DRIVING, STEERING AND BR ING ON ALL FOUR WHEELS.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Exclusive and Detailed Information Regan Which is Equally Suitable for Cross.

the Remarkable Holverta-Vulcan Chassis, Ltry and for High-speed Road Work.

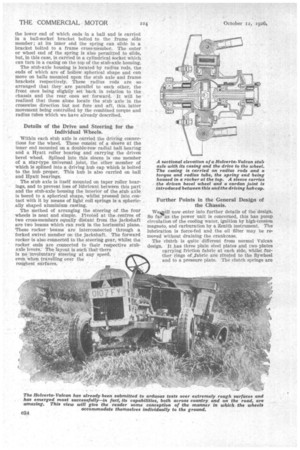

A TYPE of vehicle almost revolutionary in its design, but which arduous tests have shown to be perfectly practicable, has recently been built by the Vulcan Motor and'Engineering Co. (1906), Ltd., of Crossens, Southport. This new vehicle is known as the HolvertaVulcan and is a development from the Holle, the invention of a Belgian gentleman of that name, the experimental model of which was built by French's Motor Engineering Works, Ltd., of Balham, London, S.W., and which was described in detail in the issue of The Commercial Motor dated October 16th, 1923.

The Holverta-Vulcan, whilst embodying the main principles which were aimed at in the original design, I ears but little resemblance to its prototype. In fact, it has been redesigned throughout and has now become a commercial proposition, two examples being under construction for the African and Eastern Trade Corporation, Ltd., whilst a further two are being built as demonstration chassis.

Each will carry a net load of 1 ton in its own body and will haul a 30-cwt. turntable trailer of special deSign, these trailers, incidentally, being built by W. Tasker and Sons, Ltd., of Andover.

A Type of Vehicle Equally Suitable for Road or Cross-country Service.

The difficulties considered necessary to overcome are to produce a vehicle which will be as efficient as the creeper-track machine for traversing roadless country, whilst being even more efficient than the ordinary type of four-wheeled vehicle for use on the road. It has also been the aim of the designers so greatly to improve the spring suspension of the vehicle as to permit passengers to ride in complete comfort even on the roughest surfaces and at a fair speed, or, where passengers are not carried, to prevent damage both to the vehicle and its load. This matter is one of particular interest to us, as quite recently we have been devoting considerable space both in The Commercial Motor and in its associated journals to this question of improving vehicle suspension.

It has been recognized by the designers of this new chassis that a four-wheeled vehicle intended for crosscountry work must drive on all its wheels, and, to enhance its naanceuvrability, if should also steer on all wheels, but still more important is the employment of wheels which are permitted freedom of movement individually.

. From the point of view of suspension the ordinary axled vehicle cannot be looked upon as anything else than crude, and it is only where axles have been secured to the chassis in such a manner as to be given exceptional freedom of movement—as where crosssprings are employed, or, in the case of the six-wheeler, the semi-bogie arrangement—that vehicles have been able to traverse with success unusually rough roads and tracks; but, at its best, where a pair of wheels is joined together by an axle, movement of one wheel must have an unwanted effect on the other and there is almost certain to be considerable racking of the chassis frame, whereas if each wheel be permitted to rise and fall independently on its own spring it can follow the contour of the road with much greater freedom, whilst the unsprung weight can be reduced to an appreciable extent.

How Wheel-spin is Obviated and Road Adhesion

In our opinion, one of the most important causes of road abrasion and tyre wear is the wheel spin which occurs when a wheel leaves the ground while the vehicle is travelling, which spin has to be violently braked when the wheel again returns to the road surface. Where an axle does not have to be lifted, this bouncing of a wheel is much reduced; and, consequently, considerable saving in road and tyre wear should result. In addition, with four wheels driven in the manner adopted in the Hcilverta-Vulcan, spinning of c32 individual wheels cannot occur, as, to permit it, both wheels at one side of the chassis Would have to be clear of the road simultaneously, and, with the differential locked, even this would not permit the wheels to spin. There is another point in connection with a vehicle without axles ; that is, the high ground clearance which can be obtained, and this without unduly increasing the 'height of the platform. • Before giving a complete specification of this striking chassis, we will briefly describe its salient features. At first view, it might appear somewhat complicated, but when the points of the actual chassis are examined it is seen that it is very little more complicated than an ordinary type, and, what is more, the components are such that, if standardized and placed on a production basis, the price should not be greatly in excess of the standard type of chassis, considering the great advantages which accrue. Take, for instance, the frame; this is practically the same as would be employed in the ordinary course. It is perfectly straight in both planes, although tapered slightly to front and rear. It is substantially braced by channelsection cross-members, and has two special dropped cross-members, to which the lower radius rods of the stub-axle housings are pivoted.

The power unit, which, incidentally, is a standard 85 mm. bore by 130 mm. stroke Vulcan, with four cylinders cast en bloc, is carried in the usual position at the front, and built up as a unit with this is the multiple-disc clutch and four-speed gearbox, the whole being three-point suspended.

Distributing the Drive to Four Wheels Through a Single Differential.

In the centre of the frame is ,a jackshaft with overhead worm drive. it is connected to the gearbox shaft by an internally toothed coupling, which gives sufficient freedom of movement to conform with any possible distortion of the chassis.

Stretching in front of the jackshaf t. is a torque tube anchored at its forward end by trunnion bearings to a frame cross-member. The differential shafts of the jackshaft carry bevel pinions, but are further extended to take brake drums of special form. Each of the bevel pinions meshes with two others carried in a tribution box bolted to the frame side member, from which the drive is conveyed through shafts contained in combined torque and radius tubes to the front and rear wheels at one side. Each of these shafts includes a star-type cardan joint contained within its respective torque ball.

It will be noted that there is only the one differential —that in the jackshaft—so that the drive to the front and rear wheels on one side of a chassis is positively' Interconnected.

Two dog clutches are provided for the jackshaft differential. With both disengaged the extension of the worm shaft can be used as a power take-off for driving winch gears, etc. With one clutch engaged the drive is taken to the wheels through the differential, whilst with both clutches in action the differential is locked solid and no wheel can turn independently of the other three.

Brake Drums as Driving Wheels for Passing Over Abnormal Obstructions.

There is a hand-brake drum on the worm tailshaft. The other brake acts on the jackshaft brake drams to which we have already referred. A feature of these drums is that they are made of extra strength and, externally, they are moulded with strakes and can act as auxiliary driving wheels when the vehicle is travelling over a very steep hump-backed bridge or other abnormal obstruction where, in the ordinary course, the vehicle might fulcrum on its brake drums, and, consequently, lose wheel adhesion. These brakes, as well as the worm tailshaft brake, are a the internalexpanding type, and it is notable that the drums may readily be removed for relining the shoes without dismantling any other part, and in each case the cap nut Which secures the brake drum may be used as a tool for withdrawing the drum.

In connection with the use of brake drums as a means for driving the chassis, it is important to note that the peripheral speed of these drums is approximately the same as that of the tyres.

Each stub-axle housing has independent spring mounting by a cantilever spring splayed out across the chassis, each spring having for its fulcrum a pivot pin,

the lower end of which ends in a ball and is carried in a ball-socket bracket bolted to the frame side member ; at its inner end the spring can slide in a bracket bolted to a frame cross-member. The outer or wheel end of the spring is also permitted to slide, but, in this ease, is carried in a cylindrical socket which can turn in a casing on the top of the stuli-axle housing.

The stub-axle housing is located by radius rods, the ends of which are of hollow spherical shape and can move on balls mounted upon the stub axle and frame brackets respectively. These radius rods are so arranged that they are parallel to each other, the front ones being slightly set hack in relation to the chassis and the rear ones set forward. It will be realized that these alone locate the stub axle in the crosswise direction but not fore and aft, this latter movement being controlled by the combined torque and radius tubes which we have already described.

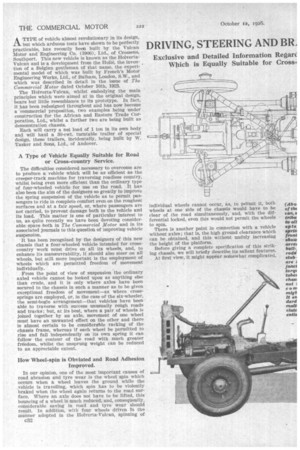

Details of the Drive and Steering for the Individual Wheels.

Within each stub axle is carried the driving connections for the wheel. These consist of a sleeve at the inner end mounted on a double-row radial ball bearing and a Hyatt roller bearing and carrying the driven bevel wheel. Splined into this sleeve is one member of a star-type universal joint, the other member of which is splined into a driving hub cap which is bolted to the hub proper. This hub is also carried on bail and Hyatt bearings.

The stub axle is itself mounted on taper roller bearings, and to prevent loss of lubricant between this part and the stub-axle. housing the interior of the stub axle is bored to a spherical shape, whilst pressed into contact with it by means of light coil springs is a spheric. ally shaped aluminium casting.

The method of arranging the steering of the four wheels is neat and simple. Pivoted at the. centres of two cross-members equally distant from the jackshaft are two beams which can rock in the horizontal plane.. These rocker beanis are interconnected through a forked swivel member on the jackShaft. The forward rocker is also connected to the steering gear, Whilst the rocker. ends are connected to their respective stubaxle levers.' The layout is such that there is no involuntary steering at any speed, even: whentravelling over the roughest stirfaces. '

Further Points in the General Design of the Chassis.

Weill now enter into further details of the design. So far as the power unit is concerned, this has pump circulation of the cooling water, ignition by high-tension magneto, and carburation by a Zenith instrument. The lubrication is force-fed and the oil filter may be removed without draining the crankcase.

The clutch is quite different from normal Vulcan design. It has three plain steel plates and two plates carrying friction fabric at each side, whilst further rings ofjabric are riveted to the flywheel and to a pressure plate. The clutch springs are of the coil compression type and are adjustable by external setscrews with lock-nuts. The spigot beating is a two-row radial ball race. This clutch is totally enclosed in a bell housing.

Four speeds and a reverse are provided by the gearbox. It has centre change and includes provision for the driving of a tyre pump and a mileometer. ,

The whole engine is three-point mounted in the frame, whilst the jackshaft is supported from the side members of the frame-by two trunnion bearings.

Any one of three ratios tif-Worrn gear can be provided, these being :-Low, 6 to 26 (or 4.333 to 1) ; medium, 6 to' 22 (or 3.666 to 1) ; high, 9 to 24 (or 2.644 to 1). It is notable that the distribution gears and the wheel-driving gears are all of the spiral-bevel type.. The distribution gears have an equal number of teeth, but the final reduction in the wheels gives a ratio of 9 to 20 and the totai ratios on top gear with the various worm ratios mentioned are:-Low, 9.63 to 1; medium, 8.15 to 1; high, 5.92 to 1.

The torque tubes are of solid-drawn steel tube, each being provided at one end with a flange for attachment to the stub-axle casing and at the other end with a spherical housing enclosing the Spicer-type universal joint for the propeller shaft. The ball joints for•the radius rods are a special type, consisting of a bronze ball fitting loosely on a crosspin, but carried as a running fit in the ball housings of the radius rods. This permits full movement in the vertical plane and quite sufficient in the horizontal plane. The total spring flexure or movement of each wheel is 8 ins., being 2 ins, below and 6 ins, above normal road level.

Dunlop pressed-steel wheels are employed, and these can be equipped with 35-in, by 5-in. or 37-in, by 6-in. Dunlop low-pressure tyres.

Egg-shaped rubber buffers are employed to check excessive wheel movement, and these come into action after the first 3 ins, of spring deflection. Check straps for rebound are also provided.

The principal dimensions of this remarkable chassis are :-Wheelbase, 9 ft. 6 ins.; track, 4 ft. 8 ins.; minimum .ground clearance below radius rods, 114 ins.; minimum clearance below foot-brake drums, 124 ins.; overall width, 6 ft. 2 ins.; overall length (including starting handle), 15 ft. 3 ins.; height of main frame, 2 ft. 3 ins.; distance from driver's seat to centre of rear wheels, 4 ft. 74 ins., or to rear of chassis 7 ft. 7 ins.; this latter dimension may be increased.