THE 100-TONNER Ready for the Road

Page 204

Page 205

If you've noticed an error in this article please click here to report it so we can fix it.

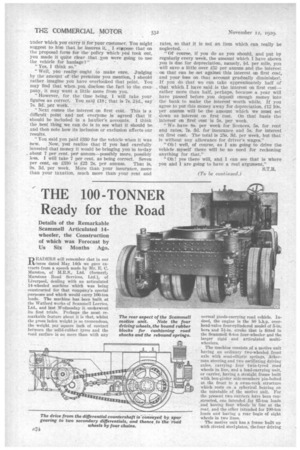

Details of the Remarkable Scammell Articulated 14wheeler, the Construction of which was Forecast by Us Six Months Ago.

RFADERS will remember that in our issue dated May 14th we gave extracts from a speech made by Mr. F. C. Marston, of MRS., Ltd. (formerly Marstons Road Services, Ltd.)., of Liverpool; dealing with an articulated 14-wheeled machine which was being constructed for that company's special purposes and which would carry 100-ton loads. The machine has been built at the Watford works of Scammell Lorries, Ltd., and last Wednesday it underwent its first trials.. Perhaps the most remarkable feature about it is that, whilst the gross laden weight is so tremendous, the weight per square inch of contact between the solid-rubber tyres and the road surface is no more than with any

normal goods-carrying road vehicle. Indeed, the engine is the 80 b.h.p. overhead-valve four-cylindered model of 5-in.; bora and 5i-in stroke that is fitted in the Seammell El-ton four-wheeler and the larger rigid and articulated multiwheelers.

The machine consists of a Motive unit having an ordinarytwci-wheeled *front axle with semi-elliptic springs; Ackerman steering and two oscillating driving axles, parrying tour twin-tyred road wheels in line, and a load-carrying unit, or carrier, having a straight frame built with box-girder side-members pin-bolted at the frontto a swan-neck structure which rests on a spherical bearing on the turntable of the motive unit. For the present two carriers have been constructed, one intended for 05-ton loads and having four wheels in line at the rear, and the other intended for 100-ton loads and having a rear bogie of eight Wheels in two lines.

The motive unit has a frame built up with riveted steelplates, thefonr driving

wheels of which are carried on two short axles, • these being free to oscillate upon longitudinal lever s, trunnionmounted at the forward end and supporting the frame at the rear end through the medium of large cylindrical rubber blocks. These constitute the only t springing of the driving wheels, the recoil being taken by two coil springs behind the rubber blocks, which operate in tension.

The Transmission System.

The engine and normal four-speed gearbox are carried in a sub-frame, from which the drive is taken by spiral-bevel gear to a differential countershaft. From each end of the countershaft the Dower is transmitted through spur gearing (incorporating a two-ratio variable gear) to a secondary differential, from 'which it is conveyed to the road wheels 'by two single-roller chains. The total tractive effort in the final stage is thus divided between four chains. Eight forward-gear ratios are provided, the secondary .gear change being controlled by a lever in the cab.

.Dealing.now with the trailing wheels of the carrier, in the case of the 05-tonner a forged-steel cross-member carries two rearward-projecting trunnions, en each of-which is mounted a pair of

wheels on an , axle. These axles are free to swive on a vertical axis, so that they can be steered through a screw-and-nut gear, turned by a large hand wheelwhich is under the control of a man riding on a platform at the rear, end of the machine. In the case of the 100-tonner, four more wheels on two short oscillating axles are fitted to the front ends of the trunnion forgings, these forgings being then allowed to oscillate on the centrally disposed crossmember, thus forming two four-wheeled bogies, each supporting one side of the main frame. They divide the load equally and are free to conform to the camber of the road. The steering of the rearmost wheels is still possible with the 100-tormer, the forward line being fixed.

Naturally, the question of brakinebas demanded careful consideration. A transmission brake, which has the benefit of the very -low gear and, therefore, calls for, little effort, can be operated by a pedal or. a small hand lever, the latter being useful when re-starting the machine on a hill. It is claimed that, without any great effort, the driver can hold the vehicle with this hand lever on a 1-in-10 gradient. There is also a handoperated screw brake which affects the driving -wheels; in addition, all the wheels of the carrier have internal-expanding brakes, these being actuated through a band wheel by the man riding on the rear platform. This man is kept in communication with the driver through a loud-speaking telephone of the Alfred Graham Admiralty type.

Needless to sayVthe -question of ground clearance when passing over small bridges is a difficult one.

It has been stated above that the swan-neck is held to the carrier frame by two pivot pins and it should be added that adjustable hydraulic-ram struts connect the swan-neck structure to the carrier frame. By operating a large double-cylindered, flywheel hand pump, these, struts may be extended, causing the swan-neck to -turn about the pins and raise the front end of the carrier

approximately 1 ft. 3 ins., thereby adding about 8 ins, to the ground clearance at the frame centre.

Alternatively, by releasing the oil pressure in the 'struts the front end of the carrier may be lowered about 1 ft., this causing a 6-in, drop in the centre of the carrier frame.

Driving Wheels Can be Lifted.

On the hydraulic-ram screws are jack nuts which take the load when the vehicle is running and which can be revolved by ratchet spanners to give a pulling action. Should the driving wheels sink into soft ground, sleepers may be placed under the front end of the carrier frame and by means of tbe ratchets the driving wheels may be lifted clear of the ground, to be replaced after the surface has been made good by laying down a boiler plate or by other means.

Should it be necessary to dismount the load from the front end, the swanneck may be disconnected and drawn away, after putting a pair of wheels on the ends of an axle permanently fixed to it. Alternatively, and without the use of any loose jacks, the rear-wheel assembly may be removed to permit unloading from the back.