Factors that Make for Smoothness and Silence

Page 86

Page 87

Page 88

If you've noticed an error in this article please click here to report it so we can fix it.

Problems that Beset the Designer of Passenger Vehicles in his Search for Refinement in Performance are Discussed. Elimination of Noise and Vibration Largely a Question of Compromise I.N the past few years the passenger vehicle has entered a new phase, in which one of the major aims of the Lesigner has been to provide—subject

o maintenance and other practical coniderations—a degree of comfort akin o that of the high-grade private car. :hat this object has, to a large extent, leen realized will be generally agreed. gnoring the advantages gained by intorovements in body design and seating,

he way in which vibration has been educed, and the steps that have been aken to ensure quiet and smooth peration, form a subject of special nterest to the operator.

Dealing first with the power unit, vhich may be said to be the primary ause of vibration, the modern petrol ngine has reached a high state of perection, and when, as is generally the ase, it is mounted on rubber, the vibraion transmitted to the chassis, due to orque reaction and unbalanced forces, s almost negligible. The degree of reedom from vibration is, of course, ,eperuknt to a large extent upon the lumber of cylinders. Of the types enerally in use the six-cylindered en'hie is, to all intents and purposes, ler-kali/ balanced and should, therec36

fore, give the maximum refinement in operation.

This question of vibration has been given great prominence in connection with the oil engine, and the increasing popularity of this class of power unit for passenger vehicles has led to an intensive study of its. characteristics in this respect.

It is evident that the compressionignition engine has reached its present position primarily on account of its economy of operation ; the efforts that have been made to bring it into line with the petrol engine on the score of smoothness have, in the nature of things, been a secondary consideration.

it must be admitted that from this point of view the oiler still lags behind, and a well-known protagonist of the petrol engine recently opined that ' it would appear to be harder for the compression-ignition engine to approach the silence, smoothness and refinement of the petrol engine than for the latter to preserve these qualities and approach very appreciably nearer the running costs of the former," With this opinion, not everyone will agree. It is, however, generally accepted that at low speeds the oiler is subject to appreciable vibration. Nevertheless, above the critical period at which the natural frequency of the chassis coincides with the vibration set up by the engine, the oiler of to-day is quite unobtrusive. .

Space precludes an analysis of the factors that are responsible for this characteristic in the oil -engine, and it is, perhaps, more profitable to examine the steps that are being taken to remedy this deficiency. , To overcome difficulties arising from the fact that the oiler is, inherently. prone to suffer from torsional critical speeds, a vibration damper of the friction type is usually incorporated. This is generally located at the forward end of the crankshaft, at which position the maximum torsional deflection will oc_cur. Another asset in dealing with torsional vibration is the use of an hy,draulic coupling or Fluid Flywheel.

MOuntin to Reduce Vibration.

From the points of view of noise and .vibration, the engine should be built as rigidly as ispossible within prescribed limits of weight.Some means for mounting the unit to ensure a .good degree of flexibility is, however, desir. .able if vibration is to be minimized. In many instances the unit is mounted on rubber blocks and reasonable success has attended the various designs of mounting that are based on this principle.

There is, perhaps, room for doubt as to whether the rubber mounting can be considered wholly satisfactory, and it has often been found that its efficiency is dependent upon unduly fine adjustment. In many cases, where the mounting has been incorrectly adjusted, vibration has been increased rather than diminished. Thus, from the maintenance engineer's point of view, the rubber-block type mounting is not by any means foolproof.

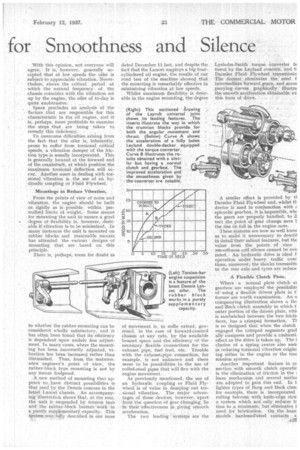

A new method of mounting that appears to have distinct possibilities is that used by the Dennis concern in the latest Lancet chassis; An accompanying 'illustration shows that, at the rear, the unit is suspended by torsion bars and the rubber-hlock bearers work. in a purely supplementary capacity. This

stesu--w-sfid1y described in our issue

dated December 11 last, and despite the fact that the Lancet employs a big fourcylindered oil engine, the results of our road test of the machine showed that the mounting is remarkably effective in minimizing vibration at low speeds.

Whilst maximum flexibility is desirable in the engine mounting, the degree

of movement is, to soihe extent, governed, in the case of forward-control chaSsis at any rate,' by the available bonnet space and the efficiency of the necessary flexible connections for the exhaust pipe, fuel feed, etc.. Trouble with the exhaust-pipe connection, for example, is not unknown and there seem, to be possibilities in the use of coiled-steel pipes that will flex with the engine movement.

As previously mentioned, the use Of an hydraulic coupling or Fluid Flywheel is of value in damning out tor. sional vibration. The major advantages of these devices, however, apart from the question or gear changing, lie in their-effectiveness in giving stnooth acceleration. _ .

The two leading • systernS are the Lyshohn-Srnith torque converter fe turedby the Leyland concern, and II Daimler Fluid Flywheel transrnissio The former eliminates the need f intermediate forward gears, and actor panying curves graphically illustra the smooth acceleration obtainable wi this form of drive.

A similar effect is provided by ti Daimler Fluid Flywheel and, whilst th device is used in conjunction with E epicyclic gearbox, it is impossible, wit( the gears are properly handled, to 'd tect the point of gear change save the rise or fail in the engine note.

These systems are now so well knors as to make it unnecessary to desci-il in detail their salient features, but the value from the points of view smoothness arid silence cannot be ove rated. An hydraulic drive is ideal f operation under heavy traffic conC tions, Moreover, the shocks transmitti to the rear axle and tyres are reduce

• A Flexible 'Clutch Plate.

Where normal plate clutch as gearbox are employed the possibiliti of• using a flexible driven plate in f former are worth examination. An a con-Tanking illustration shows a Bo and:Beek chitch assembly in which f Otter portion Of the driven plate, whii is sandwiched between the two frictic faces, has a crimped formation. TI is so designed that when the clutch engaged the crimped segments grad ally conipress and provide a cushionid effect as the drive is taken up. The i elusion of. a spring centre also assli in reducing torsional vibration originting either in the engineor the trar mission system.

Another important feature in cc nection ,with smooth clutch operatic is the elimination of friction in the lease mechanism and several meth° are adopted to gain this end. In t lighter types of Borg and Beck clutc for exantple, there is incorporated rolling fulcrum with knife-edge stru a system which not only reduces fr tion to a minimum, but eliminates I need for lubrication. On the heav, models hardened:steel contacts a

eedle-roller pivots are incorporated. It is not possible, within the scope f this article, to deal with the many ew designs of gearbox that have been rtroduced within the past two or three ears. Most of these have, as their rinaary object, the simplification of ear changing and a consequent reduc-' on of transmission shock. Any gearox which makes gear changing easy nd produces a tangible reduction in hock to the transmission line will be active in promoting smoothness and ilence. It is obvious, of course, that here are many other practical contderations which must be regarded.

Transmission Periods.

Transmission periods are sometimes raceable to the ,gearbox and, where a ormal crash-type box is used, lack of Lgidity is often the cause of vibration. hort stiff shafts and a rigid casing are enerally the means for minimizing this rouble, if it be confined to the gearox. In many cases, however, the eriod originates elsewhere and investiations must cover more than one of he transmission components.

Universal joints have been brought 3 a high pitch of efficiency and recent evelopments are the needle-roller type aint, and the rubber coupling. One of he best-known needle-roller universal 3ints is the Hardy Spicer, which conists of two one-piece steel forged yokes nth a single trunnion cross and four eedle-bearing assemblies.

These joints can be accurately Glanced, being so formed that there is vailable metal that may be removed. loreover, the tubular propeller shafts

are separately balanced by fitting internally, out-of-balance plugs.

Several important chassis makers are now standardizing the Layrub universal joint and, in the search for smoothness and silence, this rubber joint would appear to have a number of attractions. All relative movement in the coupling is taken by rubber trunnion blocks which are effective in damping torsional vibration.

By eliminating metallic connection between the gearbox and rear axle, the rubber joint should prevent the amplification of noise and vibration from other sections of the transmission line. Thus, other things being equal, it will be seen that the rubber joint has useful attributes.

On the larger passenger chassis the underslung-worm rear axle is almost. universally employed, for the reason that it enables a low floor to be attained. Apart from this, worm drive has a number of advantages, not the least being that it is quiet in operation.

Softer Rear Springs?

In dealing with road vibration a number of factors has to be considered, and, whilst the use of more flexible springs might effect an improvement, this course may bring in its train disagreeable characteristics such as rolling on corners, etc. Possibilities in this connection are the use of softer rear springs in conjunction with a stabilizer, or the use of independent suspension. Weight considerations assume a major problem, however, if any big change is to be made in suspension methods.

Sound-proofing the body has received a good deal of attention recently, and the effect of packing the body panels; the bonnet and front bulkhead with sound-absorbing material continues to be explored. Incidentally, it is desirable that the packing material should be not only fireproof but free frem the risk of attack by vermin, Experiments so far conducted seem to point to the fact that difficulties of weight and cost are likely to retard progress.'

Moreover, it is evident that to effect a noticeable improvement—noticeable, that is, to the ordinary passenger and not only to an audiometer—a scheme of packing and air-spacing must be carried to impracticable extremes.

Isolating Engine Noise.

It is probable then, that for the moment, at any rate, the likelihood of sound-proofing lies mostly in preventing engine noise reaching the body.

Exhaust noise has ceased to be a serious problem, although efforts are constantly being made to reduce, even further, the noise from this source. The absorption-type silencer, incorporating a porous material, is now a popular fitment on passenger chassis. The difficulty experienced with silencers of this type is in dealing effectively with noises in the low-frequency range, these being below the range of the sound-absorbing materials.

It will be seen, then, that the search for refinement in performance covers an extremely wide field. The many problems call, in most instances, for a compromise between the results attainable and the practical considerations involved.