drive having hypoid gearini The axle casing is a fabricated ste. pressing of banjo formation.

Suspension at both axles consis of semi-elliptic springs, but th method of mounting these on th frame is unusual, in that no pins al employed. The spring ends are tx formed into eyes and are left fit with shallow U-shaped pressing riveted to the upper and lower face of the main leaves. Large dumbbel shaped rubbers are folded over th leaves at each end, and these fit int the spring anchor brackets. Th brackets are split along a horizonta axis and when clamped togethe with bolts, squeeze the rubbers o to the main leaves, thus holdin them securely in position.

At the rear of each leaf the rubber allow slight movement to cater fo spring deflection. No maintenanc. is required with this system, whicl has been used by the American corn pany for many years, and MI mounting is unaffected by dirt an moisture.

The depth of the frame sidi members is 9 in. throughout thei length, apart from where the lowe flange tapers upwards slightly abovi the front axle. Flange width is 3, in., and f-in.-thick steel pressing: are used for all frame components There are six bolted cross-members the spring brackets also are securec in this way.

Air-pressure braking is standar( on all models, with diaphragm unit: at the wheels. Clayton Dewandrt equipment will be installed on pro. duction chassis, but the vehicle I borrowed had Bendix-Westinghouse brake gear. This was of similat capacity to the British equipment and gave representative figures during the test. The Benclix-Westinghouge compressor required little adaptation for fitting to the Perkins engine.

Manes Type 611 cam-and-roller steering gear is used in conjunction with a 20-in.-diameter wheel. C.A.V. equipment is to be standardized for all electrical parts, and the system is 24v.

The test vehicle had a shorter wheelbase than subsequent models will have, being only 15 ft. between axle centres, and when loaded with tons 15i cwt, of bricks, the rearxle loading was 14 cwt. above the ecomrnended figure for the 9.00 by 0-in. 12-ply tyres with which the 4ack was fitted. Besides having an icreased wheelbase, later models till have the cab and engine mounted in. farther forward, and this should esult in a more even distribution of might.

When loaded and with driver and bserver aboard, the gross vehicle /eight was 11+ tons; of which the ,ak body accounted for 22 cwt. This

■ ody was removed from a previous how exhibit and will not be put into roduction. An alloy body which /mild weigh approximately 9 cwt., ; recommended for the chassis.

Cab, front Wings, bonnet and adiator shell were also of an experiaental nature and are to be replaced iy components of a more modern tyle which will increase the cab vidth by 4' in. With a bench seat here will be ample room for two iassengers in addition to the driver. Having collected the Mack from he Barking works, with the company epresentative driving, we set off °wards Southend for braking and .cceleration tests. I had always magined that Essex was a relatively lat county, but we had covered many rifles before I finally found a stretch )f road level enough for the shortfistance trials.

Even .so, it was impossible to conluct acceleration tests up to 40 m.p.h. )ecause of the lack of level ground. Iowever, using second, third and • ourth gears, 20 tri.p,h. was reached n 18.5 sec. from a standstill and 30 n.p.h. in 44.0 sec. under similar :onditions.

Top gear, being an overdrive, :mild not be used for the 10-20 n.p.h. and 10-30 m.p.h. tests, but vith fourth gear engaged 17.7 sec. and 44,7 sec. were required to attain 20 m.p.h. and 30 m.p.h. respectively. The R.6 pulled away from 10 m.p.h. with only a little excess vibration and the transmission took up the drive smoothly.

The braking system included connections for trailer operation, this being optional equipment on production models, and because of the relay valve in the air line, braking figures were increased by the delay. Brake reaction was proportional to pedal movement, and only light pedal pressure was necessary to secure full application of the brakes.

The stopping distances were 35,75 ft. from 20 m.p.h. and 85.5 ft. from 30 m.p.h. A further reason for these distances may be found in the light front-axle loading of just over 24 tons. The front wheels did not lock, however, and there was no tendency towards skidding.

At Romford the fuel tank was filled to overflowing in preparation for a fuel-consumption run, this being made for several miles along the Southend arterial road beferc turning off for South Benfleet. My choice of route was unfortunate, because having left the main road we encountered some very narrow lanes, sharp gradients and traffic delays.

After 14.5 miles, a gallon of fuel had been used, a not-too-disappointing figure in view of the fact that this is essentially a long-distance vehicle which thrives on continuous use of its overdrive.

North of South Benfleet lies Vicarage Hill, with an average gradient of 1 in .10 and a section of

1 in 8. I took the Mack to the bottom of this climb and checked the radiator top-tank temperature for normal value: This was found to be 135° F., the ambient temperature being 65° F.

Second gear was used for the ascent all the way, third gear being too high for the power available. At the end of this run the radiator • temperature had risers by 15° F.,

which indicates an ample latitude in the cooling system for working in hot climates. A second climb produced a further rise of only 5°F. and during this attempt it was possible to make brief use of third gear by taking a longer run at the hill. • A stop-start test was made on the steepest part of Vicarage, and I found it necessary to apply the brakes with the pedal before I could draw the hand-brake lever back far enough to hold the vehicle on the gradient. Although the lever was a particularly long one, there was still insufficient leverage to obtain a full application of the brake shoes.

It was also necessary to apply the foot brake before the hand brake could be released. With a transmission brake, this shortcoming should be alleviated, the 10-in, drum receiving a mechanical advantage of over 6 to 1 through the medium of the final-drive gearing. Low gear was used to get away from rest and a certain amount of transmission judder took place.

On one occasion I •brought the lorry down the hill on the foot brake alone. At the bottom of the slope the rear drums were smoking profusely, but there was sufficient braking power left to bring the vehicle to a standstill within a reasonable distance and the return to full power was rapid.

We were not carrying enough canned fuel to enable the tank to be topped up for a return consumption run, so it was necessary to search along the old Southend-London road to find a garage which retailed oil fuel. At Orsett such a garage was found and, with a full tank, another run was made, this time keeping to the main road.

After passing through Dagenham, 15 miles had been covered in 311 minutes, this time including three stops for traffic hold-ups. Only 52 pints were required to refill the tank, affording a fuel-consumption rate of 20.8 m.p.g., a commendable figure for a 7-ton lorry. Overdrive was, of course, used wherever possible for speeds in excess of 15 m.p.h., and this enabled the average speed to be kept up to 28.75 m.p.h. without raising the consumption rate.

I drove several times during the day and found the vehicle surprisingly easy to handle in spite of its size, although the light steering was greatly helped by the low front-axle loading. There was little noise in the cab and there was no discomfort

from engine heat—one of the advantages of normal control. For this reason also, engine accessibility was excellent and should be as good with the new frontal style.

Gear-lever travel was I Either long, . possibly because of the remotecontrol linkage, and the oversize hand-brake lever will be replaced by a much shorter one when the transmission brake is fitted. Among the cab fittings that I liked were the strident air-operated horns, the airoperated windscreen-wiper motor with a speed control on the switch. and the provision for a tyre-inflation hose.

The vehicle I tested had the higher of the alternative axle ratios, which with the overdrive gearbox, made an excellent combination for opencountry work. The short-wheelbase chassis is intended to be offered with the low-ratio axle and a David Brown five-speed box with super-low gear and no overdrive. Both chassis are stout enough to stand up to the roughest work on or off the road with the minimum of fuel and maintenance costs.