The Trend of

Page 211

Page 212

Page 213

Page 214

If you've noticed an error in this article please click here to report it so we can fix it.

ENGINE DESIGN

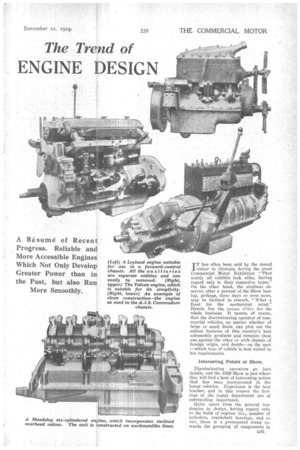

IT has often been said by the casual visitor to Olympia during the great Commercial Motor Exhibition "That nearly all exhibits look alike, having regard only to their respective types." On the other hand, the studious' observer, after a perusal of the Show lasting, perhaps, three days or even more, may be inclined to remark, "What a feast for the mechanical mind." Herein lies the raison d'are for the whole business. It means, of course, that the discriminating operator of commercial vehicles, no matter whether of large or small fleets, can pick out the salient features of this country's best automobile products and compare theta one against the other or with chassis of foreign origin, and decide—on the spot —which type of vehicle is best suited to his requirements.

Interesting Points at Show.

Discriminating operators go into details, and the 1929 Show is just where they will find a host of interesting points that has been incorporated in the latest vehicles. Experience is the best teacher, and in this respect the findings of the repair department are of outstanding importance.

Quite apart from the general tendencies in design, having regard only to the build of engines (i.e., number of cylinders, crankshaft bearings, and so on), there is a pronounced trend towards the grouping of components in such a manner that faulty parts can be removed quickly and easily and replaced by a spare or new component in a minimum of time, so that the vehicle can be kept on the road almost eontinnally. .

The lot of the maintenance engineer is becoming easier, for such regular jobs as decarbonization, valve grinding, etc.,. have obviously been considered when first planning the engine, and although overhead valves a r e becoming increasingly popular there can be no question but that the work entailed in lifting the cylinder heads, even of large engines, is nowadays very much less than in the past with comparatively small engines.

So much for the general outline ; we can now turn to details. In the first place, we will deal with the general build of modern power units. The multi-cylindered engine is gradually, but very surely, gaining ground. The " six " is now almost (.442

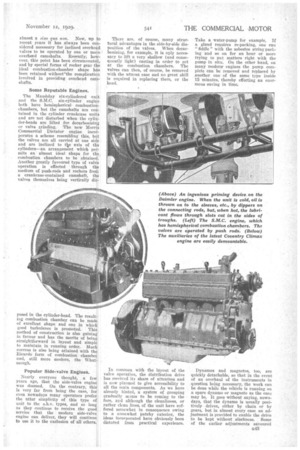

universally employed for vehicles engaged on long-distance work, and even in large buses it seems slowly to be gaining in popularity:. The eightcylindered engine has made its appear

once in America, and is incorporated in a chassis which is being marketed here by a British company.

The increase in the number of cylinders has, of course, made for smoother running, and in most cases greater power, but there are ,many Contributory causes to this state of affairs. For example, a six-throw crankshaft, although naturally much longer than a "four," is nowadays remarkably free from the had effects of torsional vibration, because the shaft • itself has been greatly increased in size (and consequently strengthened), despite the fact that the number of impulses per revolution has been increased and the individual loads decreased. This has brought with it another feature well worthy of comment -the enlarged crankshaft has, of course, larger journals so that the surface loads are all much smaller than they used to be. Add to this the fact that the crankcase, as a structure, is now considerably more rigid that in old-type engines, and one gets some idea of the reason why a modern power-unit will run many thousands of miles with only occasional " top" overhauls.

One of the biggest claims made by the sponsors of modern engines is that their products are now thoroughly efficient in the thermal sense, and no doubt credence must be given to such claims. Some of the latest types of vehicle are powered by units which vie for efficiency with some of the best sporting cars (as distinct from racing, cars, of course), and on a ton-mile-per-gallon basis for fuel consumption, show up to very great advantage. As with everything else, there is a great number of causes contributory to this halcyon state of affairs not the least being tat great attention has been paid to "combustion chambe r shape." Some experts consider that a hemisphere is about the best possible shape for a combustion head, and a number of designs has been evolved to achieve this form. Save for the sleeve-valve type of engine—as exemplified in the Daimler—inclined overhead valves are

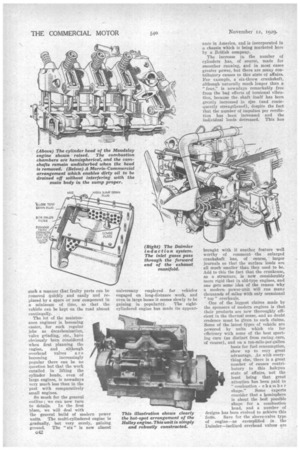

almost a sine qua non. Now, up to recent. years it has always been considered necessary for inclined overhead valves to be operated by one or more overhead camshafts. Recently, however, this point has been circumvented, and by special forms of rocker gear the ideal combustion-chamber shape has been retained without`the complication involved in providing overhead camshafts.

Some Reputable Engines.

The Maw Islay six-cylindered unit and the S.M.C. six-cylinder engine both have hemispherical combustionchambers, but the camshafts are contained in the cylinder crankcase units and are not disturbed when the cylinder-heads are lifted for decarbonizing or valve grinding. The new Morris Commercial Dictator engine incorporates a scheme resembling this, but the valves are all carried at one side and are inclined to tV axis of the cylinders—an arrangement which permits an almost ideal shape for the combustion chambers to be obtained. Another greatly favoured typo of valve operation is effected through the medium of push-rods and rockers from a crankcase-contained camshaft, the valves themselves being vertically dis posed in the cylinder-head. The resulting combustion chamber can be made of excellent shape and one in which good turbulence is promoted. This method of construction is also gaining in favour and has the merits of being straightforward in layout and simple to maintain in running order. Much success is also being attained with the Ricardo' form of combustion chambei and, still more modern, the Whatmough.

Popular Side-valve Engines.

Nearly everyone thought, a few years ago, that the side-valve engine was doomed. On the contrary, this is very far from being the case, for even nowadays many operators prefer the utter simplicity of this type of unit to the o.h.v. types, and so long as they continue to receive the good service that the modern side-valve engine can deliver, they will continue to use it to the exclusion of all others.

T,here are, of course, many structural advantages in the side-by-side disposition of the valves. When decarbonizing, for example, it is only necessary to lift a very shallow (and consequently light) casting in order to get at the combustion chambers. The valves can then, of course, be removed with the utmost ease and no great skill is required in replacing them, or the head.

In common with the layout of the valve operation, the distribution drive has received its share of attention and is now planned to give accessibility to all the main components. As we have already hinted, a system of grouping gradually seems to be coming to the fore, and although the cleanliness, or _rather clean lines, of the unit have suffered somewhat in consequence owing to a somewhat patchy exterior, the ideas incorporated have obviously been dictated from practical experience. Take a water-pump for example. If a gland requires re-packing, one can " fiddle" with the asbestos string packing and so on for art hour or more trying to put matters right with the pump in situ. On the other hand, on many moderir engines the pump complete can be removed and replaced by another one of the same type inside 15 minutes, thereby effecting an enormous saving in time.

Dynamos and magnetos, too, are quickly detachable, so that in th_e event of an overhaul of the instruments in question being necessary,the work can be done while the vehicle is running'on a spare dynamo or magneto as the ease may be. It goes without saying, nowadays, that the dynamo is usnally positively driven, either by chain or by gears, but in almost every case an adjustment is provided to enable the drive to be kept without slackness. Some of the earlier adjustments savoured very much of a .makeshift nature, but now operators are insistent that the parts concerned can be got at reason-, ably easily and an adjustment effected without having to dismantle a whole lot of adjacent details. There are, of course, many designs where the dynamo and magneto are in tandem, and the dynamo platform is so constructed that it will accommodate the magneto in the event of the failure of the former instrument. The dynamo then can be removed, possibly during the day when no. lights are required, be inspected, repaired and replaced on the vehicle for the evening—a great consideration in these busy times.

Last, but by no means least, we come to the lubrication system ; it is doubtful whether any single item in the makeup of an engine is quite so important. First, reliability is an absolute essential—failure m a y inean the ruination of an engine in less than a minute, whilst the absence of proper filtering arrangements may mean that the engine may be ruined comparatively slowly, but within a few thousand miles nevertheless.

Although conditions nowadays are altogether different from what they were only a few years ago, there is still room for further improvement, as is exemplified by the fact that concerns manufacturing auxiliary filters are in existence and are doing excellent business. The oil cannot he kept too clean, for under. modern conditions it is worked very hard.

As might be expected the more modern designs are really the best equipped in so far as filtering arrangements are concerned. In some engines there are no fewer than four filters, one enclosing the oil in the sump, another around the intake for the pump, a third in the pressure supply line and the fourth an auxiliary whieh deals with a by-passed flow of lubricant and extracts the minute particles which have passed through the other three filters. All this, of course, has a great effect upon the life of the bearings, pistons, cylinders, valve gear, etc., and as it reduces the rate of wear, the engine operates silently for a longer time than would be the case were filtering arrangements dealt with in a haphazard way.

One comparatively recent development is the incorporation of a " sludgetrap " in the sump. Many operators

feel that to drain the whole conten-ts of the sump (perhaps three gallons of oil) at regular intervals of 2,000 miles means the loss of a considerable amount of lubricant if taken on a yearly basis with a fleet of vehicles. Instead, a number of engines now has all the oil (which drains from the crankcase) directed into a small compartment in the main sump—having a capacity for perhaps half a gallon— with a weir incorporated between the trap and the main compartment. As the oil has to flow over the weir in order to reach the main pump, any contained dirt is inclined to sink to the bottom of the trap and remain there. The sum total of this arrange

meat, of course, is that when the trap is drained half a gallon of oil is lost; but other things being equal, it should be by far the dirtiest quantity.

There seem to be two distinct schools of thought regarding the layout for the piping of the lubrication system, some makers deeming it advisable to keep as much as possible disposed externally, whilst others wish to avoid altogether the use of pipes. These are, of course, advantages to be claimed for each method of construction. External piping allows everything to be dismantled quickly, a spare set of pipes fitted and the vehicle to be on the road again in a minimum of time the old Pipes being Cleaned at leisure. On the other hand, manufacturers who studiously avoid the use of pipes altogether, claim that at least one malevolent feature is entirely removed—the possibility of a breakage of one of the pipe-lines. Certainly engines look cleaner when they incorporate cast-in pipes or passages, but there is, of course, a certain amount of trouble involved in cleaning out the supply lines. This is an operation that can, of course, be carried out when overhauling becomes necessary—an infrequent occurrence.

The great improvement in filtering arrangements has, of course, had a bearing on this controversial point.

Summing up, therefore, one comes to the conclusion that the 1929 Show— so far as engines are concerned—indicates that the insistent demands of operators have been seriously considered by manufacturers. Maintenance work has been the chief item upon which great care has been expended in order to make everything as simple and straightforward as possible for the operator. Realization has at last been made of the fact that the operator's great maxim is to keep his vehicles on the road doinguseful work, and manufacturers are now doing all they can to help the user in this endeavour.