Limits and fits

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

N THE EARLY DAYS of enjineering when two parts of a :nachine had to fit together, one )art was made and then the ,econd part was accurately nachined so that it fitted corectly to the other.

This method was satisfactory vhere a limited number of lachines were to be manufacured, but with modern mass iroduction this procedure is too low and too expensive. In adlition, when parts wear and lave to be renewed it would be ,ecessary for the replacement 'arts to be machined or handitted. For example, it was not so any years ago that big-end ,earings were hand scraped /hen an engine was overauled.

As the degree of accuracy equired for each dimension in

creases, the cost of production to maintain this accuracy increases at a sharper rate. For these reasons instead of specifying an exact size a nominal size for the part is quoted, and acceptable upper and lower limits for small variations from this size are laid down. For example the diameter of a piston may be shown as 120 +0.05/ —0.00 mm which means that the piston is acceptable if its diameter measures anything between 1 20mm and 120.05mm.

The difference between the upper and lower limit is known as the -tolerance' and in the example quoted above this would be 0.05mm.

In some cases the tolerance is shown in a slightly different way, for example, it is not un

common for the "toe in" on a vehicle's front wheels to be shown as 5 +1.5/-1.5 mm which means the toe in can be anything from 3.5mm to 6.5mm. The tolerance here, of course, is 3mm.

There are several different classes of fits depending on the particular component concerned. They are: (a) Clearance or running fits is where the hole is slightly larger than the shaft which fits in it. Pistons in bores, journals in bearings, valve stems in valve guides, gudgeon pin in pistons are all examples of this kind of fit. The actual amount of gap or clearance depends on the materials of which the components are made, the loads imposed on them, how fast one moves on the other, the amount of lubrication provided and the purpose for which the components are used. A gudgeon pin will have less clearance in a piston than a king pin has in its bush, for example.

(b) Push fits where the force required for assembly is small, eg dowel pin in their holes.

(c) Interference fits in which the shaft is slightly larger than the hole in which it fits so that to assemble the parts some force is needed. This force may be obtained in a press, in a vice or by using a hammer and punch. Bronze bushes fitted into spring eyes or into connecting rod small ends; valve seat inserts, valve guides in cylinder heads, are all examples of this type of fit.

A starter ring on a flywheel is another example of an interference (it, although in this case heat is applied to expand the ring to allow it to fit over the flywheel. When the ring contracts on cooling it becomes an interference fit on the flywheel.

(d) Transition fits which are between the interference and running fit and where the shaft may be either bigger or smaller than the hole into which it fits.

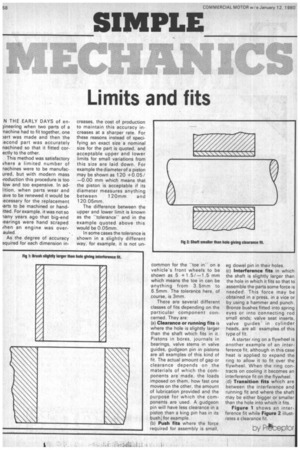

Figure 1 shows an interference fit while Figure 2 illustrates a clearance fit.

Gy PAteotor