The Modern Conception of the Bus Garage A CONSIDERABLE part

Page 101

If you've noticed an error in this article please click here to report it so we can fix it.

of the 1-1 economic success of a road passenger-transport undertaking • depends upon the garage arrangements. Inconvenient buildings with obstructions to manceuvring, such as are presented by stanchions, ni,ay cause much loss of time, apart from the risk of damage.

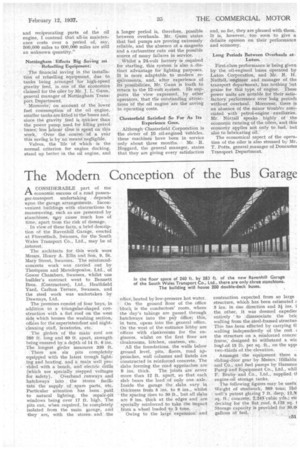

In view of these facts, a brief description of the Ravenhill Garage, erected at Fforestfach, Swansea, for the South Wales Transport Co., Ltd., may be of interest.

The architects for -this work were Messrs. Henry A. Ellis and Son, 9, St. Mark Street, Swansea. The reinforcedconcrete work was carried out by Thompson and Manolopoulos, Ltd„ of Gower Chambers, Swansea, Whilst one builder's contract went to Bennett Bros. (Contractors), Ltd., Ile.athfield Yard, Carlton Terrace, Swansea, and the steel work was undertaken by Dawnays, Ltd.

The premises consist of four bays, in addition to a triangular-shaped construction with a flat roof on the west side which houses the washing section, offices for the superintendent and nightcleaning staff, lavatories, etc.

The girders of the main roof are 280 ft. long and 60 ft. apart, strength being ensured by a depth of 14 ft. 6 ins. The longest girder measures 330 ft.

There are six pits completely equipped with the latest trough lighting and heating', and a main well provided with a bench, and electric drills (which use specially stepped voltages for safety). Overhead runways and hatchways into the stores facilitate the supply of spare parts, etc. Particular attention has been paid to natural lighting, the repair-pit windows being over 17 ft. high. The pits can, when required, be completely isolated from the main garage, and they are, with the stores and the office, heated by low-pressure hot water.

On the ground floor of the office block, is the conductors' room, where the day's takings are passed through hatchways into the pay office; this, in turn, opens into the general office. On the west of the entrance lobby are offices with cloakrooms for the engineers, whilst on the first floor are cloakrooms, kitchen, canteen, etc.

All the foundations, the walls below ground level, pits, floors, road approaches, wall columns and lintels are constructed in reinforced concrete. The slabs forming the road approaches are 9 ins. thick. The joints are never more than 12 ft. apart, so that each slab bears the load of only one axle. Inside the garage the slabs vary in. thickness froiu 5 ins. to 9 ins., whilst the spacing rises to 30 ft., but all slabs are 9 ins, thick at the edges and are specially reinforced to take the impact from a wheel loaded to 3 tons.

Owing to the large expansion and

contraction expected from so large structure, which has been estimated 2 3 ins, in one direction and 3 ins. i the other, it was deemed expedier entirely to disassociate the brie walling from the steel-framed structun This has been effected by carrying ti walling independently of the rest 4 the structure on a reinforced concreframe, designed to withstand a win loail.o.f. 15 lb. per sq. ft., on the uppi two-thirds of the elevation.

Amongst the equipment there a sliding-door gear by Messrs.

and Co., and .fuel pumps by Hammor Pump and Equipment Co., Ltd., whil F. Braby and Co., Ltd., supplied ti engine-oil storage tanks.

The following figures may be used Weight of steelwork, 369 tons; Het well's patent glazing 7 ft. deep, 12,3: sq. ft.; concrete, 2,243 cubic yds.; ste decking for the flat roof, 6,125 sq. Storage capacity is provided for 30,01 gallons of fuel.