K hh)tIi% I WORK

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

III\ 111UNIIS ON 1111 110/1

WITH many features outstanding in design, the Leyland PD 2/i oil-engined bus chassis proved itself a worthy successor to the renowned title of the Titan class when subjected to road test.

Incorporating the new Leyland "0600" engine and synchromesh gearbox, the chassis proved lively and exhilarating to drive, appearing to make light work of the load carried. The six-cylindered 9.8-litre engine, with 4.8-in, bore and 5.5-in, stroke, employs a standard toroidal-cavity piston and " four spray" injectors. Fuel is metered to the injectors a•C.A.V. pump fitted with a Leyland-C.A.V. pneumaticcentrifugal governor mechanism. A feature of the pump design -is a small flywheel on the driving coupling, which dampens the pumping oscillation.

Mounted as a unit, the engine, clutch and gearbox are suspended by shackles which constrain the unit to oscillate on an axis between its centre of gravity and the front propeller shaft, thereby almast eliminating engine vibration. Pre-loaded rubber bushes fitted to the suspension shackles are held in compression by the shackle plates.

A new feature in the monobloc crankcase and cylinderblock casting is the prefinished dry-type cylinder liner, which can be replaced with the engine in position. This obviates reboring, as replacement liners, together with standard pistons, may be fitted when required.

The twin detachable cast-iron cylinder heads, which are of identical design, incorporate Stellite-faced valve seats frozen in position. Operated by long pushrods and rocker levers, the valves are Stellite-faced, and the valve stems chromiumplated.

With balance weights to relieve the main journals of centrifugal loading, the crankshaft has a rubber-bonded damper at the front end, to eliminate torsional vibration.

Drive to the camshaft, exhauster, and fuel pump is through a helical train of gears, which has closely con

trolled limits to promote silent running. The Clayton Dewandre rotary exhauster is driven at half engine speed in a common drive to the fuel pump. A twin V-belt. driven from a pulley on the front of the crankshaft, links up the dynamo, water pump, and fan units.

The dry, single-plate clutch, with a 161-in.-diameter facing, is ensured a long life by non-metallic linings, which are in. thick on the flywheel side and In thick on the pressure-plate side.

Fast, but silent, gear-changes are facilitated by large synchronizing .cones fitted to second, third and fourth gears. Exhaustive road and bench tests have failed to reveal any weakness in the synchronizing.units. Helical gears are used for second and third ratios, to ensure quietness in operation.

An interesting point about the offset, underslung worm of the rear axle is the use of renewable strip-type thrust bearings on. the differential pinions and axle-shaft bevel wheels. The fully floating axle has additional features of involute splining on the shafts and detachable cone oil seals.

The Marles cam and double-roller steering gear provides light but accurate control at all toad speeds.

Leyland-Metalastik rubber-bonded shackle hushes absorb rotary movement between the shackle pins and spring eyes. The system eliminates the 12 lubricating points common to normal bronze bushes. • Actuated through a.Dewandre servo, the front brake cylinders are mounted directly over the stub axles, whilst the rear brakes are directly linked to the servo.

. The chassis frame, a rigid structure of 11 ins. by 3 ins. by I in. thick, is made from an alloy steel pressing of channel section. It is noticeable. that the chassis cross-members have been machined to fit snugly inside the frame, and the body brackets linked up to utilize the same holes. As an example, the engine rear cross-member, machined to fit the frame, is bolted through to the combined spring and body bracket located on the outside of the frame.

This relieves the frame of shear stresses and reduces the number of holes drilled in the side members.

An almost universal use ot Simmonds nuts has been made throughout the chassis, castellated nuts and split pins being used only on the brake levers.

Having first delved into the chassis specification we fitted up a fuel test tank, and made our way to the public weighbridge. The running weight was found to he 11 tons 81 cwt., rather high for our test, but a good representative load for a double-decker bus with several standing passengers.

We decided to take the normal Leyland test route, which. proceeding towards Hutton. meant a climb of Sheep Hill This proved no obstacle to the Leyland as we romped up in second gear at maximum engine revs., so we decided to turn off the route to climb Whittle Hill, a 1-in-5 gradient. An attempt to change from bottom to second gear was found to be just too much for the engine, so, changing back to the lower gear we climbed the hill at 8 m.p.h., which was the maximum speed of that ratio. it was obvious that it would be difficult to find a hill which would be insurmountable by this chassis.

I had taken over driving from the ascent of Whittle Hill. so it was my pleasure to make the fast run to the dual carriageway of the Liverpool Road. I say pleasure, because of the light handling, coupled with fast acceleration and easy gear-changing. Maximum governed speed in top gear was found to be 43 m.p.h., a final-drive ratio of 5.4 to being used in this chassis.

The chassis held the road in a remarkable manner, and, with good braking giving every confidence, it was exhilarating to eat up the miles on the open road. Rapid gearchanges from top to third were easily made on fast cornering and overtaking, it being necessary only to leave the accelerator fully open while the clutch was disengaged and the gear lever moved straight across from " top" to third."

Arriving at the point selected for the acceleration tests, we made a check of running temperatures. With an atmospheric temperature of 79 degrees F., the radiator temperature was 169 degrees F., engine lubricating oil 157 degrees F., gearbox 128 degrees F., and differential temperature 160 degrees F. With a body fitted, it is to be expected that slightly higher temperatures would be recorded for the gearbox and differential.

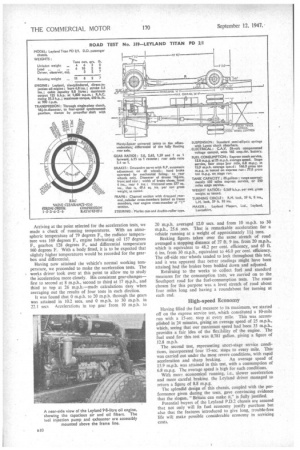

Having now attained the vehicle's normal working temperature, we proceeded to make the acceleration tests. The s works driver took over at this point to allow me to study the acceleration more closely. His consistent gear-changesfirst to second at 8 m.p.h., second to third at 17 m.p.h., and third to top at 26 m.p.h.-made, calculations easy when averaging out the results of four tests in each dirction, It was found that 0 m.p.h. to 20 m.p.h. through the gears was attained in 10.2 secs. and 0 m.p.b. to 30 m.p.h. in 22.1 secs Accelerations in top gear from 10 m.p.h. to

20 m.p.h, averaged 12.0 secs. and from 10 m.p.h. to 30 m.p.h., 25.6 :lees. That is remarkable acceleration for a vehicle running at a weight of approximately 1l tons.

Braking figures taken over the same stretch of road averaged a stopping distance of 27 ft. 9 ins. from 20 m.p.h., which is equivalent to 48.2 per cent. efficiency, and 65 ft. 6 ins. from 30 m.p.h., equivalent to 46.0 per cent. efficiency. The off-side rear wheels tended to lock throughout this test, and it was apparent that better geadings might have been attainesi had the brakes been bedded down and adjusted.

Returning to the works to collect fuel and standard meaSures for the consumption tests, we carried on to the Southport road for the fuel-consumption tests. The route chosen for this purpose was a level stretch of road about four miles long and having a roundabout for turning at each end.

High-speed Economy

Having filled the fuel measure to its maximum, we started off on the express service test, which constituted a 10-mile run with a 15-sec. stop at every mile. This was accomplished in 24 minutes, giving an average speed of 25 m.p.h., which, seeing that our maximum speed had been 35 m.p.h., provides a fair idea of the flexibility of the engine. The fuel used for this test was 0.781 gallon, giving a figure of 12.8 m.p.h. The second test, representing snort-stage service conditions, incorporated four 15-sec. stops to every mile. This was carried out under the most severe conditions, with rapid acceleration and sharp braking. An average speed of 15,9 m.p.h. was attained in this test, with a consumption of 6.8 m.p.g. The average speed is high for such conditions. With more economical running, i.e., slower acceleration and more careful brakine. the Leyland driver manned to return a figure of 8.8 m.p.g.

The splendid design of this chassis, coupled with the performance given during the tests. gave convincing evidence that the slogan, "Britain can make it." is fully justified. Potential buyers of the Leyland P.D.2 chassis are assured that not only will its fuel economy justify purchase but also that the features introduced to give long, trouble-free life will make possible considerable economy in servicing costs.