in the Sand and Gravel Business

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

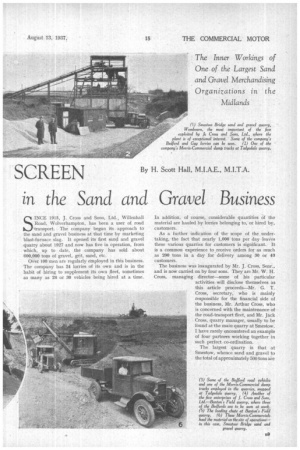

The inner Workings of One of the Largest Sand and Gravel Merchandising Organizations in the Midlands

SINCE 1915, J. Cross and Sons, Ltd., Willenhall Road, Wolverhampton, has been a user of road transport. The company began its approach to the sand and gravel business at that time by marketing blast-furnace slag. it opened its first sand and gravel quarry about 1927 and now has five in operation, from which, up to date, the company has sold about 600,000 tons of gravel, grit, sand, etc.

Over 100 men are regularly employed in this business. The company has 24 lorries of its own and is in the habit of hiring to supplement its own fleet, sometimes as many as 23 or 30 vehicles being hired at a time. In addition, of course, considerable quantities Of the material are hauled by lorries belonging to, or hired by, customers.

As a further indication of the scope of the undertaking, the fact that nearly 1,000 tons per day leaves these various quarries for customers is significant. It is a common experience to .receive orders for as much as 200 tons in a day •for delivery among 30 or 40 customers.

The business was inaugurated by Mr. J. Cross, Senn. and is now carried on by four sons. They are Mr. W. H. Cross, managing director—some of his particular activities will disclose themselves as this article proceeds—Mr. G. T. Cross, secretary, who is mainly responsible for the financial side of the business, Mr. Arthur Cross, who is concerned with the maintenance of the road-transport fleet, and Mr. Jack Cross, quarry manager, usually to be found at the main quarry at Smestow. I have rarely encountered an example of four partners working together in such perfect co-ordination.

The largest quarry is that at Smestow, whence sand and gravel to the total of approximately 500 tons are delivered on most days. This quarry is, perhaps, what might be termed the show place. It is in the centre of a plot of ground extending over 140 acres. It is equipped with plant designed and erected by the managing director, Mr. W. H. Cross, embodying features which he considers to be essential to the efficient and economic operation of a sand and gravel quarry.

The plant is designed so that 15 grades of material are automatically obtained in one operation from whatever is put into it. During that continuous operation, the material is untouched by hand.

The 15 grades comprise nine sizes of crushed gravel, one of uncrushed gravel, four grades of washed sand and one of washed grit. The sand, and grit are equivalent to five grades of sand.

Working Downwards from the Top.

The underlying principle of the design of the plant is that of carrying the incoming material at once to the highest point, so that all subsequent screening and crushing operations follow automatically, the material flowing by gravity over and through screens, separators and crushing machines. Water, which is an essential element in these processes, is pumped up to the same height and flows with the material. The net result is a minimum need for power, water and time.

It is of interest to note how this essential objective can be achieved if the whole plan be foreseen and operations devised to effect its achievement from the day of commencement of work at the quarry.

At Smestow, the beginning was a deposit of sand and gravel reaching from the roadside to the point where the plant was to be erected. The next step was to commence above that plane and work down to a secondary level, the height of the top of the bunkers. The junction between these two, namely, that part of the quarry cleared down to road level and that cleared down to the bunker level, was then walled and strengthened. The upper part of the plant was erected on the top level, the bunkers being built up from below.

Mr. Cross admits that at Smestow the company is in a particularly advantageous position as regards the essential supply of water. It appears that, shortly before the war, a party of prospectors from Germany was at work on the site, apparently under the impression that there was oil to be had. A shaft was sunk to a depth of 2,888 ft„ but only water was found.

Continuous Flow of Water.

That water, however, flows continuously in a quantity amply sufficient to meet the needs of the plant. It is taken to a well and thence pumped to the top level of the crushing and washing plant, from which it flows, as has been stated, with the sand and gravel through the various screens and crushers.

In the above schedule of grades, particular mention is made of one, uncrushed gravel. There is here a point of special interest. The preliminary operation after the raw material reaches the crushing and separating plant is to take out all material which will pass through a sieve. That is subsequently further screened, but the point is that nothing enters the crushers which is not larger than in.

This method ensures that everything which is sold as crushed gravel has actually been crushed and broken. No uncrushed, rounded pebbles are included. This, Mr. Cross tells me, is a matter of considerable importance to civil engineers requiring crushed gravel, namely, that it shall actually, every piece of it, be crushed. The raw material is dug -from the ground by grabs and deposited in some sturdy littlevehicles madeto Mr. W. H. Cross's own design. They are built from old-type Morris-Commercial chassis with gravitycontrolled steel tipping bodies of his own design. These deposit the material into a chute, whence it is carried by conveyor to the top of the crushing, washing and separating plant. The capacity of the conveyor is 40-50 tons per hour.

These Morris-Commercial trucks have to withstand a good deal of rough usage, and they do so extraordinarily well. Incidentally, they serve as means for training drivers for transference to the road-transport fleet if and when that occasion arises. One of the best drivers on the outside fleet was originally a driver in this team of Morris-Commercial tipping wagons.

It is interesting to note that, according to Mr. G. Cross, he has found the same underlying principle of costing to apply alike to the operation of quarries as to that of road transport. Separate figures for cost and revenue are kept for each quarry; separate figures for debit and credit are kept for each lorry. No quarry or lorry is allowed to be a " passenger."

Four Tickets for Each Load.

A feature of the detail organization which will interest many sand and gravel merchants is the arrangement concerning tickets. In the first place, there is a distinc tive colour of ticket for each quarry. This method facilitates reference in case of inquiry. For each lorry load, four tickets are issued, one for the quarry, one for the driver, one for the customer and one for the office. They are all written out together, so that there is no possibility of error as between one and another.

A particularly important point to note concerning sand and gravel operations in the Midlands is that the material is sold by weight, and not, as is the custom in London and the Home Counties, by volume. There is a weighbridge installed at each quarry, and thereby hangs a tale.

In the early days, corporation-owned weighbridges were used. This system was satisfactory until a customer complained that he was not receiving anything like the weight shown on the ticket. As the weighbridge officials were satisfied that, so far as their weighing was concerned, everything was in order, a close investigation was necessary before the leakage was discovered.

It appears that there were two weighbridges on the route followed when delivering this material. A driver would, with a full load, obtain two tickets, one from each weighbridge. His subsequent load would be under weight—so that he need not spend so long in loading and get away quickly and work in an extra journey. With this under-weight consignment he would deliver the second of the two tickets obtained with the fullweight load. Now, with a weighbridge at every quarry, this risk is completely eliminated.

Fleet Built Up Since 1915.

The fleet of 24 vehicles owned by J. Cross and Sons. Ltd., in connection with the quarries, comprises IS Bedfords, two Commers, a Guy, a Dennis, a Leyland and a Morris-Commercial. It is of especial interest to trace the growth of the fleet.

It began in 1915 with a steam wagon mounted on steel tyres, which, in the words of Mr. George Cross, voicing the views of a man responsible for the financial side of the business, "needed a canal on one side of the road and a coal mine on the other to keep it going." The change from this to a similar vehicle on solid-rubber tyres was considered to be a great advance.

A fleet comprising in the main Daimler W.D.-type vehicles was purchased soon after the war, but the family as a whole has affectionate memories of a Mack truck bought in the interbn. This vehicle, called upon to do all the hardest work and often requisitioned to taw other lorries which had broken down, gave five years of such service before it was sold. The purchase price was £135; it was sold for £300—a transaction which seriously complicates the calculation of deprecia. lion! Incidentally, I am told this old machine, is still in active' service.

The gradual change from the Daimlers to the present type was, to a considerable extent, hastened by the regulations affecting speed. the extra 10 m.p.h. permissible in those weighing under 21 tons unladen being an irresistible lure.

The Bedfords, which comprise the bulk of the fleet, give excellent service, notwithstanding the loading, which is 91 tons of nayload on the short-wheelbase models and 4f tons on the long-wheelbase units.

Good Drivers Invaluable.

Mr. Cross emphasizes what has always been stressed In this journal, namely, the advantage of good drivers. He particularly mentions the case of one vehicle, which has covered 50,000 miles in this arduous service with practically no trouble. Part of this satisfaction, Mr. Cross says, is "undoubtedly due to the fact that it is in the hands of a good driver, who takes care of it and, whenever he has half an hour to spare, spends it in going over the chassis and body to see whether there is any little attention needed, which he can give."

The provision for service is not extravagant, but appears to meet requirements. Mr. Arthur. Cross, with three mechanics, is responsible for most of it, but has the help of a blacksmith, millwright and carpenter

employed on general work in connection with the quafry machinery. There are an air compressor (tyre pressures are checked regularly), portable ramps in lieu of a pit. battery-charging and electrical servicing equipment, and four substantial tools—two lathes, a drilling machine and a milling machine—which are available when -required.

Mr. Cross tells me that he finds it preferable to purchase low-priced tyres and replace them fairly frequently. The work, as is well known, is hard on tyres and a good tyre is as easily cut as one which is not so expensive. At the time of my visit he was standardizing on Goodyear Pathfinders, from which an average mileage of 8,000-10,000 is usually to ,be expected under arduous conditions. A fair average figure for petrol-consumption rate in the case of the Bedfords is 9 m.p.g., and oil 500 m.p.g. The all-round figure for vehicle repairs averages Id. per mile.

A Thorough Costing System.

Careful records are kept of petrol and oil used, wages paid, debits on account of licences and insurance, tyres and depreciation at valuation, and actual expenditure on repairs. These entries are made as debits, and on the credit side appear the vehicle earnings as a haulage unit, and independently of the price obtained for the sand and gravel sold_ As has already been mentioned, this information is recorded independently for each vehicle and a careful watch is kept upon the ratio between cost and revenue.

A point of interest arises in connection with wages. The men are paid a flat rate, and it is generally understood that a certain number of loads per day is expected of each vehicle. If an additional load be carried, a bonus is paid. At the same time, it is recognized that conditions sometimes prevent these loads from being 'handled and no question of debiting a man on this account ever arises.