AL WAY ON TAP

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

HIGH standards of administrative control an maintenance procedure must be kept by the Coln Valley Water Co., because their fleet of 4 vehicles has to be in constant readiness to meet emer gencies. In 1947, the company's transport departmen was reorganized and Mr. W. Griffiths-Elsden wa appointed manager. it was d‘cided -to standardize upo Austin vehicles and the fleet now comprises two 5-toi steel-bodied tippers with Edbro equipment, a 5-toi

long-wheelbase tipper and two forward-control longwheelbase 5-ton lorries.

There are also three 3-ton forward-control vans with bodies of special design, a 2-tanner with a tilt, two 30-cwt. vans, seven 25-cwt. vans and, in the light category, 15 10-cwt. and 5-cwt, vans, also four 10-cwt. utilities and a pick-up. An Atlas compressor with roadbrea king equipment is based upon a 25-cwt. chassis. The concern also have a Thornycroft Amazon chassis upon

which a Coles 5-ton crane is mounted, a Rapier 3-ton mobile crane, a Brockhouse tractor and a FordsonHolman Tractair outfit. An Ingersoll-Rand roadbreaking unit and two ex7W.D. 250-gal. emergency water tanks arc based on trailer chassis.

Constituted by Act of Parliatnent, the company supply water to an area of 81 sq. miles on the boundary of Hertfordshire and Middlesex. Population in •the district exeeeds 570,000 and with the growth. of industry and housing estates,: new works have been and are being undertaken to increase water supply. Disposition of the company's reservoirs, pumping stations anddepots is illustrated in the accompanying map_ Mr. John Cockram, director and. general manager, is the new president of the British Waterworks Association and is chairman of the Water Companies' Association.

• The two forward control 5-ton lorries are employed by the distribution department to carry pipes. They have a platform length of 16 ft. 6 in. When 18-ft. pipes are carried, there is less overhang at the rear than was the case when normal control vehicles with 12-ft. 71-in. bodies were employed.

Lacking a railway siding in their Bushey works, the company transport all stocks of lime used in the water-softening process from the nearby railway goods yard. One of the 5-ton tippers is used for this purpose and approximately 10 tons of lime are manhandled from railways trucks and delivered to the works each day. In addition, all coal has also to be transported from railhead, and for this work the other 5-ton steel-bodied tipper and the 5-ton longwheelbase tipper are used.

The last-mentioned vehicle was first put into service in 1949 for pipe and plant carrying. It was taken off this work on the introduction of the forward-control lorries, and has covered over 140,000 miles. At a recent inspection it was found to have 0.002 in. crankshaft-journal wear and 0.005 in. bore wear. It has been decarbonized only four times.

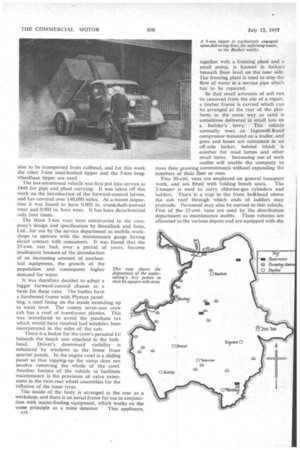

The three 3-ton vans were constructed to the company's design and specification by Bonallack and Sons, Ltd., for use by the service department as mobile workshops to operate with the maintenance gangs having direct contact with consumers. It was found that the 25-cwt. van had, over a period of years, become inadequate because of the introduction of an increasing amount of mechanical equipment, the growth of the population and consequent higher demand for water.

It was therefore decided to adopt a bigger forward-control chassis as a basis for these vans. The bodies have a hardwood frame with Plymax panelling, a steel lining on the inside extending up to waist level. The roomy seven-seat crew cab has a roof of translucent plastics. This was introduced to avoid the purchase tax which would have resulted had windows been incorporated in the sides of the cab.

There is a locker for the crew's personal kit beneath the bench seat attached to the bulkhead. Driver's downward visibility is enhanced by windows in the lower front quarter panels. In the engine cowl is a sliding panel so that topping-up the sump does not involve removing the whole of the cowl. Another feature of the vehicle to facilitate maintenance is the provision of valve extensions in the twin-rear wheel assemblies for the inflation of the inner tyres.

The inside of the body is arranged at the rear as a workshop, and there is an aerial frame for use in conjunction with mains-finding equipment, which works on the same principle as a mine detector. This appliance, together with a freezing plant and a small pump, is housed in lockers beneath floor level on the near side. The freezing plant is used to stop the flow of water in a service pipe which has to be repaired.

So that small amounts of soil can be removed from the site of a repair, a timber frame is carried which can be arranged at the rear of the platform in the same way as sand is sometimes delivered in small lots on a builder's lorry. The vehicle normally tows an Ingersoll-Rand compressor mounted on a trailer, and guns and hoses are contained in an off-side locker, behind which is another for road lamps and other small items. Increasing use of such outfits will enable the company to meet their growing commitments withouf expanding the numbers of their fleet or men.

Two 30-cwt. vans are employed on general transport work, and are fitted with folding bench seats. The 2-tonner is used to carry chlorine-gas cylinders and ladders. There is a trap in the front bulkhead above the cab roof through which ends of ladders may protrude. Personnel may also be carried in this vehicle. Five of the 25-cwt. vans are used by the distribution department as maintenance outfits. These vehicles are allocated to the various depots and are equipped with the toots needed. for the repair and maintenance 'Of Mains_ A 25-cwt. van is used by the transport department for general haulage and administrative work, and is fitted with a Brockhouse towing attachment. The'. remaining 25-cwt. van is held as a spare " maintenance" vehicic.

At one time, the service department inspectors, who are responsible for calling on householders and other consumers, were equipped with motorcycle combinations. This type of transport has now been replaced by Austin A40 10-cwt. vans. Like the distribution department's vehicles, these vans are located at the various depots and work within certain areas.

Two A30 5-cwt _ vans have been newly introduced for work in the Edgware and Pinner districts to show their suitability for this type of work. Having sufficient body iriapacity for their purpose, these vehicles, have returned a greatly improved fuel-consumption rate.

The electrical and mechanical engineering sections have suitably equipped A40 10-cwt. vans, so that maintenance and repair work at pumping stations and installations may be carried.out quickly.

Purity and quality control of water supply is of paramount importance. The chief chemist's department is provided with two M0 vans. These vehicles are primarily used for the collection of samples throughout the 24 hours. They are taken from various check points throughout the area to the laboratory for test.

An A40 pick-up is used by the estates department for the transport of tools and equipment necessary to the maintenance of grounds at humping stations and reservoirs. Two A40 utilities are employed by the distribution department as transport for assistant distribution engineers who supervise the laying, maintenance and repair of mains. An A40 utility is shared by the civil and mechanical engineering departments as transport for survey parties and engineers supervising the installation and maintenance of pumping stations.

The fourth A40 utility is used by the clerk Of works, who is responsible for the upkeep of buildings and properties, for the conveyance of personnel and materials.

Should a main burst, transport facilities play a vita! role in repair operations. The burst is first reported to control, which is manned throughout the 24 hours at head office. Control will then pass details to the duty inspector, who visits the scene of the burst to ascertain the extent of the damage.

If the burst is large, the duty inspector will then alert the foreman inspector and the rest of the district inspectors, who will take action to shut down the main. Inspectors will then issue warning cards to consumers. While these preliminary operations are being carried out, the

aSSistant distribution engineer Will, have been notified of the incident, and Will have had the repair gang, their tti6Wand equipment collected. conveyed to the job. • Later, a Vehicle will go to the pipe dump to collect pipes and materials required for the repair. , If • the circumstances require, the Atlas compressor: and the COles-,mobile Crane will be brought into use. The compressor_ will probably be used to drive a submersible pump. for dewatering the area of the burst, and for breaking up the road surface so that the excavation may be completed before the removal of the damaged main.

The crane will be used to lift portions of the damaged main clear of the excavation, and to locate the replacement pipes. These pipes will have been cut with a mechanical saw driven by air supplied from the mobile corri pressor. Finally, when the excavation has been fined, the area will be consolidated by the use of punners drawing their supply of air from the mobile compressor.

Such an operation, which must be completed speedily so that water supplies are curtailed for the shortest possible time, underlines the need for utmost reliability in transport. To this end, each of the vehicles is brought into the central workshops at Bushey once a month for half a day for servicing and inspection.

Fluorescent lighting is used throughout the workshops and greasing bays. An overhaul programme is compiled weekly as a result of monthly inspections of vehicles. All overhauls to bodywork, engines, gearboxes, chassis and transmission assemblies are carried out in the company's workshops, with the exception of cylinder boring and crankshaft grinding.

Only a small range of fast-moving spares is carried ia the company's stores, as the local Austin main agents premises are near at hand and full use is made of the facilities provided.

A simple filing system gives a complete history of each vehicle in the fleet. Such files carry full details of all work and inspections carried out. Each month a mileage summary is made and passed to the accounts department, who prepare an analysed statement every six months.