Lightweight Low-height Steel Bodies

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

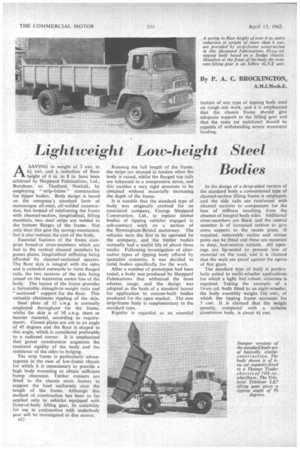

ASAVING in weight of 2 cwt. to 61 cwt. and a reduction of floor height of 6 in. to 8 in. have been achieved by Sheppard Fabrications, Ltd., Burnham, nr. Thetford, Norfolk, by employing " strip-frame " construction for tipper bodies. Body design is based on the company's standard form of monocoque all-steel, all-welded construction, but instead of reinforcing the frame with channel-section, longitudinal, lifting members, two steel strips are welded to the bottom flanges of the frame. Not only does this give the savings mentioned, but it also reduces the cost of the body.

Essential features of the frame cornprise boxed-in cross-members which are tied to the vertical channel members by gusset plates, longitudinal stiffening being afforded by channel-sectioned spacers. The floor skin is integral With the sides and is extended outwards to form flanged rails, the two sections of the skin being joined on the transverse centre line of the body. The layout of the frame provides a favourable strength-to-weight ratio and "sectioned" support for the floor. This virtually eliminates rippling of the skin.

Steel plate of 12 s.w.g. is normally employed throughout for the frame, whilst the skin is of 10 s.w.g. sheet or heavier material, according to requirements. Gusset plates are cut to an angle of 45 degrees and the floor is shaped to this angle, which is considered preferable to a radiused corner. It is emphasized that gusset construction augments the torsional rigidity of the body and the resistance of the sides to bulging.

The strip frame is particularly advantageous in the case of low-frame chassis for which it is unnecessary to provide a high body mounting to obtain sufficient bump clearance. Timber runners are fitted to the chassis main frames to support the load uniformly over the length of the frame. Although this method of construction has been so far applied only to vehicles equipped with front-of-body lifting gear, its suitability for use in conjunction with underbody gear will be investigated in due course,

n12 Running the full length of the frame, the strips arc stressed in tension when the body is raised, whilst the flanged top rails are subjected to a compressive stress, and this enables a very rigid structure to be obtained without materially increasing the depth of the frame.

It is notable that the standard type of body was originally evolved for an associated company, George Sheppard Construction, Ltd„ to replace timber bodies of tipping vehicles engaged in sub-contract work on a section of the Birmingham-Bristol motorway. The vehicles were the first to be operated by the company, and the timber bodies normally had a useful life of about three weeks. Following investigation of alternative types of tipping body offered by specialist concerns, it was decided to build bodies specifically for the work.

After a number of prototypes had been tested, a body was produced by Sheppard Fabrications that withstood the most adverse usage, and the design was adopted as the basis of a standard layout for application to custom-built bodies produced for the open market. The new strip-frame body is supplementary to the standard type.

Rigidity is regarded as an essential In the .design of a drop-sided version of the standard body a ,conventional type of channel-section lifting frame is employed, and the side rails arc reinforced with channel sections to compensate for the loss of stiffness resulting from the absence of integral body sides. Additional cross-members are fitted, and the central member is of increased section to give extra support to the centre posts. If required, removable centre and corner posts can be fitted and these are mounted in deep, box-section sockets. All openings are lip-sealed to prevent foss of material on the road, and it is claimed that the seals are proof against the egress of fine grain.

The standard type of body is particularly suited to multi-wheeler applications for which a light, but robust, structure is required. Taking the example of a 14-cu.-yd. body fitted to an eight-wheeler, the body assembly weighs 241 cwt., of which the tipping frame accounts for 7 cwt. It is claimed that the weight penalty, compared with a suitable aluminium body, is about 4f cwt.