Holding Frame Brackets.

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

BRACKETS will sometimes become Loose on frames to such an extent that new bolts are necessary to hold them fast ; but even then there are cases where new bolts will not stop a bracket from working loose.

The same trouble is sometimes eiperienced with the flywheels of engines, which decline to hold firmly to their flanges.

Face keys are sometimes used to keep a flywheel firm on its flange, but it is extremely difficult to locate such keyways with the necessary accuracy that the keys can be relied upon to he a good fit, and unless they are a good fit they are useless.

" of Birmingham, has found a way of making face keys that can be relied upon for accurate fitting and yet ' can be applied to a frame or crank flange and flywheel while in place.

The two parts to be united are put together and tightly bolted no ; while in this form a small hole is drilled right through both parts. A hole of about diameter will do, and this can be drilled with a breast drill, The parts are then separated and the holes enlarged with a• pin-drill to .a convenient depth. A cheese-shaped piece is then turned to fit the hole made by the pin-drill and the parth reassembled; and there will be no more working loose. The pin-drill can be operated in a ratchet brace if no drillingmachine be available.

Removing Steering-arm Ball A. PRACTICAL hint to drivers and mechanics who find the removal of ball pins from the tapers. in steering arms a tough job is 'forwarded by "3.5.,'.. of Edinburgh, who describes how to rem* them without any fear of doing damage to the threads. Take a heavy crowbar and, Using a suitable fol. crum, 'apply Pressure to the end of the ball pin,while•a mate or apprentice taps the taper boss all round and then strikes a sharp blow downWards on the aim, when the pin will jump from the taper.

To Silence Undershields. A_LL those who have been troubled with rattling and drumming under-. shields will be interested in• the advice given by "LW.," of Wolverhampton„ which we give in hi s own words :— "A drumming iindershielcl is in nearly every instance due te weak staying or to the use of sheet metal of too light a gauge. The first thing is to tighten up all the bolts which hold the undershield in position, so that there can-be nepossi:' bility of rattle from this source.

" Attempts should be Made to find the place of vibration by running the engine until the drumming commences and then using a long stiff rod, such as a brush handle, which can be pressed against the undershield in different places until the noise stops. 'A stiff wooden batten can then be placed inside the undershield, from side to side, and fastened -by wOod screws from lnitside., This will generally effect a cure.

".In particularly bad cases it may * necessary to fix a struit of wood betwee. the 'bOttoin of the -crankcase and tip! tindershield. It should be ctitto a goat) tight-fit" andalsb seenredwood screws. A properly • deSigned.underi shield, evenof light-gatige -metal;Is strengthened and .stiffecied by•theane of suita-b/y, arranged •••–corrugations; . lit some-cases,inetaf stiffeners :are used," A Useful Mallet.

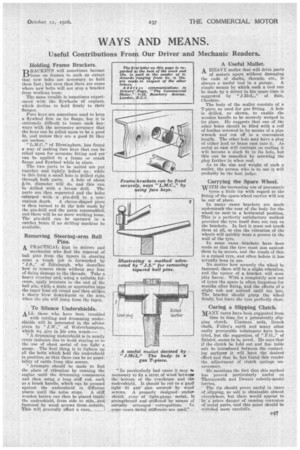

A HEAVE mallet that will drive parts

of motors apart without damaging the ends of shafts, threads, etc.. is always a "useful tool in a garage. A simple means by which such a tool can be made by a driver in his spare time is suggested by " J.McL.," of Sale, Cheshire..

The body of the mallet consists of a T-piece as used for gas fitting. A hole is drilled, as shown,. to enable the wooden handle to be securely wedged in its place. He suggests that one of the other holes should be filled with a coil of leather screwed in by means of a pipe wrench and cut off to a convenient length. The other hole may have a plug of either lead or brass cast into it. As metal so cast will contract on cooling it will become a slack fit in its hole, but this can be remedied by screwing the plug farther in when cool. • As to the size and Weight of such a mallet, the person who is to use it will probably be the best judge.

Carrying the Spare Wheel.wiTH the increasing use of pneumatic

tyres a little tip with regard to the fitting of the spare-wheel carrier will not be out of place.

In many eases brackets are made underneath the rear of the body for the wheel ,to rest in a horizontal position. This is a perfectly satisfactory method provided the tyre itself does not rest on the brackets. In fact it must not touch them at all, or else the vibration of the wheels will quickly wear a groove in the wall of the tyre.

In some cases -brackets have been made so that the tyre must jam against them to be secure, and the result of this is a ruined tyre, and often before it has actually been in use.

No matter how securely the wheel be fastened, there will be a slight vibration, and the corner of a bracket will soon Play havoc. With a completely new set of tyres the spare is often forgotten tor months after fixing, and the effects of a slight rub notnoticed until too 'late. The bracket should grasp the wheel firmly, but leave the tyre perfectly clear.

Curing a Slipping Clutch.

1MEANY cures have been suggested from

time to time for a persistently slipping clutch. Common sOda, french chalk, Fuller's earth and many other easily procurable Substances have been tried, bat the suggestion of " F.G.," of d Bristol, seems the novel'. He says that if the clutch be held out and fine table salt be introduced betWeen the contactin... surfaces it will have the desired elect and that he has found this render the adjustment Of clutch springs unnecessary.

He mentions the fact that this method has proved Particularly useful on Thorn,veroft and Dennis subsidy-model lorries.

The tip should prove useful in cases of slipping, assalt is obtainable almost everywhere, but there would appear to Ife'a grave danger of causing corrosion ottnetai parts, 'and this point should be watched most carefully,