N EW GUY 4-5-TON

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

SIX-WHEELER

A Rigid-frame Trailing-axle Model with an Ingenious Load-distribution System Offered at the Attractive Figure of £398 WE are able this week to :announce the introduction, by Guy Motors, Ltd., Fallings Park, Wolverhampton, of an entirely new six-wheeled, forward-control 4-5ton goods chassis, in which a number of interesting features has been incorporated. The chassis is planned on similar lines to the Wolf and Vixen models., but, naturally, there is much novelty in the springs, axle mountings and so forth at the rear, whilst many of the components, notably the frame side-members, cross-bracing, etc., are more robust than in the smaller machines of the range.

The new chassis is to be known as the Guy Fox, and the price has been fixed at £398. The standard tyre equipment comprises 32-in. by 6-in, truck. type front tyres and 32-in. by 7-in. heavy-duty single rear tyres. Alternatively 32-in. by 6-in. heavy-duty tyres all round with twins on all four rear wheels are available, the chassis then costing £418.

In introducing the new vehicle, the company has kept an eye upon both heme and overseas markets. The prices quoted are competitive, . whilst the body space available makes it attractive to operators who have to carry relatively light but bulky loads. With a wheelbase of 13 ft. 14in., the distance from the back of the driver's seat to the end of the frame is 16 ft. 6 ins.

The frame is substantially constructed, having side-members upswept over the two rear axles. Particular attention has been paid to the crossbracing, every member being deep in section with wide gussets, at-the points where they are attached to the sidemembers, to avoid local stressing. There is a dished cross-member to carry the radiator and the front mounting for the engine, both of which components are insulated from the chassis by rubber pads.

Behind the power unit is a channel member with the primary propeller shaft passing thiough its centre; slightly farther to the rear is another deep pressing, housing a central selfaligning bearing for the divided cardan shaft, whilst over the bogie there are B22 three more channel-section members, the centre one of which consists of two gusseted channels, placed back to back, to form a substantial stiffening midway between the two rear axles.

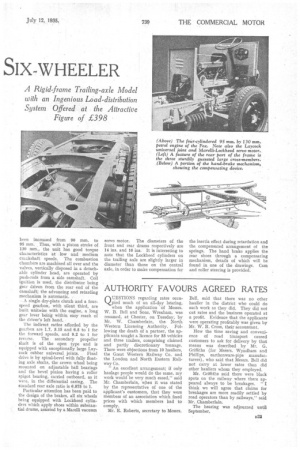

Probably the most interesting features of the design of the whole chassis are connected with the rear sus pension. Only the leading axle is driven, but all four rear wheels are used for braking purposes. The rear assembly is not a true bogie, but there is a compensating bar on each side to allow for movement of the load-carrying wheels to occur, without creating a marked tendency for the load to be taken off any particular wheel.

Actually the compensating mechanism is so designed that 25 per cent. more load is carried by the driving axle than the trailing axle, and, when climbing hills, this ratio is even increased.

Both .axles are suspended on semielliptic springs, the leading axle following contemporary design fairly closely,

whilst the trailing axle is attached to the under side of semi-elliptic springs having a pronounced reverse camber. Between the tvve springs is A, compensating bar which swings ill a. pivot carried by a bracket from the mairi frame. The arms of the compensating bar normally lie horizontally, the rear end of the leading spring being shackled to the after extremity of the bar, whilst the front end of the \rearmost spring is shackled to the forward end of the bar, the leverages being so arranged that they are in the ratio of

4 to S. This, coupled with the fact that the deflection rate of the springs to the leading axle is 25 per cent, greater than that of the rearmost axle, causes an equivalent increase in tyre adhesion to the centre wheels under driving conditions.

Also attached to the compensating bar is a vertically disposed arm which rocks between two rubber-faced stops. As the driving torque builds up, the leading spring is partially deformed, until the arm rests on one of the stops, when increased pressure tends to lift the trailing axle and give greater tyre adhesion to the driving wheels.

Similarly, when the torque reactions are reversed (as when braking) the compensating bar works in the opposite way, giving an increased load on the trailing axle, thereby providing an approximation to equality for all four rear wheels, when the vehicle is being braked hard.

For the rest, the chassis follows largely upon the design of the Guy Vixen. A four-cylindered overheadvalve power unit is three-point mounted on thick rubber cushions.

The particular power unit of .tbeFqx has a rather larger swept volume than the smaller models, for the bore has been increased from 90 mm. to 95 mm. Thus, with a piston stroke of 130 mm., the unit has good torque characteristics 'at lbw and medium crankshaft speeds. The combustion chambers are machined all over and the valves, vertically disposed in a detachable cylinder head, are operated by push-rods from a side camshaft. Coil ignition is used, the distributor being gear driven from the rear end of the camshaft; the advancing and retarding mechanism is automatic.

A single dry-plate clutch and a fourspeed gearbox, with silent third, are built unitwise with the engine, a long gear lever being within easy reach of the driver's left hand.

The indirect ratios afforded by the gearbox are 1.7, 3.15 and 6.5 to 1 for the forward speeds, and 9.2 to 1 for reverse. The secondary propeller shaft is of the open type and is equipped with exceptionally large Lay cock rubber universal joints. Final drive is by spiral-bevel with fully floating axle shafts, the crown wheel being mounted on adjustable ball bearings and the bevel pinion having a roller spigot bearing, carried outboard, as it were, in the differential casing. The standard rear axle ratio is 6.875 to 1.

Particular attention has been paid to the design of the brakes, all six wheels being equipped with Lockheed cylinders which apply shoes within substantial drums, assisted by a Marelli vacuum servo motor. The diameters of the front and rear drums respectively are 14 ins. and 16 ins. It is interesting to note that the Lockheed cylinders on the trailing axle are slightly larger in diameter than those on the central axle, in order to make compensation for

the inertia effect during retardation and the compensated arrangement of the springs. The hand brake applies the rear shoes through a compensating mechanism, details of which will be found in one of the drawings. Cam and roller steering is provided.