THE DESIGN OF

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

SEATS FOR COACHES AND BUSES

Some Helpful Information on the Subject of the Construction of Bus and Coach Seats and Advice as Regards the Choice of Upholstery.

THE" seat of the motorbus or coach is not only an essential feature but its detail design is of ever-increasing importance, because the comfort and appearance of the seat continues to be a dominating factor in the development of the public-travel facilities which now extend to all parts of the country.

It may• be expected, therefore, that thg design and construction of the seat has received much attention during the past few years, leading to the creation of several types and improvements, as well as to a certain degree of standardization.

As the seat is a separate structure, it is often made in factories which specialize in the production of components, although many are the work of the seat-construction departments of the various bodybuilding concerns. It is estimated that between 70,000 and 80,000 bus and coach seats, each to hold two passengers, are made annually.

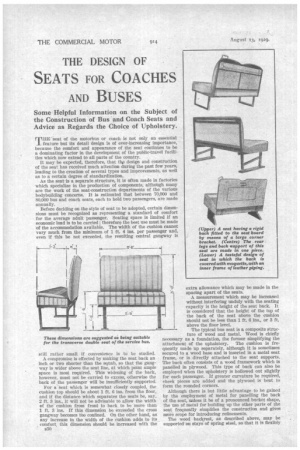

Before deciding on the style of seat to be adopted, certain dimensions must be recognized as representing a standard of comfort for the average adult passenger. Seating space is limited if an economic load is to be carried ; therefore the best use must be made of the accommodation available. The width of the cushion cannot vary much from the minimum of 1 ft. 4 ins, per passenger and, even if this be not exceeded, the resulting central gangway is still rather small if convenience is to be studied.

A compromise is effected by making the seat back an inch or two shorter than the squab, so that the gangway is wider above the seat line, at which point ample space is most required. This widening of the back, however, must not be carried to excess, otherwise the back of the passenger will be insufficiently supported.

For a seat which is somewhat closely coupled, the cushion top should be about 1 ft. 6 ins, from the floor, and if the distance which separates the seats be, say, 2 ft. 8 ins., it will not be advisable to allow the width of the cushion from front to back to be more than 1 ft. 3 ins. If this dimension be exceeded the cross gangway becomes too confined. On the other hand, as any increase in the width of the cushion adds to its _ comfort, this dimension should be increased with the B30 extra allowance which may be made in the spacing apart of the seats.

A measurement which may be increased without interfering unduly with the seating capacity is the height of the seat back. It is considered that the height of the top of the back of the seat above the cushion should not be less than 1 ft. 6 ins., or 3 ft. above the floor level.

The typical bus seat is a composite structure of wood and metal. Wood is chiefly necessary as a foundation, the former simplifying the attachment of the upholstery. The cushion is frequently made up separately, although it is sometimes secured to a wood base and is inserted in a metal seat frame, or is directly attached to the seat supports. The back often consists of a wood framework which is panelled in plywood. This type of back can also be employed when the upholstery is hollowed out slightly for each passenger. If greater curvature be required, cheek pieces are added and the plywood is bent to form the rounded corners.

Although there is but little advantage to be gained by the employment of metal for panelling the back of the seat, unless it be of a pronounced bucket shape, the use of metal for building up the other parts of the seat frequently simplifies the construction and gives more scope for introducing refinements.

The wood backrest, as described above, may be supported on stays of spring steel, so that it is flexibly mounted. This form of construction is still popular, although there is quite as much demand for a seat having a rigid back, in which any special degree of comfort that is afforded depends upon the shaping and resilience of the upholstery, rather than on its means for support.

A steel ilitch-plate may be used to reinforce the rear leg when it is constructed in one piece with the back support, but, at the present time, sheet steel is more often eroployed for this part of the seat, for the purpose of forming a large corner bracket uniting the back and seat board. Alternatively,,a casting or stamping may be utilized, which consists of a combined seat and back support. If the seat support be an independent part of the structure, there is more scope for

designing it so that it offers the minimum amount of floor obstruction.

Regarding the upholstery, it is an advantage if the foundation of the cushion has a large number of springs, because, in that case, the weight of the passenger is more evenly distributed. For the longdistance vehicle extra comfort is afforded by the use of superimposed springs and separate cushions. Occasionally, springs may also be inserted in the back squab. There is only an inch or two available for them and skill is required in their arrangement if they are to be effective. The claims made for the pneumatic type of cushion should not be overlooked, because it is compact and hygienic, and provides a high degree of comfort.

A seat, which is upholstered in plain leather or leather cloth is apt to look somewhat dull and cold, so that it is desirable that it should have some relief in the form

of a simple or fancy graining. Moquettes are particularly attractive owing to the range of patterns which is available. In some instances, a bold and striking pattern of moquette is used for covering the whole of the exterior of the seat. This may suit sonic tastes, but, on the other hand, many will prefer a more restrained design, or the toning down of the colour scheme by trimming the seats partly with a darkcoloured plain leather.

A combined trimming of moquette and leather lends itself to much variation and gives the interior of the coach a novel and tasteful effect.

Regarding the finish of the back of the seat, this is now seldom of plain varnished wood, even in the case of the service bus. Many seats are completely covered at the back with hair carpet or moquette, but they both look better when they form panels surrounded by the wood framework or applied mouldings. An inner framework may also be made of a .piping or banding of leather. A large expanse of seat back also appears much lighter if a panel of cane or basket-work be inserted.