Volvo F89

Page 59

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

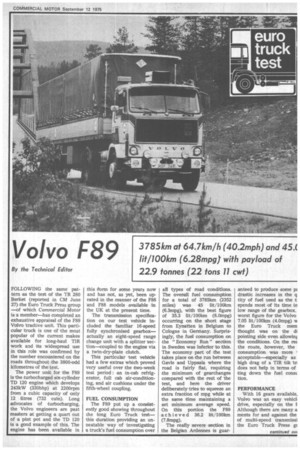

By the Technical Editor FOLLOWING the same pattern as the test of the TR 280 Berliet (reported in CM June 27) the Euro Truck Press group —of which Commercial Motor is a member—has completed an exhaustive appraisal of the F89 Volvo tractive unit. This particular truck is one °If the most popular of the current makes available for long-haul TIR work and its widespread use in this role was confirmed by the number encountered on the roads throughout the 3800-odd kilometres of the test.

The power unit for the F89 is the turbocharged six-cylinder TD 120 engine which develops 243kW (330bhp) at 2200rpm from a cubic capacity of only 12 titres (732 cuin). Long advocates of turbodharging, the Volvo engineers are past masters at getting a quart out of a pint pat and the TD 120 is a good example of this. The engine has been available in this form for some years now and has not, as yet, been uprated in the manner of the F86 'and F88 models available in the UK at the present time.

The transmission specification on our test vehicle included the familiar 16-speed fully 'synchronised gearbox— actually an eight-speed range change unit With a .splitter section--coupled. to the engine via a twin-dry-plate clutch, This particular test vehicle had a few extras whith proved very useful over the two-week test period : an in-cab refrigerator, full cab airconditioning, and air cushions under the fifth-wheel coupling.

FUEL CONSUMPTION The F89 put up a consistently good showing throughout the long Euro Truck test— this duration providing an unbeatable way of investigating a truck's fuel consumption over all types of road conditions. The overall fuel consumplbion for a total of 37851an (2352 miles) was 45 lit/100km (6.3mpg), with the best figure of 35.3 lit/100km (8.0mpg) occurring on the short Stage from Eynatten in Belgium to Cologne in Germany. Surprisingly, the fuel consumption on the "Economy Run" 'section in Sweden was inferlior to this. The economy part of the test takes place on 'the run between Gavle and Uppsala where the road is fairly fiat, reqtiiring the minimum of gearchanges compared with the rest of the test, and here the driver deliberately tries to squeeze an extra fraction of mpg while at the same time maintaining a set minimum average speed. On this portion the F89 achieved 36.2 lit/100km (7.8mpg).

The really severe section in the Belgian Ardennes is guar anteed to produce some pi drastic increases in the q tity of fuel used as the t spends most of its time in low range of t...he gearbox. worst figure for the Volvo 7.05 lit/100km (4.0mpg) w the Euro Truck mem thought was on the di pointing side even allowinf the conditions. On The res the route, however, the consumption was more acceptable—especially as high drag of a TIR tilt tit does not help in terms of ting down the fuel cons]: Lion.

PERFORMANCE With 16 gears available, Volvo was an easy veirict drive, especially on the Although there are many a ments for and against the of multi-speed transmissi the Euro Truck Press gi : unanimous that the Volvo nn was first class as the ratio was always avail whatever the conditions e the driver was still at ty to skip gears When on . roads. In ;feet on the relay fiat roads found in mi. Sweden I tended to from rest in .second low Then proceed to fourth and filth low, only using ;splitter from ;Sixth gear aids. On the hilts, 'how the split-second change 'ded by the splitter was inable—it was possible to ge up when going up a gradient and only lose It 300 rpm, a useful ith the various speed a in force throughout pe the maximum speed of Volvo was really of acaic interest only.With the er output of 242kW bhp) available it did mean, ever, that the engine was acting, in most Circtunces, 'comfortably within its s with a consequent beneD the fuel consumption.

HE CAB le Volvo cab was ;heavily dised by most of the Euro lc group. Although the was originally la breakugh in combining driver fort With the requirements he Stringent Swedish im regulations, most of the felt that the oohs from European competition had left the Volvo well behind. ras not that the F89 cab uncomfortable—far from Itt it was felt to be rather iped with the intruSion of engine cowl: into the cab, all the drivers -criticised the Ality. This problem of adee visibility is something .causes a lot of head aches to the Scandinavian designers because of the need to meet the impact regulations as well. I -can't help wondering Whether a pillar along the lines of the _Seddon Atkinson 400 design Might do the trick, where the thickness is along the line of sight of the driver and not across it.

The noise level in the cab was well below the level of discomfort although it was obvious when the engine was really trying—the whine from the blower made its presence felt.

Although it was not a " 'standard " part of the Volvo equipment, the optional air conditioning is now being requested more and more by Continental operators — especially in Sweden. It worked well in two respects an the Euro Truck test. The obvious advantage was that it kept the cab cool in the middle of a very sticky .European summer but it brought the added attraction of allowing the driver to keep the windows shut, with a 'consequent reduction in noise level.

RIDE AND HANDLING The two professional drivers employed by Euro Truck Press (who shared the driving with the Volvo works driver and the journalists) both drive Volvos in their everyday employment. Beth Daniel Laloue and Louis Soharpe handle F88s regularly and they were very impressed With the ride of the F89, rating it as far superior to their usual 88s. There was quite a long discussion as to the reasons for this and we .came up with three different solutions although the Volvo engineers would not commit !themselves as to which was the most likely I The first suggestion was that the effect of the air cushions under the fifth-wheel coupling damped out much of the pitching motion about this point and the second concerned the slight variation in weight distribution compared with the 88. The third ;suggestion—and the one I put my money on—was that the teat 89 was fitted with Volvo's relatively new parabolic suspension which cuts down interleaf friction and gives a softer ride. The earlier 88s of the Euro Truck men had the earlier, conventional, semielliptic suspension.

The general ride and handling of the Volvo was praised by everyone and I would go so far as to say that this was the best feature of the 89 no far as I was concerned. It had a " taut " ride which gave the driver confidence on corners because of the lack of roll (either cab Or vehiele) yet the system was still soft enough to remain comfortable even on the toughest of roads.

One characteristic of the suspension that I did not particularly like was the way the truck tended to wallow on relatively 'smooth roads with long undulations. This was something 1 noticed on my first (brief) test of an 89 fitted with the system some 18 months ago so, whatever causes it, Volvo have not yet found the answer.

FACE TO FACE The technical meeting between the Euro Truck Press group and the Volvo personnel unearthed some interesting facts. The Swedish company had wheeled out some of . its big guns for this discussion by having on hand Ben:Al Haggh (chief engineer—engines), Per Olaf Eker (thief engineer— transmissions) and Hans Engdahl (general sales manager).

As expected, a large part of the discussion was taken up with the cab. In 'answering the many. criticisms • of the 89 on this aspect Hans Engdahl made the point that " you become market leaders with various new features on a truck then sooner or later the opposition will catch you up. This is the Situation Volvo are now in but we think the cab can live many more years yet. We do have a new cab—or at least a facelift —which will be seen at Frankfurt in September." (This has now happened—see CM last week.) Several of the drivers commented that while it was easy to get into the Volvo it required a great deal more care when getting out—a problem certainly not peculiar to Volvo. The offidial reply to this was that getting in and out easily was not so important on the F89 which was, after ,all, designed for long-haul work. It was not •a local delivery vehicle requiring the driver to get in and out four times every kilometre. Louis Scharpe commented that it was easy to fall out of 'the Volvo if you were not careful, ,as it was difficult to see the steps--and he had been driving Volvos for years.

Lars-Ake Weimar, one of the engineers who accompanied the truck throughout the whole route, said that it was difficult to suggest in pradtiee the easiest way out of the cab but the official Volvo recommendation was to come out backwards.

Answering critieism of the noise 'entering the cab via the gear-lever gaiter, the Volvo men _said this problem should be cured on the face-lifted cab by :better insulation. One suggesticm was made that this noise path was 'exaggerated by the Volvo method of fixing the gear-lever linkage to the engine, Per Olof Eker replied that this was the best method with a Volvo as there was nowhere else Ito go 'Without increasing the number of joints in the 'linkage.

The discussion on the F89 suspension gave an indication of the way the Vdlvo development engineers work. The parabolic suspension on the tractive units was developed because 80 per cent of the Volvos sold were tractive units and the 'customers were not very happy with the ride. To investigate this, Volvo rented trucks from all its competitors. Hans Engdahl recalled: "We tested every 'heavy truck in Europe with the exception of the Pegaso—or the Ford, of course, which was not built then ! " Microphones were Attached to the dampers and the front or the rear. These were carried out mainly olland and Hans Engdahl ied that as a result ' we the best suspension on truck market today." A ment which was not chalmi by •any of the Euro k Press group.

iII on the subject of the the air-damped fifth-wheel ling was apparently used loving valuable and fragile was not a Volvo )onent.

though the engine was ed by the journalists and !rs, many were agreed that mit was on the small side uch a power output. Bertil 11 replied : "In a way I but you must remember it was designed to take more at the drawing d stage. We have reached W (460bhp) with this le on test-but that was not completely 'without problems! But you must be careful. Each step to increase the horsepower must also include a step to at least maintain the engine life. We once had a problem with exhaust valves breaking but this was solved with double springs. We have run on test like this for half an hour at 3200rpm Without problems but of course the valvebounce speed can differ from engine to engine because of varying tolerances."

The recommended rev range for the TD 120 engine goes down to 1300rpm. When asked if it was advisable to let the engine go down to this speed Bertil Haggh said this was quite in order. "These speed limits shown in green are recommended because between them the engine is working at its best efficiency. The higher the engine speed the more the inertia forces compensate for the combustion forces."

The TD 120 engine was launched in October 1971 and Bertil Haggh was asked what had Volvo done to it since.

"We have made a lot of m inor improvements but nothing major. We had a leakage problem with the cylinders which was overcome by the introduction of a third sealing ring. We have improved the exhaust valve life by using a better material and added double springs to both inlet and exhaust valves-and we have changed the oil filter system. With the early system the oil cooler rsometimes contaminated the system with welding swan f so the filter has now been moved to after the cooler in the circttit."

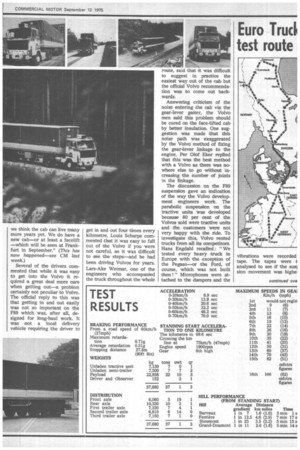

The sum of opinions on the F89's main features can be seen in the " voting " panel.