1 MANY PLACES on a motor hicle it is necessary

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

to provide perfect seal between two )mponents to prevent gas, oil, ater or fuel leaking from beteen them. It is possible to achine two mating surfaces so :curately that one is such a )od fit on the other that no isket need be fitted between em.

This, however, would be exNisive and in some cases the Ones would not retain their :curacy, so it is common prac.to fit gaskets to prevent aks. Gaskets are made of a irly soft material so that they in be squeezed into any irreilarities in the two mating surces and so prevent leaks.

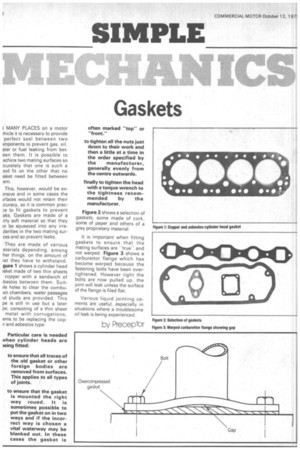

They are made of various aterials depending, among her things, on the amount of at they have to withstand. gure 1 shows a cylinder head isket made of two thin sheets copper with a sandwich of ibestos betw2en them. Suitle holes to clear the combuon chambers, water passages id studs are provided. This pe is still in use but a later pe, consisting of a thin sheet metal with corrugations, ems to be replacing the copitand asbestos type.

Figure 2 shows a selection of gaskets, some made of cork, some of paper and others of a grey proprietary material.

It is important when fitting gaskets to ensure that the mating surfaces are -true.' and not warped. Figure 3 shows a carburettor flange which has become warped because the fastening bolts have been overtightened. However tight the bolts are now pulled up, the joint will leak unless the surface of the flange is filed flat.

Various liquid jointing cements are useful, especially in situations where a troublesome oil leak is being experienced.