A PRIZE OF TEN SHILLINGS is awarded each week to

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

the sender of the best letter which we publish on this page; all others paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being Mention pour employes name, in confidence, as evidence of good faith. Address D., Al, and F. "The Commercial Motor," 1-15, Iloseberv Avenue, London, E.G.

For Reboring Cylinders.

The sender of the following communication has been awarded the Ws. prize this week.

[17b9] "A.P." (Bermondsey) writes :—"On examination of a ear recently brought in for overhaul, I diseovered that the cylinders were worn. They were larger at the bottom end than at the top, necessitating their being lapped out. As this was a job for which our establishment was not properly equipped, had to design and make a tool for the purpose.

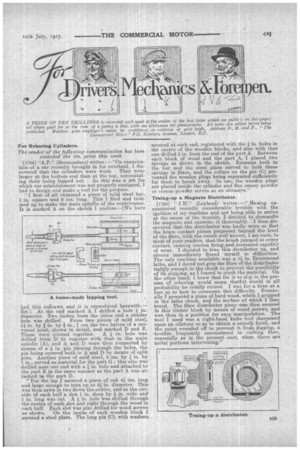

"I first of all obtained a piece of mild steel bar, 1 in. square and 9 ins, long. This I filed and trimmed up to make the main spindle of the contrivance. It is marked A on the sketch I enclose.—{We have had this redrawn and it is reproduced herewith.— En.]. At the end marked A I drilled a hole / in. diameter. Two inches from the other, end a similar hole was drilled. From two pieces of mild steel, 14 in. by in. by I in., I cut the two halves of a universal joint, shown in detail, and marked D and E. These were riveted together. A / in. hole was drilled from D to register with that in the main spindle (A), and A and ID were then connected by means of a / in. pin p`assing through the holes, the pin being secured both in A and D by means of split pins. Another piece of mild steel, 3 ins. by I in. by 1 in., served as material for the part G; this also was drilled near one end with a / in. hole and attached to the part E in the same manner as the part A was attaehed to the part D. "For the lap I secured a piece of oak 4 ins, long and large enough to turn up to 2.1 in. diameter. This was then sawn in two down the centre, and on the outside of each half a slot 1 in. deep by ?-2 in. wide and 1 in. long was cut. A / in. hole was drilled through the centre of each slot and right through the wood in each half. Each slot was also drilled for wood screws as shown. On the inside of each wooden block I secured a steel plate. The long pin (0), with washers secured at each end, registered with the in. holes in the centre of the-wooden blocks, and also with that one drilled 2 in. from the end of the part A. Between each block of wood and the part A, I placed two Aprings as shown in the sketch. Recesses both in the bar and the steel plate served to hold these springs in Pace, and the collars on the pin (0) prevented the wooden plugs being separated sufficiently for them to break away. In use_, the wooden plugs are placed inside the cylinder and fine emery powder or crocus powder serves as an abrasive."

Truing-up a Magneto Distributor.

[1760] • "JR." (Leyland) writes :—" Hauing encountered recently considerable trouble with the ignition of my machine and not being able to arrive at the cause of the trouble, I decided to dismantle the magneto and examine it thoroughly. I then discovered that the distributor was badly worn so that the brass contact pieces projected beyond the level of the fibre, with the result well known, I am sure, to most of your readers, that the brush jumped at every contact, causing uneven firing:and-increased rapidity of wear. I decided to true this distributor up, and almost immediately found myself in difficulties. The only machine available was a 3i in. Drummond lathe, and I dared not grip the fibre of the distributor tightly enough in the chuck to prevent the possibility of ies slipping, as I feared to crush the material. On the other hand, I knew that for it to slip in the process of reboring would mean thattlit would in all probability be totally ruined. I wag for a time at a loss as to how to overcome this difficulty. Eventually I procured a piece of hard wood, which I gripped in the lathe chuck, and the surface of which I then trued. The fibre distributor piece -.was, then secured in this timber block by means of wood screws, and was then in a position for easy manipulation. The tool I used was a right-hand knife tool sharpened upon an oilstone so as to obtain a smootk finish, and the point rounded off to prevent it from digging, a trouble frequently encountered in cutting fibre, especially as in the present case, when there are metal portions intervening."