Vehicles in the Trials.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

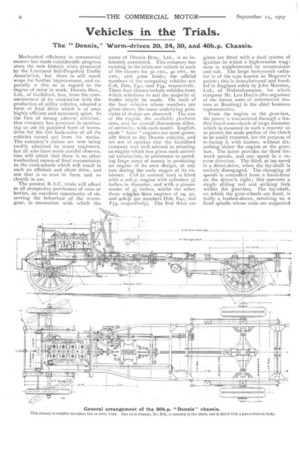

The "Dennis," Worm-driven 20, 24, 30, and 40h.p. Chassis.

Mechanical efficiency in commercial motors has made considerable progress Since the now historic trials promoted by the Liverpool SelfLPropelled Traffic Association, but there is still much scope for further improvement, and especially is this so in regard to the degree of noise in work. Dennis Bros., Ltd., of Guildford, has, from the commencement of its association with the production of utility vehicles, adopted a form of final drive which is at once highly efficient and extremely quiet. In the face of strong adverse criticism, that company has persisted in continuing to use its patented form of warmdrive for the live back-axles of all the vehicles turned out from its works. The company's claims are now being tardily adrriitted by many engineers, but all who have made careful observation will admit that there is no other mechanical means of final transmission to the road-wheels which will result in such an efficient and silent drive, and one that is so neat in form and so cleanly in use.

The present R.A.C. trials will afford to all prospective purchasers of vans or lorries, an excellent opportunity of observing the behaviour of the wormgear, in connection with which the

name of Dennis Bros., Ltd., is so intimately associated. This company has running in the trials one vehicle in each of the. classes for 30 cwt., 40 cwt., 60 cwt., and 5-ton loads ; the official numbers of the competing vehicles are C18, D26, E41, and F54, respectively. These four classes include vehicles from which selections to suit the majority of trades might be made. On each of the four vehicles whose numbers are given above, the same underlying principles of design are observed. The size of the engine, the available platform area, and the overall dimensions differ, of necessity, with each model. Englishmade " Aster "engines arc most generally fitted to the Dennis vehicles, and we are of opinion that the Guildford company was well advised in selecting an engine which has given such universal satisfaction, in preference to Spending large sums of money in producing an engine of its own design, at any rate during the early stages of its existence. Cr8 (a covered van) is fitted with a 2oh.p. engine with cylinders 3.',1 inches in diameter, and with a pistonstroke of 5,1 inches, whilst the other three velktes have engines of 24, 30, and 4o11,.p. (on numbers D26, E41,and F54, respectively). The first three en gines are fitted with a dual system of ignition in which a high-tension magneto is stipplemented by accumulator and coil. The large honeycomb radiator is of the type known as Meg-ever& patent; this is manufactured and handled in England solely by John Marston, Ltd., of Wolverhampton, for which company Mr. Leo Harris (the organiser of the recent meet of commercial motors at Reading) is the chief business representative.

From the engine to the gear-box, the power is transmitted through a leather-faced cone-clutch of large diameter which is., mounted in such a manner as to permit the male portion of the clutch to be easily removed, for the purpose of re-facing it with leather, without disturbing either the engine or the gearbox. The latter provides for three forward speeds, and one speed in a reverse direction. The third, or top speed is a direct-drive, when the lay-shaft is entirely disengaged. The changing of speeds is controlled from a hand-lever on the driver's right; this operates a single sliding rod and striking fork within the gear-box. The lay-shaft, on which the gear-wheels are fixed, is really a bushed-sleeve, revolving on a fixed spindle whose ends are supported in housings in the gear-box casting. The internal bearings of the sleeve are automatically lubricated, and the working of this box when the car is under load, is very silent. The main-shaft is of square section and on this the toothed-sleeve and direct-drive clutch slide; the shaft is mounted on " Hoffmann " ball-bearings, a double-thrust bearing being introduced in such manner as to relieve the journals of all lateral load due to changing gear. The introduction of a spring drive is another feature of all the Dennis vehicles. In this arrangement, the engine power is transmitted through four-coil or helical springs and the chief advantage claimed for it is that the gearing and back-axle are relieved of shocks due to the sudden release of the clutch or to any " fierceness " on the latter's part in action.

The back-axle, as already mentioned, is worm driven. The worm-gear is en_ closed in a malleable-iron casting, with ample, specially-strengthened, outer flanges into which the live-axle casings are screwed and locked. These casings are extended to take the bearings of the driving-wheels. These latter have star-shaped recesses cast in the hubs, and into these fit star pieces which are mounted on the squared ends of the divided-axle; the wheels are thus very easily removed and all keys or keyways on the axle are avoided. Further particulars regarding the measurements of these vehicles will be found in the table of particulars contained in our issue of the 22nd August last.

The advent of Dennis Brothers, Ltd., into the region of the 5-ton load will be noted with interest, as the company is one of those which seeks to challenge the steam wagon upon its merits. By the time the ,vehicle (No. F54) has reached Nottingham, after the experience of Lancashire and Yorkshire roads, it will have demonstrated its capacity in this direction.