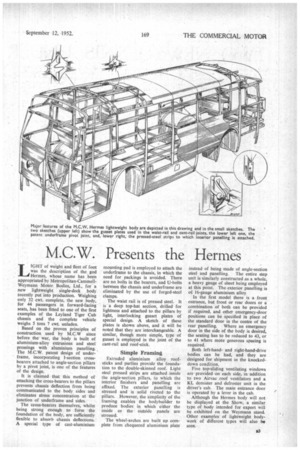

M.C.W. Presents the Hermes L IGH1' of weight and fleet of

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

foot was the description of the god Hermes, whose name has been appropriated by Metropolitan-CammellWeymann Motor Bodies, Ltd., for a new lightweight single-deck body recently put into production. Weighing only 32 cwt. complete, the new body. for 44 passengers in forward-facing seats, has been fitted to one of the first examples of the Leyland Tiger Cub chassis and the complete vehicle weighs 5 tons 7 cwt. unladen.

Based on the proven principles of construction used by M.C.W since before the war, the body is built of aluminium-alloy extrusions and steel pressings with aluminium panelling. The M.C.W. patent design of underframe, incorporating 1-section crosshearers attached to angle-section pillars by a pivot joint, is one of the features of the design.

It is claimed that this method of attaching the cross-bearers to the pillars prevents chassis deflection from being communicated to the body sides and eliminates stress concentration at the junction of underframe and sides.

The cross-bearers themselves, whilst being strong enough to form the foundation of the body, are sufficiently flexible to absorb chassis deflections. A special type of cast-aluminium mounting pad is employed to attach the underfa-ame to the chassis, in which the need for pack ings is avoided. There are no bolts in the bearers, and U-bolts between the chassis and underframe are eliminated by the use of forged-steel clamps.

The waist rail is of pressed steel. It is a deep top-hat section, drilled for lightness and attached to the pillars by light, interlocking gusset plates of special design. A sketch. of these plates is shown above, and it will be noted that they are interchangeable. A similar, though more simple, type of gusset is employed in the joint of the cant-rail and roof-stick.

Simple Framing Extruded aluminium alloy roofsticks and purlins provide the foundation to the double-skinned roof. Light steel pressed strips are attached inside the angle-section pillars, to which the interior finishers and panelling are affixed. The exterior panelling is stressed and is solid riveted to the pillars. However, the simplicity of the framing enables the bodybuilder to produce bodies in which either the inside or the outside panels are stressed.

The wheel-arches are built up complete from chequered aluminium plate instead of being made of angle-section steel and panelling. The entire step unit is similarly constructed as a whole, a heavy gauge of sheet being employed at this point. The-exterior panelling is of 16-gauge aluminium alloy

In the first model there is a front entrance, but front or rear doors or a combination of both can be provided if required, and other emergency-door positions can be specified in place of the standard door in the centre of the rear panelling. Where an emergency door in the side of the body is desired, the seating has to be reduced to 43, or to 41 where more generous spacing is required.

Both left-handand right-hand-drive bodies can be had, and they are designed for shipment in the knockeddown condition..

Five top-sliding ventilating windows are provided on each side, in addition to two Airvac roof ventilators and a KL demister and defroster unit in the driver's cab. The main entrance door is operated by a lever in the cab.

Although the Hermes body will not be displayed at the Show, a similar type of body intended for export will be exhibited on the Weymann stand. Other examples of lightweight bodywork of different types will also be seen.