Torque converter transmission in new £2,200 AVS Marina

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

The converter is housed in a standard Model 65 Borg Warner 'automatic transmission housing. On the Marina the second gear band 'is used to improve acceleration from Standstill to about 15mph, When it changes up and the torque converter takes over.

In The Hobbs design of torque converter an extra turbine is introduced between the impeller and the output turbine and is geared to the impeller, 'the output shaft and transmission casing by epicyclic gears. The extra turbine is known as the circulatory turbine and because of the gearing It may run faster or slower than the impeller according to circumstances. The effect of all this is to increase both stall torque ratios and efficiencies throughout the speed range.

In 'addition the vanes of the circulatory -turbine may be adiusted to alter the converter characteristics. In some applications it is desirable to have 'the vanes adjusted while revolving to provide, for example, an effective neutral. In the van application the vanes are set at 21 degrees and are nonadjustable. This greatly reduces the cost of the converter and is quite satisfactory where the input shaft speed is near constant. The benefits to be gained over a normal torque converter are considerable. In a conventional three-element torque converter a stall torque ratio of over 3: 1 is possible but at the expense of very low efficiency at coupling (when the unit effectively becomes a solid drive). Alternatively, it is possible to obtain 'high coupling efficiency but at 'the expense of a lower stall torque ratio— something like 2.2:1.

With 'the Hobbs unit, however, improvement in efficiency is over 25 per cent in places and the stall torque ratio is increased from 3 : 1 to 4.8: 1.

Like a petrol engine

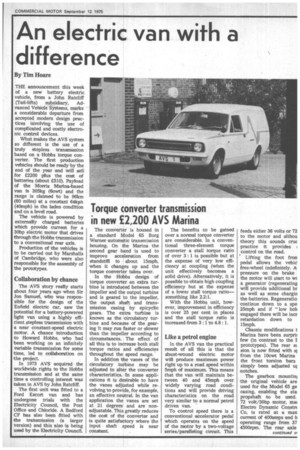

In the AVS van the practical result of all this is that the Shunt-wound electric motor Will produce maximum power right up to a road speed within 5mrph of maximum. This mean's that the van will maintain between 40 and 45mph over widely varying road conditions and will provide driving characteristics on the road very similar to a normal petrol driven van.

To control speed there is a conventional accelerator pedal 'which operates on the speed of the motor by a two-voltage series/paralleling circuit. This feeds either 36 volts or 72 to the motor and althou theory this sound's cruc practice it provides control on 'the road.

Lifting the foot fron pedal allows the vehid free-wheel 'indefinitely. Apressure on 'the brake the motor will start to wt 'a generator (regenerating will provide additional br as well as some chargin the batteries. Regeneratio continue down to a spe 25mph and if "low hol< engaged there will be incr retardation dawn to 15mph.

Chassis 'modifications t Marina have been surprh few (in contrast to the prototype's). The rear st sion is now fitted with si from the lOcwt 'Marina the front torsion bars simply been adjusted ur notthes.

The gearbox mountim the original vehicle are used for the .Model 65 ge casing, enabling the sta propshaft to be used. 72 volt/30hp motor, mal Electro Dynamic Constn Co, is rated at a max current. of 400arnps and h operating range from 37 4500rpm. The rear axle