Quick, Safe, Quiet and Accessible

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

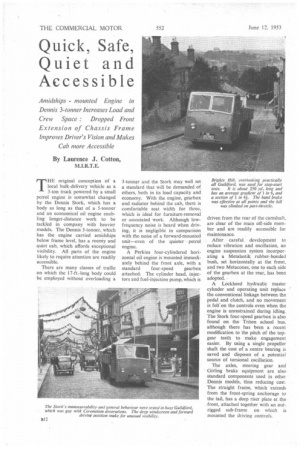

Amidships mounted Engine in Dennis 3-tonner Increases Load and Crew Space : Dropped Front Extension of Chassis Frame Improves Driver's Vision and Makes Cab more Accessible By Laurence J. Cotton,

M.I.R.T.E.

THE original conception of a local bulk-delivery vehicle as a 3-ton truck powered by a small petrol engine is somewhat changed by the Dennis Stork, which has a body as long as that of a 5-tonner and an economical oil engine enabling' longer-distance work to be tackled in company with heavier models. The Dennis 3-tonner, which has the engine carried amidships below frame level, has a roomy and quiet cab, which affords exceptional visibility. All parts of the engine likely to require attention are readily accessible.

There are many classes of traffic on which the 17-ft.-long body could be employed without overloading a 3-tonner and the Stork may well set a standard that will be demanded of others, both in its load capacity and economy. With the engine, gearbox and radiator behind the cab, there is comfortable seat width for three, which is ideal for furniture-removal or associated work. Although lowfrequency noise is heard when driving, it is negligible in comparison with the noise of a forward-mounted unit—even of the quieter petrol engine.

A Perkins four-cylindered horizontal oil engine is mounted immediately behind the front axle, with a standard four-speed gearbox attached. The cylinder head, injectors and fuel-injection pump, which is driven from the rear of the camshaft, are clear of the main off-side member and are readily accessible for maintenance.

After careful development to reduce vibration and oscillation, an engine suspension system incorporating a Metalastik rubber-bonded bush, set horizontally at the front, and two Metacones, one to each side of the gearbox at the rear, has been adopted.

A Lockheed hydraulic master cylinder and operating unit replace the conventional linkage between the pedal and clutch, and no movement is felt' on the controls even when the engine is unrestrained during idling. The Stork four-speed gearbox is also found on the Triton school bus, although there has been a recent modification to the pitch of the topgear teeth to make engagement easier. By using a single propeller shaft the cost of a centre bearing is saved and disposes of a potential source of torsional oscillation.

The axles, steering gear and Girling brake equipment are also standard components used in other Dennis models, thus reducing cost. The straight frame, which extends from the front-spring anchorage to the tail, has a deep riser plate at the front, attached together with an outrigged sub-frame on which is mounted the driving controls. The gear lever is remotely mounted on the riser plate and at the opposite side of the driving seat is the hand brake, having a cranked lever which affords ample power but does not restrict entry to the cab.

Immediately behind the riser plate is a light pressed-brass radiator, which, because of its close proximity to the riser, might, I thought, be likely to cause overheating. The tests proved my assumption to be incorrect and, like most underfloorengined chassis, the Stork is, if anything, overcooled.

On the test vehicle the fan and dynamo were driven through a mechanically jointed shaft operated from the crankshaft and at certain periods there was noticeable rattle. Subsequent production models will have a rubber-cushioned shaft, which should effectively rid the auxiliary drive of noise.

Another recent development in the Stork is the transfer of the fuel filter from the gearbox to a point outside the frame, where it is easier to reach for bleeding or replacing the cartridge.

The lorry was fitted with a 7-ft.

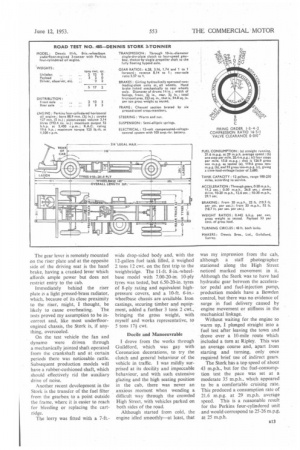

wide drop-sided body and, with the 12-gallon fuel tank filled, it weighed 2 tons 12 cwt. on the first trip to the weighbridge. The 11-ft. 8-in.-wheelbase model with 7.00-20-in.. 10-ply tyres was tested, but 630-20-in. tyres of 8-ply rating and equivalent highpressure covers, and a 10-ft. 6-in.wheelbase chassis are available. Iron castings, securing timber and equipment, added a further 3 tons 2 cwt., bringing the gross weight, with myself and works representative, to 5 tons 171. cwt.

Docile and Manoeuvrable I drove from the works through Guildford, which was gay with Coronation decorations, to try the clutch and general behaviour of the vehicle in traffic. I was mildly surprised at its docility and impeccable behaviour, and with such extensive glazing and the high seating position in the cab, there was never an anxious moment when wending a difficult way through the crowded High Street, with vehicles parked on both sides of the road.

Although started from cold, the engine idled smoothly—at least, that was my impression from the cab, although a staff photographer stationed along the High Street noticed marked movement in it. Although the Stork was to have had hydraulic gear between the accelerator pedal and fuel-injection pump, production models have a Bowden control, but there was no evidence of surge in fuel delivery caused by engine movement or stiffness in the mechanical linkage.

Without waiting for the engine to warm up, I plunged straight into a fuel test after leaving the town and drove over a 10-mile route which included a turn at Ripley. This was an average course and, apart from starting and turning, only once required brief use of indirect gears.

The Stork has a top speed of about 43 m.p.h., but for the fuel-consumption test the pace was set at a moderate 35 m.p.h., which appeared to be a comfortable cruising rate. This produced a consumption rate of 21.6 m.p.g. at 29 m.p.h. average speed. This is a reasonable result for the Perkins four-cylindered unit and would correspond to 25-26 m.p.g. at 25 m.p.h. Then came the one-stop-per-mile trial over the same route, which, with more normal water and oil temperatures, afforded a return of 20.4 m.p.g. Such would be the normal rate when carrying a full load on the outward and return runs.

Delivery vehicles are often used in dense traffic, and stops might be made every quarter of a mile, apart from delivery halts. A test to simulate such work increased the fuel. consumption rate to 15.8 m.p.g., but the figure would probably have been 9-10 m.p.g. if a petrol engine had been installed.

When trying out Dennis vehicles I adjourn to a level concrete road near Milford for the short performance tests, and as the Hog's Back has to be climbed to reach it, an overheating trial is included. The Stork was kept at 30 m.p.h. near the foot of the incline and top gear was held while the gradient reduced the engine speed steadily down to 600 r.p.m.

kept watch on the water temperature, noting that it was 144° F. at the start and after three minutes of stiff pulling at low engine speed it rose 14 F. and remained at that point until an indirect gear was used. Within a few seconds, of changing gear the water temperature was back to 145° F. These tests were made on a moderately warm day of 62° F., with a light following breeze.

Although there was no. exhaust smoke or haze, the injection pump must have had a fairly high setting, because the acceleration rate was indeed rapid. It took only 26.8 sec. to reach 30 m.p.h. from standstill and the top-gear acceleration rate was equally good, only 29 sec. being required from 10-30 m.p.h.

There is no vacuum servo for the braking system and it should not be necessary, judged by the retardation of the Stork. By applying just sufficient pedal pressure to' avoid wheel locking, stopping distances of 22 ft. and 52 ft. were obtained from 20 m.p.h. and 30 m.p.h. respectively.

To wind up the day's work I drove into Guildford to see how the lorry would fare on ffrights Hill, which is about 250 yd. long and has an average gradient of 1 in 6. With a low ratio of 6.28: 1 in the gearbox and normal-ratio back axle, the vehicle has good climbing capacity and took the incline on part-throttle.

The hand brake was effective when stopping at various points and at one section the Tapley meter registered 1 in Q. Even there the lorry moved off from rest without protest from • the transmission.

The Stork is a chassis above average in construction and behaviour. It will appeal especially to operators who carry large bulk loads or those who take pride in the appearance and performance of their vehicles: Opponents of the underfloorengine design invariably criticize its vulnerability to dirt thrown up by the front wheels or condemn the type because of road clearance below the cylinder block and crankcase. Where the vehicle is operating overseas, on a graded earth road, there is the possibility that their criticism would be justified, but from my observations in this country the flat engine is less prone to collect dust because any oil vapour, which causes dust to cling to the unit when mounted below a bonnet, is carried away.

In its ground clearance amidships, the Stork is on par with any other type of chassis with the spare wheel carried below the frame, the clearance under the power unit being 81 in. when 6.50-in. tyres are fitted.