Servicing a Large Bus Fleet

Page 89

Page 90

Page 91

If you've noticed an error in this article please click here to report it so we can fix it.

A Review of the Interesting Maintenance Organization of the Eastern Counties Omnibus Co., Ltd., Which Operates Over 600 Vehicles of Many Types

ONE of the most important passenger-vehicle fleets in the country is that run by the Eastern Counties Omnibus Co., Ltd., the head offices of which are at Thorpe Road, Norwich. It is one of the largest 'of the road groups associated with the railway companies—in this case the -London and North Eastern, and the London, Midland and Scottish. The chairman is Mr. J. F. FIeaton, whilst the general manager is Mr. J. Worssam, and the engineer Mr. W. Upjohn.

The fleet comprises 600 buses of the saloon and double-saloon type, and the services cover an area of approximately 5,000 square miles in the counties of Norfolk, Suffolk, Cambridge, Northants, Huntingdon and Essex. Express services run throughout East Anglia, also to London, Newcastle, Liverpool, Leicester, Birmingham, etc. Stagecarriage services utilize some 3,500 miles of road, and the total number of passengers carried annually is about 45,000,000, involving some 19,009,000 miles' running. There are over 2,5i employees.

Perhaps the most striking of .rece: developments is the. bus station as garage in Surrey Street, Norwic opened in March last year. This w house 170 buses and coaches, and remarkable feature is that the ro covers an area of 52,000 sq. ft. wit out a single' pillar, whilst the equi ment is most up to date, including ele trie pumps for fuel and an automat washer, where four buses can I cleaned simultaneously in 21 minute There are 800 ft. of platforms alai the whole length of the station, at these are divided into 19 number( bays with indicator boards to show ti departure points; fixed seats and gla canopies add to the comfort. A. nouncements'of departures and arriva are given by 20 loud-speakers. TI finish is arranged to harmonize wii the general architecture of the city, ar is in red-brown bricks, of which 650,01 were used.

Returning to the fleet, the petr double-deckers include 136 Leylan, 8 Bristol and 2 A.E.C. Petrol salot uses comprise 52 Leyland, 32 Bristol, 13 A.E.C., 18 Gilford, 109 T.S. Exness, 27 Dennis, 64 S.O.S. and 14 of ;undry makes. Amongst the oilmgined double-deckers are 13 Leyland tnd 10 Bristol, whilst single-deckers vith this type of engine include 22

and 10 Bristol. The company dso has on order 4 Bristol doubleleckers and 18 Bristol luxury coaches, di with Gardner oil engines, and in this connection we may mention that ill vehicles ordered in future will have ;ornpression-ignition engines. .

The distribution in the various areas s: Cambridge, 95; Peterborough, 86; :pswich, 98; Norwich, 273. The total s 555, as the winter service is in opera

ion,the summer programme, with an =Teased number of vehicles, beginning ;arly in July.

In addition to ordinary-bus and exaress-bus work, a number of five-day :ours is arranged around the South :oast, Wales, Devon and Cornwall.

At each depot in the areas is a works manager, who controls the engineering dde, the docking staff, running shift md cleaning staff. The engineer is, of ourse, at Norwich, whilst a superin:endent is in charge of the bus station, with its running shift, cleaners, etc. Servicing is carried out on the unit-eplacement system. All the other lepots, such as Cambridge. Ipswich and ?eterborough, receive their overhauled ;ngines, gearboxes, differentials, etc., 'rum the workshops at Cremorne Lane, liorwich. Lorries do the transport c40

duty in connection with the work of unit-changing, making a regular weekly tour of the whole district.

The vehicles come in for docking at regular mileages of between 9,000 and 12,000, and, except in the case of a serious breakdown, instructions as to unit replacement are issued from the head office, where elaborate records are kept.

• One-day Dockings.

Docking at the Norwich works covers the vehicles operated at Cromer, Lowestoft, King's Lynn and Yarmouth. The work here and at the other depots usually occupies one day, except where it is fairly extensive, necessitating, say, a change of cylinders. The cylindei

heads are removed, valves ground, brakes overhauled (and refaced if necessary), the gearbox examined and the automatic changing of scheduled units carried out as required.

In the keeping of records at head office the special Bizada filing system, supplied by Carter-Parratt, Ltd., 16, Victoria Street, London, S.W.1, is utilized. The cards are all held in convenient metal slides, which are, in turn, Mounted in holders which permit them to be turned over like pages. The general arrangement can be observed in one of our illustrations. Each card is marked off at its base in thousands of 'miles, and carries a little metal clip which can be slid along to indicate the mileage covered. Thus, the engineer is able to see at a glance when units are ready for change or whether they are approaching this point.

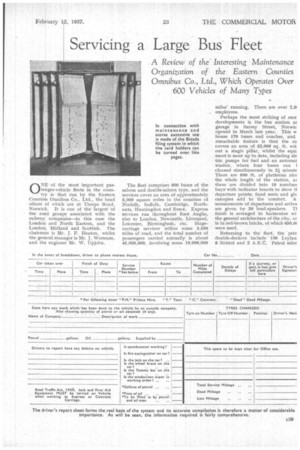

Before starting out each morning every driver is given a daily running record sheet, on which he fills in the time at which he took the vehicle over, the place and the journey number, also entering details of route, delays, etc. At the end of the day, immediately the vehicle runs in, it is refuelled and the details on the running sheet entered on a daily return of fuel and oil, which also acts as a stock report. Any defect mentioned is entered into a " Defects Book," and the foreman then details a man for the work. There are three foremen covering the whole 24 hours, and the incoming foreman signs an acknowledgment for any work left over by the one leaving.

The local depots also send record sheets to head office, where they are entered against the vehicle numbers on the appropriate forms. These show petrol and oil used, mileage, etc: The mileage is then entered on to a main sheet, added up at the end of each week and averages worked out for each vehicle. From this a weekly return is compiled to cover every area, and a separate report is sent to each area in respect of its vehicles. From the main weekly form mileagesare entered on the special cards referred to above, to give the information required for docking, engine overhaul and unit changes.

A Well-equipped Works.

The works at Cremorne Lane are extensive and well equipped, and in addition to overhaul work, carry out such important jobs as the replacement of petrol engines by oil engines, this, in some cases, involving the fitting of new engine cross-bearers, etc. At the time of our visit Gardner four and fivecylindered oil engines and A.E.C. sixcylindered units were being fitted into various makes of chassis.

Other major operations include the removal of the body outriggers on the older Bristols, the bodies now being claimped directly to the side members. It was found that outriggers were apt to work loose.

Curiously enough, in the mounting. of oil engines, it has been found preferable to fit these direct without rubber cushions. This actually appears to restiltin less vibration. The four-cylindered engines are being used for the single-deckers, and five and six-cyiindered units on doublesdeckers and longdistance coaches.

In the unit overhauls the units are first stripped, and the parts placed in sets in containers mounted on small wheels. They are then washed in a boiling mixture of caustic soda and soda silicate, the bath 'consisting of two metal cabinets with wide doors through which the parts pass on trolleys running on lines.

Washing is effected by high-pressure sprays, the pumps for which are elec trically driven. The soda silicate is added to counteract any tendency for the caustic to attack the machined facings of aluminium castings, etc. The same cleansing effect cannot be obtained by reducing the strength of the caustic.

Overhauling Major Units.

The clean parts then go in hatches to an inspection department, where they are checked for wear and rejected for treatment by the salvage. section if necessary. The rest, together with requisitions for new parts, are handed to the fitter.

On unit overhauls the crankshafts are always reground on a Churchill Machine, and all the cylinders are rebored. This applies even when resleevs ing is carried out, the sleeves being left .02 in. small in the bore to allow for final grinding. Great care is taken in this pkocess, which is also carried out on a Churchill machine. All swarf is extracted by suction and taken outside the shop, and even the gauge is lett on the bed of the grinding machine so that it remains at the same temperature as the cylinders.

As regards the crankcases all the brasses are remetalled, new white-metal being used. The crankcase is rigidly bolted down to a metal block with the cylinder-block facing against the latter. The bearings are then fitted into the case and bored out. The importance of using the cylinder-block facing as a guide for this operation is that a case may be slightly sprung, but it will return to normal when the cylinder block is replaced. If, however, boring had been effected while the case was sprung, then binding would occur during erection. Some operators when carrying out this work utilize the sump

face, but this is apt to result in considerable inaccuracy and consequent trouble later oh.

New white-metal is also supplied for the connecting rods, and a lathe has been specially converted to deal with up to six rods at one setting-up. One cutter passes through all the rods, and the faces are trued up and radiused in the same jig.

A large lathe is used for boring brake drums. When these are 'Worn cast-iron sleeves are inserted, and the drums mounted, on hubs carried on cones to duplicate the bearings; they are then finally trued up.

The machine tool equipment also includes a Churchill universal grinder, Herbert radial drill for valve reseating, etc., shaping machines, and an hydraulic universal press' for truing propelIer shafts and similar articles. An interesting outfit is a Premix gas and air incorporator, made by, Premix Gas Plants, Ltd. This supplies a standard mixture of gas and air to the brazing hearths, remetalling benches, etc.

On the electrical bench all dynamo and magneto repairs, with the exception of rewinding, are carried out, and there

is a testing rig for any type of dynamo.

A great deal of reclaim work is carried out in the salvage section in connection with universal joints, kingpins, clutch shafts, etc. Building up of the steel is carried out by electric welding, utilizing welding rods of quail ties to match the materials of thi articles under treatment. • Tyre repairs are not carried out, i having been found more advantageou to send these to the makers' loca depots.

On the engine-test benches four unit can be run-in simultaneously, bu economy in the actual testing plant i attained by utilizing a single Heenas and Froude dynamometer, which i mounted on rails so that it can b moved to each bench as required. Cool

ing water is fed to the units from under ground and taken away overhead ti outside tanks; the exhaust in each Gas. is also taken underground.

The engines are not belted in, beinj started straight away under their owl power, but to avoid difficulty in start ing the dynamometer is itself equippec with an electric starter supplied by separate battery. Each engine is rut for two hours light at about 1,501 r.p.m., and then under full load a some 800-900 r.p.m. for four hours There is a final test for the maximun b.h.p. up to 1,800 r.p.m. A meter indi castes the fuel consumption per h.h.p. hour. The testers make out curves o b.b.p. and fuel consumption, which.an handed in for entry on the appropriat. engine card.