RUNNING, UPKEEP AND OVERHAUL.

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions• from Maintenance Engineers, Drivers and Mechanics.

Preventing Broken Petrol Pipes.

FROM High Wycombe a correspondent, " F.H.B.IL," writes us -saying that in the article which appeared in our issue of January 8th, headed, Some One Ought • to Tell Them of It," there was a method described in which: a petrol pipe was held in a union made especially for the purpose, by means of string, wound round the tube to act as does packing in a stuffing box.

Our correspondent tells us that he can go one better than this by using the ordinary union and nut Provided

lvith the conventional petrol pipe. • He simply takes the nipple off the tube and slips on a ring cut from a piece of the rubber gas .tube that most lorry drivers carry with them, first, of course, putting the hut on the pipe. As to the length of the rubber tubing, our correspondent says that he uses a piece Fin. long, as the nut will permit nothing longer. He uses the ordinary. union and nut. The rubber prevents the tube from being affected by vibration and so becoming broken. He has driven .60,925 miles with pipes held in this manner, without a single breakage, although before using this plan he, was continually having trouble. We have taken the trouble to ascertain from him what effect the .-petrol has upon the rubber; he tells us that the decomposition is net appreciable. If he has to take a pipe down•to clean ' tint the carburetter he has to renew the rubber ring. We look upon this as a very important suggestion, and can fully appreciate the effect it has in preventing vibration front causing break

age of the pipes. '

, An Electric Lighting Trouble.

AN experience of "H.C.IsT." of Harlesden, is interesting in that it points out a moral to other users of vehicles :ivith electric lighting equipment.

One night, when driving, all the lights went out at once without,warning. Inspection revealed that the lamp bulb filaments had binned out. Obviously, it was no use fitting the spares until the cause had been. located and rectified. One bulb was fitted, and it lit up as soon as the switch was operated. When the engine . was raced, to , test whether the dynamo was charging, the bulb gave a brilliant light and then

failed. All wiring connections proved to be sound with the exception of the 'battery terminals, which were very much sulphated. After the terminals had been thoroughly cleaned there was no more

trouble. Since that occasion our correspondent has inspected the battery regularly for traces of similar sulphation, and he recommends that other readers should (h)

An Unusual Tipping Job.

WE hear from " J.NleL.," of Bonny

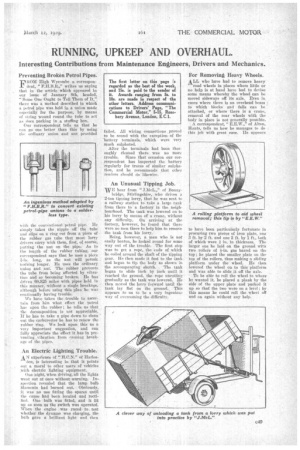

bridge, Stirlingshire, who drives a .2-ton tipping lorry, that he was sent to a railway station to take a large tank from there to a factory in the neighbourhood. The tank was lowered on to his lorry by means of a crane, without any difficulty. On arriving at the factory, however, he found that there were no men there to help him to remove the tank from his lorry. Being, however, a man who is not easily beaten', he looked round for some way out of the trouble. The first step was to get crepe, the ends of .which he coiled around the shaft of the tipping gear. • He then made it fast to the tank and began to tip the body_ as shown -in

the accompanying sketch. tank began to slide inch by inch until it reached the ground, the rope uncoiling gradually as the tank was lowered._ He then 'flayed the lorry forward Until the tank lay flat on the ground... This • appears to us to be a very ingenious way of overcoming the difficulty. For Removing Heavy Wheels.

ALL who have had to remove heavy

road wheels in places where little or no help is at hand have had to devise some means whereby the wheel can be moved sideways off its axle. Even in cases where there is an overhead beam to which blocks and falls can be attached, or where there is a crane, removal of the rear wheels with the body in place is not generally possible.

A correspondent, "E.E.W.," of Alton. Hants, tells us how he manages to do this job with great ease. He appears

to have been particularly fortunate in Procuring two pieces of iron plate, one 3 ft. by 2 ft. and one 2 ft. by 1 ft., both of which were in. in thickness. The larger one he laid on the ground with two rollers of Fin. gas barrel on the top; he placed the smaller plate on the top of the rollers, thus making a sliding platform under the wheel. He then lowered the wheel on to thisplatform and was able to slide it off the axle.

• To be able to roll the wheel to whore he wanted it, he placed a plank by the side of the upper plate and packed it up so that the two were on a level; by this means he could roll the wheel off And on again without ally help.