Specialized Leyland Tractors for Timber Work

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

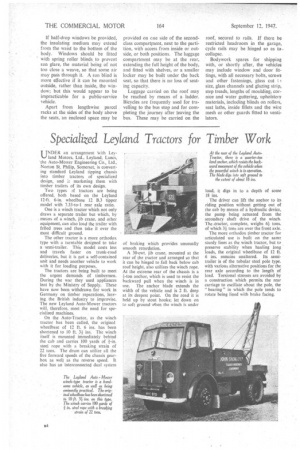

VENDER an arrangement with LeykJ land Motors, Ltd., Leyland, Lanes, the Auto-Mower Engineering Co., Ltd., Norton St. Philip, Somerset, is converting standard Leyland tipping chassis into timber tractors of specialized design, and c marketing them with timber trailers of its own design.

Two types :A tractors are being offered, both based on the Leyland12-ft. 6-in. wheelbase 12 B.3 tipper model .with 7.33-to-1 rear axle ratio. One is a winch tractor which not only draws a separate trailer but which, by . means of a winch, jib crane, and other equipment, can also load the trailer with felled trees and then take it over the most difficult ground.

The other tractor is a more orthodox • type with a turntable designed to take a semi-trailer. This model costs less and travels faster on trunk-road deliveries, but it is not a self-contained unit and needs another vehicle to work with it for loading purposes.

The tractors are being built to meet the Urgent demands of timbermen. During the war they used appliances lent by the Ministry of Supply. These have now been withdrawn for work in Germany on timber reparations, leaving the British industry to improvise. The new Leyland Auto-Mower tractors will, therefore,meet the need for specialized machines.

On the Auto-Tractor, as the winch tractor has been called, the original wheelbase of 12 ft. 6 ins, has been shortened to 10 ft. 3i ins: The winch itself is mounted immediately behind the cab and carries 100 yards of 1-in. steel rope with a breaking strain of 22 tons. The drum can utilize all the five forward speeds of the chassis gearbox as well as the reverse speed. It also has an interconnected dual system of braking which provides unusually smooth retardation.

A 30-cwt. jib crane, mounted at the rear of the tractor and arranged so that it can be hinged to .fall back below cab roof height, also utilizes the winch rope. At the extreme rear of the chassis is a 1-ton anchor, which is used to resist the backward pull when the winch is in use. The anchor blade extends the width of the vehicle and is 2 ft. deep at its deepest point. On the road it is held up by stout hooks; let down on to soft ground %ihen the winch is under load, it digs in to a depth of some 18 ins.

The driver can lift the anchor to its riding position without getting out of the cab by means of a hydraulic device, the pump being actuated from the secondary shaft drive of the winch. The tractor, complete, weighs 6* tons. of which 31 tons are over the front axle.

The more orthodox timber tractor for articulated use is built on the same sturdy lines as the winch tractor, but to preserve stability when hauling long loads, the original wheelbase of 12 ft. 6 ins, remains unaltered. Its semitrailer is of the tubular steel pole type, with various alternative positions for the rear axle according to the length of load. Torsional stresses are avoided by a construction which permits the rear carriage to oscillate about the pole, the " bearing " in which the pole tends to rotate being lined with brake facing.