SUPERHEATERS FOR STEAM VEHICLES.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

First Article :—Increasing the Radius of Action of Steam Motor Wagons and Tractors.

IN VIEW of the almost universal adoption of superheating on railway locomotives it is surprising that it has not been more extensively used on steam motor wagons and tractors. The economy of superheating has been .proved conclusively in practice, and is no longer a point left to be debated by engineering professors. Fuel economy on a railway locomotive is almost entirely a question of running cost ; but with steam motor wagons and tractors another very important factor is affected, i.e., the radius of action. The small capacity of the fuel bunker and the necessity for stopping when on the road to fill the water tank are the weakest points in steam: motors, and are the best arguments in favour of petrol motors. Anything which helps to remove this disability of steam motors should be seized upon with avidity, and developed to its full extent.

The use of superheated steam is a very old practice, and was introduced long before the use of compound cylinders, as a means of economy. It fell into disuse on account of lubrication trouble and the difficulty in those early engineering days of constructing the parts to withstand high temperatures. These points no longer present any difficulty to experienced engineers in in fact, they had to be solved before the petrol engine could be successfully used. The use of superheated steam on steam motors has also suffered because of the attempt to apply it through the medium of flash boilers, on the early models of steam buses." No doubt much of the prejudice against its use is because of the trouble experienced with these generators. But the trouble experienced was not due to either of the causes previously mentioned, i.e., lubrication and distortion of parts at high temperatures, but was due to the fact that no suitable means of controlling the temperature and the supply of steam were devised. Recourse-was had to an instrument called the thermostat, which, operated by the expansion and contraction of certain metallic parts, acted upon by the superheated steam, and so regulated the supply of oil fuel to the burner under the boiler. It was, however, impossible to keep the needle of the pressure gauge anywhere near the "red line " 1 • one minute it would be perhaps 100 lb. above, and the next minute 100 lb. below. With a boiler made entirely of solid drawn steel tubes this was not so dangerous as it sounds, but it was too unnerving for the driver, especially one not versed in the " strength of boilers."

It is not now advocated to use superheated steam on those lines, but to apply a superheater to the existing forms of boilers, which will work in unison with them,and which will be easily under control without requiring the use of any other instruments or gauges than those required for saturated steam. . Thoroughly to understand the value of superheated steam it is necessary to have a little knowledge of the theory of steam generation. When steam is generated in an ordinary boiler it is in contact with the water and is called saturated steam. The temperature of . the steam is the same as the temperature of the boiling water, and depends upon the pressure. There is a particular temperature for any given pressure, which for steam at 200 lb. pressure by gauge is 387.7 degrees Fain.. ; the temperature at atmospheric pressure, or zero on the pressure gauge, is 212 degrees.

Saturated steam can be either "wet" or "dry." It is said to be " wet" when minute particles of water are mixed with it ; this steam is visible to the eye as a white vapour and is seen when the safety valve blows off. saturated steam is dry when all the water particles have been evaporated and converted into gas ; this steam is invisible. Steam generated in an ordinary boiler is always "wet," and is spoken of as having a dryness fraction. That is to say, if 1 lb. of the steam contains 1-10 lb. of suspended water particles, its dryness fraction is 0.9. We have ample evidence of wet steam when a boiler primes.

In all stages from boiling water to " dry " saturated steam, the temperature is always the same if the pressure is constant, but the amount of heat required to produce each 1 lb. of steam depends upon the dryness fraction. Take 1 lb. of steam at 200 lb. gauge pressure, its temperature will be 387.7 degre.es, and suppose it is "dry" saturated. The amount of heat required to produce this 1 lb. of steam from water at 60 degrees /temperature will be 1172 British thermal units of heat (the British thermal unit is the amount of heat required to raise the temperature of 1 lb. of water 1 degree Fahrenheit), and its volume' will be 2.124 cubic feet. If this steam is further heated its temperature will increase, and if it is allowed to expand so that its pressure remains the same, its volume will increase in proportion to the increase of temperature. This is called superheated steam, and the in

crease of temperature above that of saturated steam (or the boiling water from which it is produced) is called the degree of superheat.

Taking again 1 lb. of steam at 200 lb. gauge pressure and suppose it has been superheated so that its degree of superheat is 100 degrees Fehr., its temperature will now be 387.7 + 100 = 487.7 degrees. The amount of heat required to produce this 1 lb. of superheated steam from water at 60 degrees will be 1231 British thermal units, or 59 more units than 1 lb. of "dry" saturated steam of the same pressure. Its volume will be 2.45 cubic feet, or .326 cubic feet more than '1 lb. of " dry " saturated steam of the same pressure.

The reason for the gain by using superheated steam is due to the behaviour of the steam in the cylinder. When saturated steam is used, it is already "wet" when it reaches the cylinder, and when it enters the cylinder more of the steam condenses and forms. water, due to the cylinder walls taking= some of the heat out of the steani. The steam, being "wet" to begin with, makes it More easy for this cylinder condensation to take place, for once condensation commences it proceeds with extreme rapidity. Ali the steam which condenses does no work in the cylinder and is therefore entirely wasted. But this condensed steam also causes further loss in the cylinder, because during the exhaust stroke it is re-evaporated by the heat in the cylinder walls. The walls are thus made cooler and more ready to condense the fresh steam which enters the cylinder on the next stroke. This exchange of heat goes qn in spite of the cylinders being jacketed with steam from the boiler.

Now when superheated steam enters a cylinder it gives up a certain amount of its heat to the cylinder walls. It does not cause the steam to condense, but reduces the superheat temperature, consequently there is less heat given up by the steam to the cylinder walls, and there is not the further waste by reevaporating condensed steam during the exhaust stroke.

Superheatedsteam is also less liable to leak than saturated steam, the condensed part of " wet " saturated steam in some mysterious way greatly assists leakage. Therefore there is less steam lost by escaping from the steam chest, between the slide valve and the faces of the ports, into the exhaust port without doing any work in the cylinder.

These fundamental gains are obtained without the expenditure of any more fuel with the type of superheater advocated, the heat used for superheating would otherwise be entirely wasted, passing away out of the funnel. The net result of fitting a superheater is therefore to reduce the amount of steam used by

the engine, which means less fuel and water to be consumed ; also it increases the efficiency of the boiler and causes it to produce more steam for every 1 lb. of fuel burned.

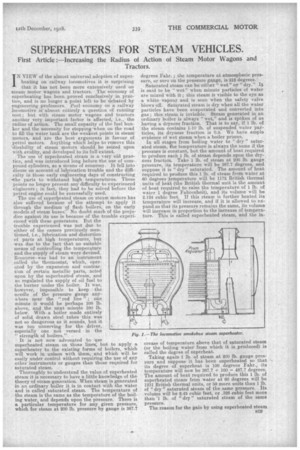

In actual practice the steam is superheated by passing it through a superheater after it leaves the boiler and before it enters the steam chest of the cylinder. In railway practice two systems of superheating the steam have been used. The first system was to place the superheater in the smokebox, where the steam was superheated by the waste heat after it had done all its possible useful work in the boiler. This is illustrated in Fig. 1, and was called low degree superheating, because the degree of superheat added to the steam was not very much ; in fact, the average amount obtained in actual practice was only about 20 to 40 degrees Fahr. This system was eventually abandoned in favour of one where the superheater was placed inside some of the boiler tubes, these tubes being made larger in size to accommodate the superheater coils, as shown in Fig_ 2. The heat which does the superheating in this ease has not done all its useful work in the boiler, and is therefore at a higher temperature.

Consequently, it is possible to superheat the steam to a higher degree, which in practiceamounts to about 250 degrees Fahr. ; this system is called high degree superheating. The second system is more economical, but it requires much more care in manipulation and is more expensive to install. In fact, the low degree system requires no more care than does saturated steam.

But the high degree system requires careful manipulation of the superheat temperature, dampers being used to regulate the flow of the hot gases through the tubes containing the superheater Coils, and a pyrometer is necessary to indicate to the driver the superheat temperature of the steam. A by-pass arrangement is elso necessary, to allow cold air to circulate through the superheater coils when the steam is shut off and the engine is running down hill. The lubrication must also be very good to deal with the high temperatures ; whilst the cylinders and valves must be most carefully designed and constructed of high-class materials to avoid distortion. On account of the very long barrels and, consequently,. long tubes of a railway loco boiler, the temperature of the gases in the smokebox is low, and therefore it is not surprising that the first system was not successful.

When choosing which system to apply to steam motors many points have to be considered. It would naturally be of great advantage as regards economy if the high degree system could be adopted ; but there are very serious obstacles which make its use impracticable.

The greatest obstacle is the care required in its manipulation, which would be even more intricate on a steam motor than on a railway loco, because the conditions under which it works vary to a considerably greater extent.

For instance, the steepest gradient on railways is usually about 1 in 50, but a motor is often called upon to negotiate a gradient of 1 in 6. Then there is not the variation in the resistance of a railway track which is met with on the roads, consequently the variation in power required and, therefore, the demand for steam is much greater on a steam motor than on a railway loco. A loco driver is always an expert man, and has to pass severe tests to obtain his position, and the engine itself is always under expert care.

It is impossible to get these conditions on a steam Motor, therefore the high degree system is impracticable and the low degree system must be chosen. But there is a feature in the design of steam motors, viz., the short boiler barrel, which renders the loee degree or waste heat type more efficient in its action. This feature has always been a serious defect from the point of view of boiler efficiency, but here is an admirable opportunity of turning this defect to useful account. By installing a superheater in the smokebox, the large amount of waste heat which would otherwise be thrown away can be utilizedA much larger degree of superheat can be obtained than on a raileay loco boiler ; in fact, it is possible to get as much as 150 degrees with this type of superheater on a steam motor. This is sufficient to give considerable economy in working and to justify its adoption.