RUNNING, UPKEEP AND OVERHAUL

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Maintenance Engineers, Drivers and Mechanics.

Getting Home with a Water Leak in a Cylinder.

ONE of our correspondents, " C.T.Y.," L./writing from Peckham, sends the following interesting hint for enabling a machine to run for a short period with a cracked cylinder :—Although it is always best to remedy this trouble by welding or replacement, it is sometimes not convenient. This was the position in " C.T.Y.'s " case ; the cylinders were cracked through the inlet and exhaust ports. Finding that the water entered the sparking plug, rendering one cylinder ineffective, it was decided to

" pocket " the sparking plug. To do this he tapped the inside of an old plug and used this as an adapter to keep the sparking plug farther out of the cylinder, the distance being actually in.

It is advisable in cases of this kind to 'bend two of the points of the plug right away from the central electrode, leaving the other a little wider than is the usual practice. The points on the adapter body, if bent down vertically, will help to impede or break up any water that is likely to enter the firing plug.

It is an asset to the arrangement to fix a short piece of twisted copper wire to hold the ignition lead terminal about -6in. from the plug in order to make the current cross two gaps. This wire is attached to the firing Plug (instead of the lead), and the other end twisted around the lead. The cable is also attached to an adjacent water pipe with adhesive tape to make it as rigid as possible in order to keep constant the clearance between the terminal and plug.

The idea of using a spark gap in the wiring of the plug of the faulty cylinder is apparently suggested in order to counteract the tendency of the plug points to become bridged. In the case of a magneto having a jump-spark distributor it is best to omit this gap in the wiring to avoid unduly stressing the magneto.

Morris Valve-grinding Tool and Choked Petrol Pipe.

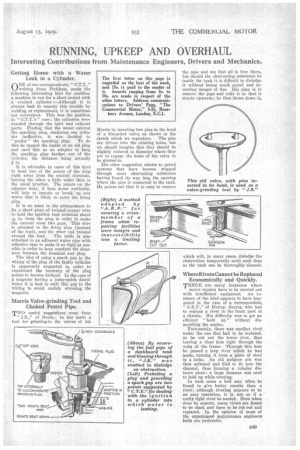

TWO useful suggestions come from J.R.," of Bootle ; be has made a tool for grinding-in the valves of his

Morris by inserting two pins in the head of a discarded valve, as shown in his sketch which we• reproduce. The pins are driven into the existing holes, but we should imagine that they should be slightly reduced in diameter where they are to engage the holes of the valve to be ground-in.

His other suggestion relates to petrol systems that have become stopped through some obstructing substance having found its way intp. the opening where the pipe is connected to the tank. He points out that it is easy to remove the pipe and see that all is free there, but should the obstructing substance be inside the tank it is difficult to dislodge it without losing much petrol and incurring danger of fire. His plan is to remove the pipe and refix it so that it stands upwards ; he then blows down it, which will, in many cases, dislodge tbe obstruction temporarily until such time as the tank can be thoroughly cleaned.

Where Rivets Cannot be Replaced Economically and Quickly.

THERE are many instances where

motor repairs have to be carried out with insufficient equipment. An instance of the kind appears to have happened in the case of a correspondent, " A.R.P.," of Horley, Surrey, who had to replace a rivet in the front part of a chassis. His difficulty was to get an efficient " hold up" without dismantling the engine.

Fortunately, there was another rivet under the one that had to be replaced, so he cut out the lower rivet, thus leaving a clear hole right through the webs of the frame. Through this hole he passed a long rivet which be had made, turning it from a piece of steel in a lathe. An old gudgeon pin was then softened and filed to fit into the channel, thus forming a tubular distance piece ; a large hammer was used to hold up while riveting.

In such cases a bolt may often be found to give better results than a rivet; although riveting appears to be an easy operation it is not so if a really tight rivet 13; needed. Even when done by experts, many rivets are found to be slack and have to be cut out and replaced. In the opinion of most of the experienced maintenance engineers bolts are preferable.