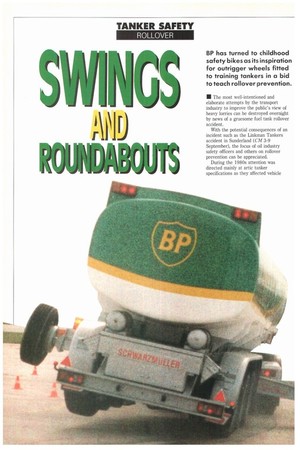

BP has turned to childhood safety bikes as its inspiration

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

for outrigger wheels fitted to training tankers in a bid to teach rollover prevention.

• The most well-intentioned and elaborate attempts by the transport industry to improve the public's view of heavy lorries can be destroyed overnight by news of a gruesome fuel tank rollover accident.

With the potential consequences of an incident such as the Linkman Tankers accident in Sunderland (CM 3-9 September), the focus of oil industry safety officers and others on rollover prevention can be appreciated.

During the 1980s attention was directed mainly at attic tanker specifications as they affected vehicle stability. Development of low-slung max cross-section designs was sponsored by vehicle builders such as Mercedes-Benz and oil companies like BP. Bringing down the centre of gravity of semi-trailer tanks improved roll stiffness when cornering and on adverse cambers. So too did the adoption of wider-centred suspension, with air bags instead of leaf springs.

But BP Oil's Brussels-based European distribution safety manager Dirk van Werkhoven says that such vehicle improvements are apt to give drivers a false sense of security. Corners and roundabouts will he negotiated more rapidly and/or with less care unless drivers are made aware of the hazards.

INSTINCTS

Studies by BP indicate that upgrading tractor cab and seat suspensions, among a host of improvements in truck refinement over the past decade, tend to insulate the driver from vehicle behaviour. Despite traditional seat-of-the-pants instincts he can be unaware of the beginnings of a rollover until it is too late.

BP has taken the initiative among the oil companies in setting up a Europe-wide driver training programme which targets artic tanker hazards, and rollovers in particular. What makes the BP training venture unique in the oil industry, at least, is its hands-on nature. A 2+3 MAN-hauled artic tanker made available by BP's Austrian distribution company has been fitted with simple (though hefty) wheeled outriggers attached to the tank just ahead of the tri-axle trailer bogie, which perform the same function as those on a toddler's bicycle.

In an eight-week programme, at eight airfield sites around the country, more than 350 of BP Oil's UK drivers have been able to get behind the wheel of the 40-tonne Austrian tank rig and push it to its cornering limits.

A series of manoeuvres are executed: at constant speed through progressively tighter corners; at gradually faster speeds through a given corner; and at different speeds and lines during change-of-lock roundabout simulations. "One object," says van Werkhoven, "is to make drivers realise that rollovers can he unwittingly induced at speeds as low as 15mph."

Articulation is the enemy of roll stability. As soon as tractor and trailer get out of line, the laws of dynamics which govern the cornering stability of a rigid vehicle start to lose their validity, as the vehicle's centre of gravity (as viewed from above) moves outwards.

Thanks to ABS anti-skid equipment, now standard on tractors and trailer bogies throughout BP's UK artic tanker fleet, rollovers caused directly by jack-knifing are today almost unknown. It was common practice in the past, points out van Werkhoven, for a driver seeking to avoid a collision at a road junction, to steer out of trouble rather than stamp on the brake pedal, for fear of jack-knifing.

But because such swerving aggravates the angle of articulation, it can all too easily lead to a rollover. The advice now is to "let technology take the strain" and brake as hard as possible, preferably without swerving. The ABS will prevent a jack-knife-induced rollover.

Lateral surge of liquid product in a tank, long thought to be a significant factor in causing roundabout rollover accidents, is largely dismissed by BP. Discharging of whole compartments minimises the side-to-side part-load "slosh" effect, though van Werkhoven concedes that in some situations it could be the last straw which pushes a teetering tank over.

Of more concern is the unstabilising effect of a partly offloaded tank, with some compartments full and others empty. The centre of gravity of a vehicle is at risk of being shifted forward during a series of deliveries — most obviously by emptying the rear compartments first — so that when the rig is negotiating a given-radius bend, the centre of gravity will also be shifted outwards.

If the forward compartments are emptied first, roll stability on bends is enhanced, but at the possible cost of traction because the share of all-up weight imposed on the drive axle is reduced. It is a snag which ASR anti-slip control could help solve.

ALARMS

Mike Baddeley, BP Oil's safety and legislation manager in the UK, his European counterparts, and Dirk van Werkhoven have given a lot of thought to the provision of alarms which would warn the driver of imminent loss of roll stability. But timing is a problem_ A laden tank can begin rolling over within two seconds of the trailer bogie tyres on the inside of the corner leaving the ground.

Thankfully public spiritedness overrules commercial inhibitions when it comes to safety. As the first oil company to instigate hands-on rollover avoidance training for drivers, BP is ready and willing to share its experiences and findings with its competitors. Already BP, Shell, Esso, Texaco and Petrofina have collaborated to produce a video.

Action to improve fuel tanker safety has also been taken by Wincanton Transport, whose oil industry contract clients include Texaco and Esso. Bernard Commons, WT's health, safety and quality manager, says a key training element in combating rollovers is to curb drivers' aggressiveness. if roundabouts and bends can be approached without any thought of "getting there before the other man", the abrupt changes in articulation angle and/or speed which can so easily lead to rollover conditions can be avoided.

Although BP's oil company rivals all run extensive tank driver training programmes, the rollover danger is dealt with essentially as a video-aided classroom instruction subject. In the spirit of Wincanton's non-aggressive approach, Shell says its instructors pay a good deal of attention to driver "psychology". And at two and five-year intervals Esso puts its tanker crews through minor and major refresher courses where emphasis is placed on "defensive" driving.

0 by Alan Bunting