A New Refuse Trailer for Power Operation

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

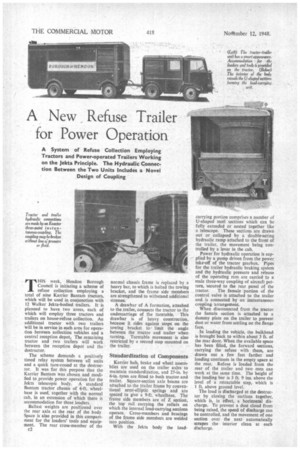

THIS week, Hendon Borough Council is initiating a scheme of refuse collection employing a total of nine Karrier Bantam tractors, which will be used in conjunction with 12 Walker Jekta-bodied trailers. It is planned to have, two areas, each of which will employ three tractors and trailers on house-refuse collection. An additional tractor with two trailers will be in service in each area for operation between collection vehicles and a central reception depot. The remaining tractor and two trailers will work between the reception depot and the destructor.

The scheme demands a positively timed relay system between all units and a quick turn-round at the destructor. It was for this purpose that the Karrier Bantam was chosen and modified to provide power operation for the Jekta telescopic body. A standard Bantam tractor chassis of 6-ft. wheelbase is used, together with the normal cab, in an extension of which there is accommodation for three loaders.

Ballast weights are positioned over the rear axle at the rear of the body Space is also provided in this compartment for the loaders' tools and equipment. The rear cross-member of the c2 normal chassis frame is replaced by a heavy bar, to which is bolted the towing bracket, and the frame side members are strengthened to withstand additional stresses.

A drawbar of A formation, attached to the trailer, connects the tractor to the undercarriage of the tUrntable. This drawbar is of heavy construction, because it rides against stops on the towing bracket to • limit the angle between the tractor and trailer when turning. Turntable movement is also restricted by a second stop mounted on the trailer.

Standardization of Components

Karrier hub, brake and wheel assemblies are used on the trailer axles to maintain standardization, and 27-in. by 6-in. tyres are fitted to both tractor and trailer. Square-section axle beams are attached to the trailer frame by conventional semi-elliptic springs and are spaced to give a 9-ft. wheelbase. The frame side members are of Z section, the top rail carrying the rollers on which the internal load-carrying sections operate. Cross-members and bracings of the frame side members are welded into position.

With the Jekta body the load carrying portion comprises a number of U-shaped steel sections which can be fully extended or nested together like a telescope. These sections are drawn out or collapsed by a double-acting hydraulic ramp attached to the front of the trailer, the movement being controlled by a lever in the cab.

Power for hydraulic operation is supplied by a pump driven from the power take-off of the tractor gearbox. Pipes for the trailer hydraulic braking system and the hydraulic pressure and release of the operating ram are carried to a male three-way coupling of aircraft pattern, secured to the rear panel of the

tractor. The female portion of the control valve is attached to the trailer and is connected by an instantaneous coupling arrangement.

When disconnected from the tractor the female section is attached to a dummy plate on the trailer to prevent dust or water from settling on the flange face.

In loading the vehicle, the bulkhead is brought back to within about 3 ft. of the rear door. When the available space has been filled, the forward sections, carrying the refuse with them, are drawn out a few feet farther and loading continues in the empty space at the rear. Refuse is loaded from the rear of the trailer and two men can work at the same time. The height of the loading bar is 3 ft. 9 ins, above the level of a retractable step, which is I ft. above ground level.

The load is discharged at the destructor by closing the sections together, which is, in effect, a horizontal discharge. To prevent a dust cloud from being raised, the speed of discharge can be controlled, and the movement of one section over the next automatically scrapes the interior clean at each discharge.