SIMPLE

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

MECHANICS

Batteries, 5

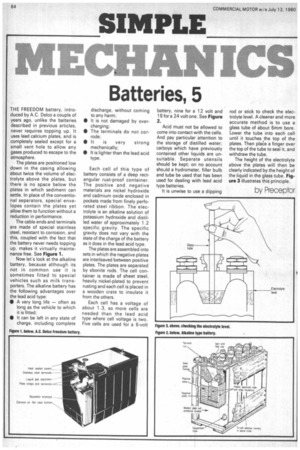

THE FREEDOM battery, introduced by A.C. Delco a couple of years ago, unlike the batteries described in previous articles, never requires topping up. It uses lead calcium plates, and is completely sealed except for a small vent hole to allow any gases produced to escape to the atmosphere.

The plates are positioned low down in the casing allowing about twice the volume of electrolyte above the plates, but there is no space below the plates in which sediment can settle. In place of the conventional separators, special envelopes contain the plates yet allow them to function without a reduction in performance.

The cable ends and terminals are made of special stainless steel, resistant to corrosion, and this, coupled with the fact that the battery never needs topping up, makes it virtually maintenance free. See Figure 1.

Now let's look at the alkaline battery, because although its not in common use it is sometimes fitted to special vehicles such as milk transporters. The alkaline battery has the following advantages over the lead acid type: • A very long life — often as long as the vehicle to which it is fitted; • It can be left in any state of charge, including complete discharge, without coming to any harm: • It is not damaged by overcharging; • The terminals do not corrode; • It is very strong mechanically; • It is lighter than the lead acid type.

Each cell of this type of battery consists of a deep rectangular rust-proof container. The positive and negative materials are nickel hydroxide and cadmium oxide enclosed in pockets made from finely perforated steel ribbon. The electrolyte is an alkaline solution of potassium hydroxide and distilled water of approximately 1.2 specific gravity. The specific gravity does not vary with the state of the charge of the battery as it does in the lead acid type.

The plates are assembled into sets in which the negative plates are interleaved between positive plates. The plates are separated by ebonite rods. The cell container is made of sheet steel, heavily nickel-plated to prevent rusting and each cell is placed in a wooden crate to insulate it from the others.

Each cell has a voltage of about 1 .3, so more cells are needed than the lead acid type where cell voltage is two. Five cells are used for a 6-volt battery, nine for a 12 volt and 18 for a 24 volt one. See Figure 2.

Acid must not be allowed to come into contact with the cells. And pay particular attention to the storage of distilled water; carboys which have previously contained other liquids are unsuitable. Separate utensils should be kept; on no account should a hydrometer, filler bulb and tube be used that has been used for dealing with lead acid type batteries.

It is unwise to use a dipping rod or stick to check the electrolyte level. A cleaner and more accurate method is to use a glass tube of about 6mm bore. Lower the tube into each cell until it touches the top of the plates. Then place a finger over the top of the tube to seal it, and withdraw the tube.

The height of the electrolyte above the plates will then be clearly indicated by the height of the liquid in the glass tube. Figure 3 illustrates this principle.

by Preceptor