Dereco examines latest diesel developments

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

RATIONALISATION seems to be the name of the game in the commercial vehicle manufacturing industry at present. There is General Motors with its world truck project Volvo, Renault and Daimler-Benz are crossing the Atlantic in search of a new market for European-designed products. There is already plenty of evidence of US engineering in Europe, and hardly a week passes without yet more news of joint ventures such as Rockwel1/Iveco, Dana/LF or Cummins/Leyland.

All this might lead one to suppose that choice of specification for the operation was being relentlessly narrowed. In general terms that might be so, but as far as engineers' designs for top weight vehicles are concerned there is still choice aplenty, and there are some significant differences between European and American thinking.

That is made clear in some recent research by Dereco (Die

sel Engine Research and Engineering Company) of Arbon, Switzerland. It examined development trends of European lorry diesel engines and, while it was concerned particularly with lubricant related trends, many of the comparisons should be of general interest to both operating and manufacturing engineers.

Legislation is clearly one of the major factors in determining which engine suits which market. As the accompanying tristogram shows, even among EEC countries which are aiming for • harmonisation, legislation concerning maxfrnum weights and Minimum power to weight ratio continues to vary a lot.

The same is true of speed limits, though the recent Changes in Britain have put us slightly Foss out of step. With regard to exhaust emissions, it is clear that a greater degree of harmonisation already exists in

most European countries (accepting the smoke limit according to EEC regulations) but there are currently no regulations concerning diesel engine gaseous emissions.

Noise emission standards, existing and proposed, seem to be the bane of every manufacturer's life and certainly figure in every engine manufacturer's research and development programme. The accompanying chart shows how the limits have been and are being lowered in different countries.

Everyone is looking for better fuel economy. Dereco notes some of the methods being used – low rated engine speeds, high torque rise, maximum torque at low engine speed, and the use of lower viscosity multigrade engine oils (generally 15 W 40). According to the Dereco report, fuel consumption of a 38 tonne gross combination weight vehicle on European motorways varies between 32 litre/100km (8.8mpg) with very economical driving and 44 litre/100km (6.5mpg) with fast, uneconomical driving. CM's road test results agree substantially with those figures.

In an interesting and detailed comparison of 21 European engines some clear European preferences are apparent. Only one, a Rolls Royce, is British, reflecting poor sales success of our manufacturers with engines rated between 206 and 309kW. All of the engines are four-stroke (Detroit Diesel Allinson knows how difficult it is to sell twostroke diesels in Europe). Most are turbocharged with compression ratios varying between 14 and 17:1, while the few naturally aspirated engines' compression ratios vary between 16 and 17.5:1. In most of the engines the bore/stroke ratio is less than one and, not surprisingly, the favourite configuration seems to be an in-line six, though, as the table shows, there is a good selection of V8s.

Dereco defines high speed power (HSP) as the power at an engine speed of 75 per cent of the rated speed, and low speed power (LSF') as the power at 50 per cent of the rated speed. It compares those of current engines with units made about five years ago to show how both HSP and LSP have increased "remarkably."

In diagram 1 and 2 it may be seen how power and torque ratings are predicted to continue rising in the next 10 years.

The reduction in rated speed which has occurred over the past few years is described as having good and bad points. Negative effects are related to "usable full load driveability" and exhaust brake performance,

while improved fuel economy and longer engine life owing to fewer revolutions are the advantages. Apart from reducing friction losses, a lower-rated speed also makes those ubiquitous noise regulations easier to meet.

On the engine oils, Dereci indentifies a number of significant differences between North America and Europe, which is interesting since North American lubricating oil standards are also in use in Europe. The oil loading, expressed in kW/litre oil capacity, is much higher on European engines. This is given as one of the reasons why European oil drain intervals are shorter.

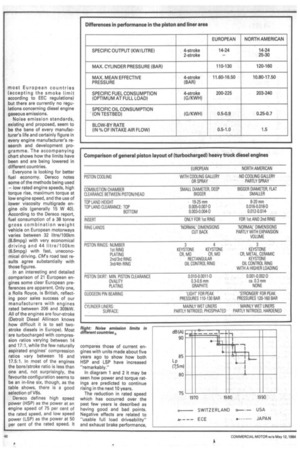

Other reasons for this are relatively low oil consumption (0.51.5 litre/1,000km with a maximum acceptable of 4 litre/1,000km), larger engine temperature changes, fuel dilution resulting from short distance operation and, in some cases, the effects of bore polishing. Figures 5 and 6 show

some importance differences, particularly in pistons and cylinder liners between typical European and North American engines.

American engines operate at higher maximum cylinder pressures. Their pistons' top land height is substantially smaller and top land clearance two to four times greater than in

European engines. A small top land clearance can cause the formation of hard-pressed carbon deposits, says Dereco, but the "tight" top land design is nevertheless adopted because the smaller dead volume results in better engine operating characteristics. On Cummins' latest 14 litre derivative, the Super E320 (described in CM, March 31

the top ring has been raised to reduce dead volume and improve fuel consumption.

Most European manufacturers try to keep maximum ring groove temperature around 215230°C by oil cooling by spray or gallery. Charge cooling can reduce top ring temperature by 1015°C, assuming power output is not increased, as well as reducing the thermal loading of other engine components.

What of the future? Dereco's engineers, like many others, are in no dount that legislation will play an increasingly significant role in determining engine design. The expected European diesel engine exhaust emission standards are: Unburnt hydrocarbons HHHHHHHHHHHHH C 3.5g/kWh Carbon monoxide 0 14g/kWh Nitrous oxide NN OX 18g/kWh These will require careful combustion matching and "possibly influence piston design," says the Dereco report.

Encapsulation is seen as the only means of complying with stringent noise emission limits, which themselves are expected to encourage further reductions in rated speed.

Efforts to improve fuel consumption are expected to be concentrated in four areas: a reduction of mechanical losses, improvement of engine performance between low and high speed power, electronic fuel injection, and lower viscosity lubricants with fuel efficiencyimproving additives.

In the short term more is going to be demanded of engine oils with higher brake ??? effective pressures, higher thermal loadings, probably higher peak cylinder pressures, and a higher oil loading (kW/litre oil capacity). But in the longer term even more is likely to be asked of engine oils if the adiabatic turbo compound engine goes into production as is predicted.

"Insulating the cylinder by means of ceramic components, or air gap will cause much higher temperatures at the piston and liner and these will lead to severe lubricating problems," warns the report.