STOP! CAN BRAKING E FICIENCY BE IMPROVED?

Page 82

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

Satisfactory Retardation is Afforded by Modern Passenger-vehicle Brakes, But There are Ways By Which Their Efficacy Can Be Increased We Review a Large Number of Recent Developments That Reveal the Tendencies of the Moment and the Lines Along Which Inventors are Working

0 N more than one occasion in the past we have expressed the view that a braking efficiency above a certain degree. is undesirable. In the case of passenger vehicles, the occupants, by too violent retardation, would be caused considerable Ii.seomfort—perhaps even injury—and certain parts of the chassis and the body would be subjected to extremely heavy stresses. Against this, however, is the argument that it is essential to be able to pull up as quickly as the vehicle in front.

The Fact that Counts.

, The latter view seems at first sight to be incontrovertible and of the greatest importance. The fact remains, however, that, although many private cars can stop from 30 m.p.h. in 35 ft. and few commercial vehicles— passenger or goods—can come to rest from this speed in a shorter distance than 50 ft., stem to stern collisions are relatively infrequent. Of those that do occur, the • majority is caused by inattention or carelessness on the 'part of the drivers of the rearward vehicles, and not by inferiority in their retarding mechanism.

Good drivers know how quickly their machines can be stopped and, so far as possible, travel at appropriate distances behind the vehicles in front, but, in many instances, this is impracticable, for cars will overtake them and put themselves in • the dangerous position. Nevertheless, crashes that would seem, in consequence, to be logically inevitable do not happen.

One can conclude only that' the.argument is founded on a wrong basis and that car drivers, in the main, either cannot, or do not, pull up from 30 m.p.h. in 35 ft.

A Position of Stability.

It would seem that chassis manufacturers in our industry accept this state of affairs, for, reference to records of recent C.M. road tests shows that brakes have not been developed in respect of efficiency beyond the 50-ft. mark. A stage seems to have been reached at which stability is becoming established, and efforts are now being devoted, not so much to increasing overall efficacy, as to diminishing the energy required to cause a given retardation and to enhancing brakes along other

• lines.

• There is, however, no question of the impossible in the matter of further diminishing stopping distances. Whilst foil advantage is taken of the retarding powers of the back wheels—nearly every vehicle can lock them on even the most adhesive of road surfaces—more could be done with the front wheels.

Improvements in Many Directions.

One important modern development is the devising of means for transmitting to the front wheels a degree of braking force proportional to the transference of weight to the rear axle. Other directions in which design has advanced have been in the way of making the brakes more progressive and consistent in action, easier to apply and adjust, smoother, simpler, better equalized, more reliable and capable of functioning for longer periods without attention.

Two examples of mechanism, for directing braking force to the front wheels, when the pedal pressure exceeds a predetermined figure, come to mind. Bendix, Ltd., is responsible for both. One is the well-known c32 Auto• Control, the other a more recent invention. The .first-named, in effect, positively checks the movement ol the rear-brake rod after a certain tension has been reached, thereby causing additional movement of the pedal to be transmitted through the compensating gear to the front brakes.

Leverage Automatically Proportioned.

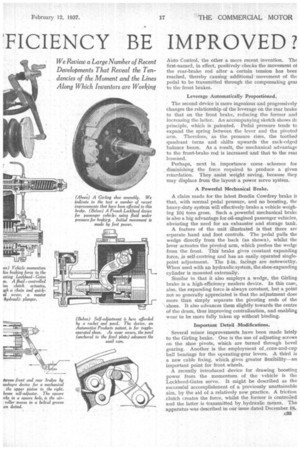

The second device is more ingenious and progressively changes the relationship of the leverage on the rear brake to that on the front brake, reducing the former and increasing the latter. An accompanying sketch shows it principle, which is patented. Pedal pressure tends to expand the spring between the lever and the pivoted arm. Therefore, as the pressure rises, the toothed quadrant turns and shifts upwards the rack-edged balance beam. As a result, the mechanical advantage to the front-brake rod is increased and that to the rear lessened.

Perhaps, next in importance. come • schemes for diminishing the force required to produce a given retardation. They assist weight saving, because they may displace from the layout a power servo system.

A Powerful Mechanical Brake.

A claim made for the latest Bendix Cowdrey brake ie that, with normal pedal pressure, and no boosting, the heavy-duty system will effectively brake a vehicle weighing 104 tons gross. Such a powerful mechanical brake is also a big advantage for oil-engined passenger vehicles, obviating the need for an exhauster and storage tank.

A feature of the unit illustrated is that there are separate hand and foot controls. The pedal pulls the wedge directly from the back (as shown), whilst the lever actuates the pivoted arm, which pushes the wedge from the front. This brake gives constant expanding force, Is self-centring and has an easily operated singlepoint adjustment. The i-in. facings are noteworthy. When used with an hydraulic system, the shoe-expanding cylinder is mounted externally.

Similar in that it also employs a wedge, the Girling brake is a high-efficiency modern device. In this case, also, the expanding force is always constant, but a point not so generally appreciated is that the adjustment does more than simply separate the pivoting ends of the shoes. It also advances them slightly towards the centre of the drum, thus improving centralization, and enabling wear to be more fully taken up without binding.

Important Detail Modifications.

Several minor improvements have been made lately to the Girling brake. One is the use of adjusting screws on the shoe pivots, which are turned through bevel gearing. Another is the employment of .cone-and-cup ball bearings for the operating-gear levers. A third is a new cable fixing, which gives greater flexibility—an important point for front wheels.

A recently introduced device for drawing boosting power from the momentum of the vehicle is the Lockheed-Gates servo. It might be described as the successful accomplishment of a previously unattainable aim, by the aid of a relatively new, practice. A friction clutch creates the force, whilst the former is controlled and the latter is transmitted by hydraulic means. The apparatus was described in our issue dated December

We have noted with interest that the Dewandre Company has developed a servo system in which the hand brake, as well as the foot brake, is boosted. A suggestion that this should be done was made by this paper a year or more ago. Another ingenious device of this concern, which was the subject of a recent patent, is a mechanism designed to improve the " feel" of the brake. It is sketched diagrammatically. Briefly, alternative pedal axes are provided, The lever moves first on the upper axis until the valve is opened. Then the lower axis is used until more foot pressure is exacted, and so on.

There is another plan in which the hand brake is involved, but with a different, although meritorious, object. The Feeny and Johnson company is responsible for it. It is applicable to chassis on which the hand brake shoes are separate from those applied by the pedal. So soon as a predetermined pressure in the foot hydraulic system has been attained, a valve begins to open and a servo unit is caused to apply the hand brake shoes.

We illustrate a unit of this concern which incorporates a lost-motion device between the pedal and the bellows. Its function is to relieve the driver of the additional effort required to compress the bellows, in the eventuality

of no vacuum being available. When the bellows is out of action a straight unimpeded pull is given to the master-cylinder pistrin.

A Lockheed scheme, of French origin, for use in conjunction with a power servo system, merits note, its object being to conserve booster energy. Initial depression of the pedal takes up " slack" in the hydraulic system and brings the shoes into contact with the drums. Further movement opens a valve and allows fluid under externally created pressure to bear upon the master piston.

For introducing the advantages of an hydraulic system into a mechanical layout, another French device, the Chaubeyre, is of interest. Fluid from a main cylinder, under pressure imparted by the pedal, exerts equal force on two secondary pistons. These carry the fulcrum points of floating links—one for the front and one for the rear brake. In this way, balanced distribution is ensured.

Self-adjusting mechanisms are no longer a novelty. Among the best known are the Dewandre R.P. and the Lockheed devices, with the working of which most engineers are familiar ; both were described in The Commercial Alotor dated April 10, 1936. There are two ethers, however, of relatively recent introduction_ The Westinghouse is extremely neat and is incorporated in the air-cylinder, piston rod. A roller, on the side of the device, works in a helical groove on the inner surface of the housing, so that angular motion about the piston-rod axis is caused on each stroke. I3y means of two ratchet-toothed dogs this is imparted to a nut on the rod, which is devised to increase its effective length. The nut can turn only when the wear of the friction material permits a stroke long

e34 enough for an extra ratchet tooth to be gathered. An attraction is that wearing stresses are not localized.

An ingenious mechanism, recently patented by the Automotive Products concern, is for use with toggle-operated shoes. In this, the point at which each toggle arm begins to expand its shoe can be advanced by a snail eam. Rotation of the last-named is caused by a fixed pawl engaging ratchet teeth on the oscillating cam wheel. Here, as on the others, there mast be considerable wear before another tooth is picked up.

The same company has also evolved an interesting shoe assembly which incorporates its own servo gear. An accompanying diagram explains its action clearly. There is a little shoe, which can move through a small angle about the drum centre. Its angular motion in either direction lifts, through a cam, a wedge which separates the ends of the main shoes.

Where a pair of brake shoes is operated by a single wedge or cam and both shoes are rigidly pivoted, a self-energizing action is imparted only to the leading shoe. If the pivot be not rigid, the leading shoe will tend to apply the other shoe as well as itself.

A slight difficulty arises in the latter ease, because of a tendency to " grab" or " chatter," whilst in the former the seeend shoe does not do its full share of the work. To overcome both difficulties an arrangement is used, on a certain private car, in which each shoe is mounted and operated separately, the cams being at the leading ends. Our drawing shows the principle of the device and of an operating gear giving equal cam pressure. A snag would seem to be that there is no servo action when the vehicle is running backwards.

Whilst modern mechanical systems may provide ample braking power for machines of moderate capacity, those on vehicles of advanced age do not afford retardation in line with present-day needs. Always responsive to the call, however, the ingenious brains in our industry have evolved a remedy for this state of affairs. Power equipment, expressly designed for attachment to a wide variety of popular chassis—goods as well as passenger—is available. A product of a specialist in this field is the Theed vacuumservo apparatus, which is so constructed that its installation is a simple matter for even a semi-skilled man.

On the developments that have been made in brakedrum material and design, and in friction fabric and its bonding media, many pages could be written, To improvements its these directions very much of recent braking progress is due, but the matter constitutes a highly specialized subject in itself.