Pressure to stop slides..

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

by John Hartley

SUDDENLY, anti-skid systems manufacturers try to overcome systems in the USA following No one doubts the value of an anti-skid system as a safety device, but many people are concerned about reliability— especially since, at £300-£400 per axle, the equipment is not cheap. For this reason, the British manufacturers are generally busy accumulating experience of the systems applied to driven axles of tractive units only.

One system that has come into contention quietly is the Bendix Westinghouse Electronic Braking Corrector (EBC). As reported (CM February 20) one of these units has been in use on a Guy Big J tractor operated by BRS (Midland) for 18 months, while 40 other units have now been fitted to other NFC vehicles. More than half of these have been in use for about six months—on Guy and Scammell tractors—and the last should be fitted out this week. NF1C has also had a Girling Skidchek fitted to a Guy Big tractor, and this has been in operation with Mortons for about six months. Then, the 10 Marathons being used by Overland to Iran are equipped with Dunlop Maxarets.

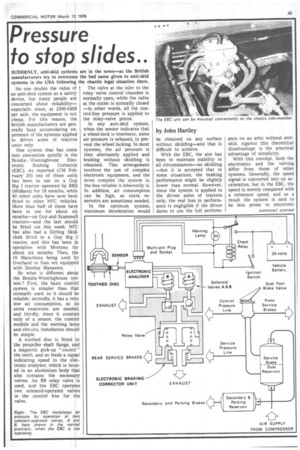

So what is different aboUt the Bendix-Westinghouse system ? First, the basic control system is simpler than that normally used, so it should be reliable; secondly, it has a very low air consumption, so no extra reservoirs are needed; and thirdly, since it consists only of a sensor, the control module and the warning lamp and circuits, installation should be simple.

A toothed disc is fitted to the propeller shaft flange, ahd a magnetic pick-up " counts " the teeth, and so feeds a signal indicating speed to the electronic analyser, which is housed in an aluminium body tbat also contains the necessary valves. An R8 relay valve is used, and the EBC operates two solenoid-operated valves in the control line for the valve. are in the news—as the British the bad name given to anti-skid the chaotic legal situation there.

The valve at the inlet to the relay valve control chamber is normally open, while the valve at the outlet is normally closed —in other words, all the control-line pressure is applied to the relay-valve piston.

In any anti-skid system, when the sensor indicates that a wheel-lock is imminent, some air pressure is released, to prevent the wheel locking. In most systems, the air pressure is then alternately applied and braking without skidding is obtained. This arrangement involves the use of complex electronic equipment, and the more complex the system is, the less reliable it inherently is. In addition, air consumption can be high, so extra reservoirs are sometimes needed.

In the optimum system, maximum deceleration would be obtained on any surface without skidding—and that is difficult to achieve.

With the EBC, the aim has been to maintain stability in all circumstances—no skidding —but it is accepted that in some situations, the braking performance might be slightly lower than normal. However, since the system is applied to the driven axles of tractors only, the real loss in performance is negligible if the driver dares to use the full perform ance on an artic without antiskid. Against this theoretical disadvantage is the practical advantage of simplicity.

With this concept, both the electronics and the valving differ from those of other systems. Generally, the speed signal is converted into an acceleration, but in the EBC, the speed is merely compared with a reference speed, and as a result the system is said to be less prone to electronic