CARRYING 85 )1\T LOADS BY TRAILER.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

Some Del with 16W of an Interesting Fowler Product each Fitted with Twin Solid Tyres.

f.A NE of the biggest problems kffacing the haulage contractor who in the course of his work is called upon to deal with the conveyance by road of really heavy loads in the neighbourhood of 100 tons, is to find vehicles which will satisfactorily cope with such immense weights, and this without causing excessive—or, in fact, any —damage to the roads.

In the past, use has been made of trailers equipped with wheels of great width invariably shod with iron, but the crushing effect on the road surface of such wheels when heavily laden may be excessive and, in many cases, they cut into the surface and leave distinct tracks, the depth of the -imprints necessarily depending upon the nature of the road material and the strength Of the foundations. It is obvious that if rubber tyres could be employed for this work, both the vehicle and the road would benefit.

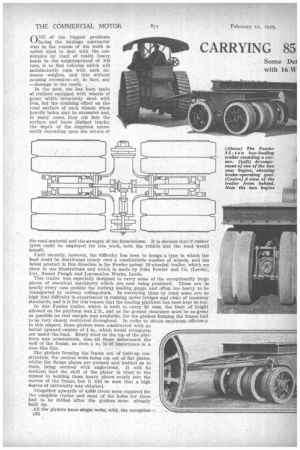

Until recently, however, the difficulty has been to design a type in which the load could be distributed evenly over a considerable number of wheels, and the latest product in this direction is the Fowler patent 10-wheeled trailer, which we show in our illustrations and which is made by John Fowler and Co. (Leeds), Ltd., Steam Plough and Locomotive Works, Leeds.

This trailer was especially designed to carry some of the exceptionally large pieces of electrical machinery which are now being produced. These are in nearly every case outside the railway loading gauge and often too heavy to be transported by railway rolling-stock. In conveying them by road some are so high that difficulty is experienced in running under bridges and clear of tramway standards, and it is for this reason that the loading platform has been kept so low.

In this Fowler trailer, which is built to carry 35 tons, the limit or height allowed on the platform was 2 ft., and as the ground clearance must be as great as possible no real margin was available, for the girders forming the frame had to be very closely restricted throughout. In order to obtain maximum efficiency in this respect, these girders were constructed with an initial upward camber of in., which would straighten out under the load. Every rivet on the top of the platform was countersunk, also all those underneath the well of the frame, as even in. is of importance in a case like this.

The girders forming the frame are of built-up construction, the central wetis being cut out of fiat Wales, whilst the flange plates are pressed and bedded on to them, being secured with angle-irons. It will be realized that the skill of the plater is tried to the utmost in bedding these heavy plates evenly into the curves of the frame, but it will be seen that a high ' degree of uniformity was obtained.

Altogether upwards of 4,000 rivets were .required for the complete• trailer and most of the holes for these had to be drilled after the girders were already built up. • -All the girders have single webs, with the exception c32

of the broad central one, which has a double web with a space between wide enough to accommodate the king-pin of the fore-carriage on which the eight wheels at the front are mounted.

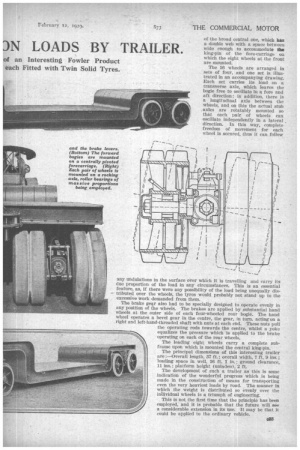

The 16 wheels are arranged in sets of four, and one set is illustrated in an accompanying drawing. Each set carries its load on a transverse axle, which leaves the bogie free to oscillate in a fore and aft direction ; in addition, there is a longitudinal axle between the wheels, and on this the actual stub axles are rotatably mounted so that each pair of wheels can oscillate independently in a lateral, direction. In this way, complete freedom of movement for each wheel is secured, thus it can follow

any undulations in the surface over which it is travelling and carry its due proportion of the load in any circumstances. This is an essential feature, as, if there were any possibility of the load being unequally dis tributed over the wheels, the tyres would probably not stand up to the excessive work demanded from them.

The brake gear also had to be specially designed to operate evenly in any position of he wheels. The brakes are applied by substantial hand wheels at the outer side of each four-wheeled rear bogie. The hand wheel operates a bevel gear in the centre, the gear, in turn, acting on a right and left-hand-threaded shaft with nuts at each end. These nuts pull the operating rods towards the centre, whilst a yoke equalizes the pressure which is applied to the brake operating on each of the rear wheels.

The leading eight wheels carry a complete subframe upon which is mounted the central king-pin. The principal dimensions of this interesting trailer are :—Overall length, 37 ft.; overall width, 7 ft. 9 ins.; loading space in well, 16 ft. 1 in.; ground clearance, 3.1 ins.; platform height (unladen), 2 ft.

The development of such a trailer as this is some indication of the wonderful progress Which is being made in the construction of means for transporting even the very heaviest loads by road. The manner in which the weight is distributed so evenly over the inbividual wheels is a triumph of engineering.

This is not the first time that the principle has been employed, and it is probable that the future Will see a considerable extension in its use. It may be that it could be applied to the ordinary vehicle.