HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

483.—Examining. the Tipping Gear on a Foden Wagon.

After the hydraulic tipping gear of a Fodor wagon has been in use for several months, it is advisable to examine the leather washer ,fitted twahe hydraulic piston.

This inspection can be carried out without tipping the body, removing the piston Tod and piston, and hacking the body up in the ordinary way, which is a somewhat laborious task.

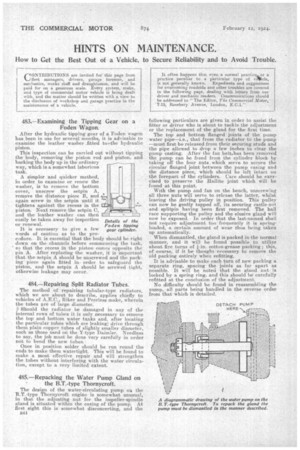

A simpler and quicker method, in order to examine or renew the washer, is to remove the bottom cover, unscrew the setpin A, remove the distance piece B, and again screw in the setpin until it tightens against the recess in the piston. Next remove the setpin C, and the leather washer can then easily be taken away for inspection or renewal.

It is necessary to give a few words of caution as to the procedure. It is essential that the body should he right down on the channels before commencing the task, so that the recess in the piston comes opposite the pin A. After replacing the washer, it is important that. the setpin A should be unscrewed and the packing piece again fitted in• order to safeguard the piston, and the setpin A should be screwed tight, otherwise leakage may occur.

Details of the Fo d en tipping gear cylinder.

484.—Repairing Split Radiator Tubes.

The method of repairing tubular-type radiators, which we are about to describe, applies chiefly to vehicles of A.E.C., Riker and Peerless make, wherein the tubes are of large diameter.

Should the radiator be damaged in any of the . internal rows of tubes it is only necessary to remove the top and bottom water tanks and, after locating the particular tubes which are leaking; drive through them plain copper tubes of slightly smaller diameter, such as those used on the 1-type Daimler. Needless to say, the job must he done very carefully in order not to bend the new tubes.

• Once in position solder should be run round the ends to make them. watertight. This will be found to make a most elective repair and will strengthen the tubes without interfering with the water circulation, except to a very limited extent.

485.—Repacking the Water Pump Gland on the B.T.-type Thornycroft.

The design of the water-circulating pomp oa the B.T.-type Thornycroft engine is somewhat unusual, in that the adjusting nut for the impeller-spindle gland is situated within the casing of the pump. At first sight this is somewhat disconcerting, and the n4.4 following particulars are given in order to assist the fitter or driver who is about to tackle the adjustment or the replacement of the gland for the first time.

The top and bottom flanged joints of the pump water pipe—i.e., that from the radiator to the pump —must first be released from their securing studs and the pipe allowed to drop a few inches to clear the pump casting. After the fan beltahas been removed the pump can he freed froth the cylinder block by taking off the four nuts which serve to secure the circular flanged joint between the pump casing and the distance piece, which should he left intact on the forepart of the cylinders. Care should be exercised to preserve the Halite joint which will be found at this point.

With the pump and fan on the bench, unscrewing all three nuts will serve to release the latter, whilst leaving the driving pulley in position. This pulley can now be gently tapped off, its securing castle-nut and. splitpin having been first remoVed. The ball race supporting the pulley and the elusive gland will now be exposed. in order that the last-named shall not require adjustment to frequently it is springloaded, a certain amount of wear thus being tiken up automatically.

When dismantled, the gland is packed in the normal. manner, and it will be found possible to utilize

about five turns of cotton-grease packing ; this, of course, if it he thought necessary to remove the old packing entirely when refitting.

It is advisable to make each turn of new packing a separate ring, spacing the joints as far apart as Possible. It will be noted that the gland nut is locked by a spring ring, and this should he carefully refitted at the. conclusion of the adjustment.

No difficulty should be found in reassembling the pump, all parts being handled in the reverse order from that which is detailed.