odale snappy service

Page 79

Page 80

If you've noticed an error in this article please click here to report it so we can fix it.

DESPITE the reduction in environmental pressures to limit the use of large com mercial vehicles in urban areas, there is still a statutory duty locally to comply with the Heavy Commercial Vehicles (Controls and Regula tions) Act 1973 by January, next year. The full implementation of this has cost implications for the operator because it will inhibit use of trunk vehicles for the collection and delivery function.

Moreover, the possibility of the introduction of shorter driving hours will leave little time for the trunk driver to undertake the distribution of his load if he is involved in multiple drop operation.

Though these factors might encourage an operator to undertake only the trunk journey leaving the final delivery to be accomplished by a local operator, the present trend toward companies offering a complete door to door service might make this course unattractive.

It is more likely that operators will seek to provide their own local distribution transferring goods from the trunking vehicle to smaller units for this purpose.

There is really no need to provide elaborate depots to perform this service unless there is a need for absolute security; indeed, some operators are achieving transfers at motorway service areas. Costing the operation will of course have to incftide the handling costs involved and this will depend on the amount of sophistication involved.

As far as the vehicles themselves are concerned, there is no difference in technique in costing vehicles whatever their size and having discovered the daily cost of small vehicle operation the cost per drop is easily established by dividing the daily coast by the number of deliveries. For more detailed costing to enable an operator to charge on a per package basis, the daily cost can be divided by the number of packages carried.

Possibly, difficulty might be experienced where small vehicles are operating from a number of transfer points and it

might not be easy to keep track of vehicle costs at each of these places.

The distribution division of Kodak Ltd at Heme Hem pstead monitors its Ve icle costs through a centr I financial analysis division so that vehicle performance can e constantly monitored.

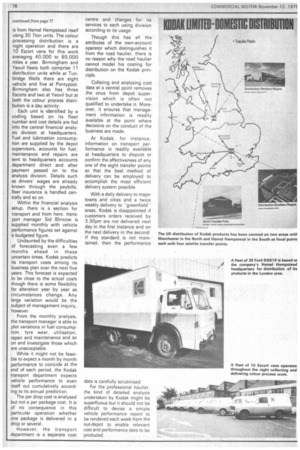

The company has divided the country into two for distribution purposes. With distribution points at Manchester and Hemel Hempstead there is a constant intercha ge of products between t ese centres using 32ton rtics interchanging trailers. It seemed logical, therefore, to establish transfer points wit Manchester and Hemel Hempsltead as focal points.

In the North, sirfnple transfer points have been efstablished at Glasgow, Gateshe d and Leeds and in the South at Birmingham, Tunbridge Wells, Yeovil and Pontypool.

These are not stock holding depots but compr se comparatively inexpensi e covered accommodation ijoder which products can be transferred between trunker nd distribution vehicle and I ads consolidated for back ioa91 Each transfer ing. oint has its own small vehicl fleet corn7 ton rigids prising a mixture o and 35cwt Transi s and some have 8cwt Esco vans for Ilection and colour process c delivery. Taking he southern area as an exampl , distribution continued overleaf is from Hemel Hempstead itself using 30 7ton units. The colour processing distribution is a night operation and there are 10 Escort vans for this work averaging 40,000 to 60,000 miles a year. Birmingham and Yeovil fleets both comprise 11 distribution units while at Tunbridge Wells there are eight vehicle and five at Pontypool. Birmingham also has three Escorts and two at Yeovil but at both the colour process distribution is a day activity.

Each unit is identified by a coding based on its fleet number and cost details are fed into the central financial analysis division at headquarters. Fuel and lubrication consumption are supplied by the depot supervisors, accounts for fuel, maintenance and repairs are sent to headquarters accounts department direct and after payment passed on to the analysis division. Details such as drivers wages are already known through the paybills, fleet insurance is handled centrally and so on.

Within the financial analysis setup, there is a section for transport and from here, transport manager Sid Blincow is supplied monthly with vehicle performance figures set against a budgeted figure.

Undaunted by the difficulties of forecasting even a few months ahead in these uncertain times, Kodak predicts its transport costs among its business plan over the next five years. This forecast is expected to be close to the actual costs though there is some flexibility for alteration year by year as circumstances change. Any large variation would be the subject of management inquiry, however_ From the monthly analysts, the transport manager is able to plot variations in fuel consumption, tyre wear, utilisation, repair and maintenance and so on and investigate those which are unacceptable.

White it might not be feasible to expect a month by month performance to coincide at the end of each period, the Kodak transport department expects vehicle performance to even itself out cumulatively according to its annual prediction.

The per drop cost is analysed but not a per package cost. It is of no consequence in this particular operation whether one package is delivered in a drop or several.

However, the transport department is a separate cost centre and charges for its services to each using division according to its usage.

Though this has all the attributes of the own-account operator which distinguishes it from the road haulier, there is no reason why the road haulier cannot model his costing for distribution on the Kodak principle.

Collating and analysing cost data at a central point removes the onus from depot supervision which is often not qualified to undertake it. Moreover, it ensures that management information is readily available at the point where decisions on the conduct of the business are made.

At Kodak, for instance, information on transport performance is readily available at headquarters to dispute or confirm the effectiveness of any one of the eight transfer points so that the best method of delivery can be employed to accomplish the most efficient delivery system possible.

With a daily delivery to major towns and cities and a twice weekly delivery to -greenfield' areas, Kodak is disappointed if customers orders received by 3.30pm are not delivered next day in the first instance and on the next delivery in the second. If this standard is not maintained, then the performance

data is carefully scrutinised.

For the professional haulier, the kind of detailed analysis undertaken by Kodak might be superfluous but it should not be difficult to devise a simple vehicle performance report to he rendered each week from the out-depot to enable relevant cost and performance data to be produced.