THE CARE of PNEUMATIC TYRES.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

THE new scheme of taxatiou favouring pneumatic-tyred heavy vehicles has caused many to employ pneumatics who never used them before ; at least, on commercial vehicles other than the light types. It may not be appreciated at once that a large proportion of the extra mileage now obtainable from pneumatics is due to the care which is bestowed upon them by their users, who have been educated up to the point of giving that care by actual .Propaganda and even personal demonstration by the tyre manufacturers. It is to the new users that this article, which is really a sequel to one which appeared in our "Outlook Number," dated January 1st, is addressed.

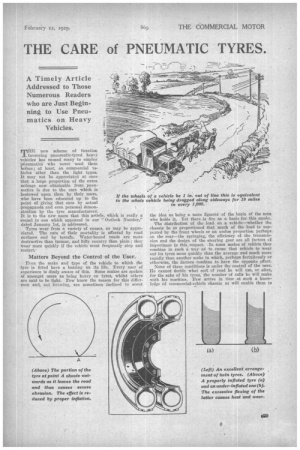

Tyres wear from a variety of causes, as may be appreciated. The rate of their mortality is affected by road surfaces and by terratu. Water-bound roads are more destructive than tarmac, and hilly country than plain ; they wear more quickly if the vehicle must frequently stop and restart. If the wheels to the whole

Matters Beyond the Control of the User.

riven the make and type of the vehicle to which the

tyre is fitted have a bearing on its life, very user of experience is dimly aware of this. Some makes are spoken of amongst users as being heavy on tyres, whilst others are said to be light. Few know the reason for this difference and, not knowing, are sometimes inclined to scout of a vehicle be 1 in. out of line this is equivalent vehicle being dragged along sideways for 19 miles in every 1,000.

the idea as being a mere figment of the brain of the man who holds it. Yet there is fire as a basis for this smoke.

The distribution of the load on a vehicle—whether the chassis be so propartioned that much of the load is supported by the .front wheels or an undue proportion perhaps on the rear—the springing, the efficiency of the transmission and the design of the steering gear are all factors of importance in this respect. In some makes of vehicle they combine in such a way ag to cause that vehicle to wear out its tyres more quickly than the average and much more rapidly than another make in which, perhaps fortuitously or otherwise, the factors combine to have the opposite effect

None of these conditions is under the control of the user. He cannot decide what sort of road he will use, or alter, for the sake of his tyres, the number of calls he will make with his machine. Few arrive in time at such a knowledge of commercial-vehicle chassis as will enable them to select those which are least heavy on tyres, and even if they could they would probably at the same time discover that the chassis which was light on tyres had other disadvantages sufficiently important to turn the decision in favour of one which was more destructive of its tyres.

The Biggest Factor in Tyre Wear.

We may therefore most profitably concern ourselves in this article with those causes of tyre wear which are under the control of the user. Of these the outstanding one, the "big fellow" amongst the demons of tyre destroyers, is misalignment of the wheels. If any one of the four or six wheels of a commercial vehicle be out of line with all the others, that wheel, besides rolling on the ground in company with its fellows, is also being dragged sideways to an extent depending upon the degree of misalignment. To appreciate the effect it is of interest to note that, assuming an average commercial-vehicle wheel to be 1 in. out of line, then for every 1,000 miles which that vehicle travels this particular wheel is being dragged sideways an equivalent of 19 miles. Imagine a fully loaded 5-tonner being towed sideways for 19 miles and try to get an idea as to the probable state of its tyres. That will enable you to understand the very serious nature of the trouble brought about by this fault.

Misalignment may be due to the front wheels not being given a proper amount of " toe-in "-; it may be due to imperfect fitting of any one of the disc wheels which are generally nii'ed for pneumatics ; or it may be brought about by displacement of an axle on its springs as the result of accident or unusual stress of some kind. It is only really within the province of the ordinary user to deal with the first and second of these causes. If he has any suspicion of the third, then he should consult an expert.

The front wheels should have first attention._ They must be set so that they " toe-in " ; that is to say, their front edges must be a little nearer together than those at the rear. This difference must not be more than in. or, at the very outside, I in. and only this latter when definitely aped-fled by the manufacturer of the vehicle.

The tyre makers incline to view in. as the maximum amount of "toe-in." Means for checking this, in the shape

of a simple trammel or gauge, can be bought for a few shillings at any equipment manufacturers. Correction of faulty alignment is usually provided for by right and lef thand screwed ends to the tie-rod of the steering gear. Incidentally, great care should be taken ta fasten very securely the locknuts on this tie-rod after making such an adjustment.

Fitting Disc Wheels.

The other cause of misalignment, that brought about by faulty fitting of disc wheels, has an obvious remedy, provided that the owner appreciates the need for this accurate fitting and how to bring it about.

When replacing a disc wheel which may have been removed for any purpose he should observe that there are hemispherical recesses in the wheel which are intended to engage corresponding shoulders on the studs by which those wheels are secured. These recesses do not, however, imme

030

cliately engage the shoulders on the studs when the wheel is first lifted into place by the mechanic. As might be expected, the holes in the wheel rest upon the studs and if while they are in this position, one only of the securing nuts is tightened with a spanner, then it may well happen that the wheel will be prevented by that circumstance from rising to its proper position on the studs. The preventive of any such occurrence is for the fitter to make sure that the wheel is properly in place and then to screw up the nuts by hand only, at first, taking those in turn which 'are diagonally opposite and going the round until all are finger-tight.

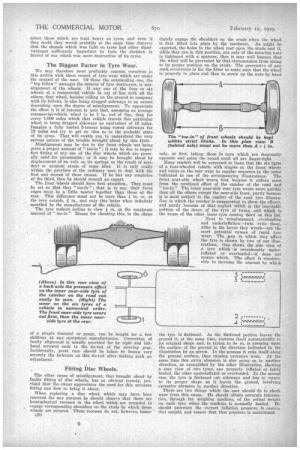

Many readers will be surprised to learn that the six tires of a four-wheeled vehicle with singles on the front wheels and twins on the rear wear in regular sequence in the order indicated in one of the accompanying illustrations. The front near-side wheel wears, first because it suffers most from the combined effect of the camber of the road and "toe-in." The inner near-side rear tyre wears more quickly than all the others except the near-side front, partly because it is most subject to the camber of the road (see illustration in which the camber is exaggerated to show.the effect), and partly because of that 'neglect which is the inevitable portion of the inner of the tyre of twins, and which is the cause of the other inner tyre coming third on this list.

Next to 'misalignment, overloading and underinflation—twin evils these, alike in the havoc they wreck—are the most potential causes of rapid tyre wear. The i'ay in which they affect the tyre is shown by two of our illustrations. One shows the side view of a tyre which ig considerably underinflated or overloaded—it does not matter which. The effect is considerably to increase the amount by which

the tyre is flattened. As the flattened portion leaves the ground it, at the same time, restores itself automatically to its original shape and, in trying to do so, is pressing upon the surface -of the ground in the direction indicated in the illustration by an arrow. In the process it rubs itself along the ground surface, thus causing excessive wear. At the same time this extra abrasion is also going on in another direction, as exemplified by the other illustration, showing a rear view of two tyres, one properly inflated or fairly loaded, the other underinflated or overloaded. In the second case the tyre is flattened out sideways and has to return to its proper shape as it leaves the ground, involving excessive abrasion in another direction.

There are two things which the user should do to check wear from this cause. He should obtain accurate information, through the weighing machine, of the actual weight on each tyre when the maehine is normally loaded. He should ascertain the correct inflation pressure to sustain that weight, and ensure that that pressure is maintained.