:ontrolling engine emperature, 4

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

I THE previous articles, )ntrolling temperature by eans of a thermostat was oked at. Now the design of irious types of fans will be scussed.

Fans, driven by a "V" belt off a alley on the crankshaft to ipplement the flow of air past le radiator fins, are almost a iiversal fitting to modern thicles. A fan of this type for e vast majority of its working e will move a considerably rger amount of air than is ?cessary, at the expense of fuel msumption and noise. When le forward speed of the vehicle high, the air flow over the Idiator is sufficient to provide I the cooling that is necessary; Id the power the engine is roviding, to drive the fan, is asted.

One solution to this problem is dispense with the

mventional belt-driven fan and I replace it with an electric one rawing its current from the 3hicle's battery. Kenlowe, of laiden head, which has kindly applied me with information on ;products, offers electric fans ith blades up to 20 inches

diameter, for most trucks and coaches from three to 30 tons.

With the Ken lowe heavy duty thermomatic fan system, a thermo-sensor is fitted into the cooling system. It is possible to do this without drilling or making any other modifications, by using a patent rubber seal at the water hose, as Figure 1 shows.

A variable temperature control (20° to 120°C) allows the optimum "cut in" temperature for each application (The temperature control is also shown in Figure 1). A secondary back up sensor, located in external contact with the radiator tank, is set as a safety back-up to switch the fan on and provide a high temperature warning in the cab.

A facia indicator and manual switch is supplied but a safety bridge in the circuit precludes switching the fan off if the automatic temperature sensor has been pre-set to operate the fan. If required by the operator, the secondary sensor can be wired to a high-temperature warning light or buzzer or to an engine cut out device. The 20-inch-diameter fan takes 30 amps at 24 volts, which may be considered to make a fairly high demand on the battery but present day alternators should have no trouble in coping with this discharge, and in any case the fan is unlikely to be running for long periods. It is claimed that a fuel saving of up to 10 per cent can be achieved by use of a fan of this type. An additional bonus is the fact that when the fan is not in use, cab-noise levels will be reduced.

On passenger cars and light commercial vehicles torquelimiting viscous drives are sometimes fitted to fan drives. The viscous drive, operating as a shear-type fluid coupling, controls the fan speed by transmitting the drive through a film of silicone fluid. The dimensions of the fan drive and viscosity of the silicone fluid determine the torque transmitted and hence the fan speed.

In operation, the fan speed increases with engine speed, though at a lower rate, until the limit of torque capacity is reached. At this point the fan is operating at its maximum speed, which will not be exceeded when the engine speed increases further.

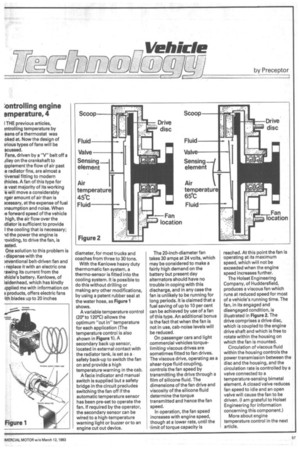

The Holset Engineering Company, of Huddersfield, produces a viscous fan which runs at reduced speed for most of a vehicle's running time. The fan, in its engaged and disengaged condition, is illustrated in Figure 2. The drive comprises a drive disc, which is coupled to the engine drive shaft and which is free to rotate within the housing on which the fan is mounted.

Circulation of viscous fluid within the housing controls the power transmission between the disc and the housing, and the circulation rate is controlled by a valve connected to a temperature-sensing bimetal element. A closed valve reduces fan speed to idle and an open valve will cause the fan to be driven. (I am grateful to Holset Engineering for information concerning this component.) More about engine temperature control in the next article.